This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

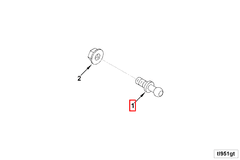

The Throttle Lever Pivot Pin, identified by part number 3357357, is a component manufactured by Cummins, designed for use in heavy-duty trucks. This part serves a pivotal role in the throttle control system, facilitating the precise operation of the throttle lever. Its significance lies in ensuring the smooth and reliable modulation of engine power, which is essential for the efficient and safe operation of heavy-duty vehicles.

Function and Operation

The Throttle Lever Pivot Pin operates within the throttle control system by providing a pivot point for the throttle lever. This allows the lever to move smoothly and accurately in response to driver input. The pin interacts with other components such as the throttle linkage and the accelerator pedal, translating mechanical motion into engine speed adjustments. Its design ensures minimal friction and maximum durability under the demanding conditions typical of heavy-duty truck operation 1.

Key Features

This Cummins part is characterized by its robust design and high-quality materials. Constructed from durable alloys, it is engineered to withstand the rigors of heavy-duty use. Precision machining ensures that the pin fits securely within its housing, promoting smooth operation and longevity. These features contribute to the pin’s reliability and effectiveness in maintaining optimal throttle control 2.

Role in Truck Operation

In the context of truck operation, the Throttle Lever Pivot Pin plays a role in ensuring that the throttle system functions smoothly. This directly affects engine performance by allowing for precise modulation of engine speed in response to driver commands. Smooth throttle operation is vital for maintaining control, especially in varying driving conditions, and contributes to the overall efficiency and responsiveness of the vehicle 3.

Benefits

The advantages provided by the Throttle Lever Pivot Pin include improved throttle response, which enhances driver control and vehicle performance. Additionally, the pin’s durable construction reduces wear on associated components, leading to lower maintenance requirements. Enhanced overall engine efficiency is another benefit, as precise throttle control contributes to optimal fuel consumption and power delivery.

Installation and Maintenance

Proper installation of the Throttle Lever Pivot Pin involves adhering to torque specifications and performing alignment checks to ensure it is correctly positioned within the throttle system. Regular maintenance, including inspection for wear and proper lubrication, is recommended to ensure longevity and optimal performance. Following these guidelines helps maintain the integrity of the throttle control system.

Troubleshooting Common Issues

Common problems associated with the Throttle Lever Pivot Pin may include wear or misalignment. Symptoms such as erratic throttle response or difficulty in modulating engine speed can indicate issues with the pin. Diagnostic procedures involve inspecting the pin for signs of wear or damage and ensuring it is correctly aligned within the system. Repair or replacement may be necessary to restore proper function.

Safety Considerations

When working with the Throttle Lever Pivot Pin, it is important to observe safety practices. This includes proper handling to avoid injury, regular inspection routines to identify potential issues early, and following replacement protocols to ensure the pin is installed correctly and functions safely within the throttle system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and excellence in the automotive industry. The company’s product range includes a variety of engines and components designed for heavy-duty applications, reflecting its dedication to quality and performance.

Cummins Throttle Lever Pivot Pin (Part 3357357) Compatibility

The Cummins Throttle Lever Pivot Pin, identified by part number 3357357, is a critical component in the operation of the throttle mechanism within various engine models. This part is designed to ensure smooth and precise control of the throttle lever, which in turn regulates the engine’s power output.

Engine Compatibility

- 6B5.9 Series

- The Throttle Lever Pivot Pin 3357357 is specifically engineered to fit seamlessly within the 6B5.9 series engines. This series is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The pin’s precision-engineered dimensions ensure it aligns perfectly with the throttle lever, providing consistent performance and longevity.

Importance of the Throttle Lever Pivot Pin

The Throttle Lever Pivot Pin plays a pivotal role in the engine’s throttle system. It acts as a fulcrum point for the throttle lever, allowing for precise adjustments in engine speed and power. The pin’s design ensures minimal friction, which is crucial for maintaining the engine’s efficiency and responsiveness.

Installation and Maintenance

Proper installation of the Throttle Lever Pivot Pin is essential for the optimal functioning of the engine. Technicians should ensure that the pin is correctly aligned and securely fastened to avoid any potential issues with the throttle mechanism. Regular maintenance checks should include inspecting the pin for wear and tear, ensuring it remains in good condition to prevent any disruptions in engine performance.

Role of Part 3357357 Throttle Lever Pivot Pin in Engine Systems

The Throttle Lever Pivot Pin, identified by part number 3357357, is an essential component in the operation of engine systems. It facilitates the smooth and precise movement of the throttle lever, which is integral to controlling the engine’s power output.

Interaction with the Throttle Lever

The primary function of the Throttle Lever Pivot Pin is to provide a pivot point for the throttle lever. This pin allows the lever to rotate smoothly, enabling the operator to adjust the throttle setting with minimal resistance. The pivot pin ensures that the movement of the lever is consistent and reliable, which is vital for maintaining engine performance and responsiveness.

Importance in Engine Control

As the throttle lever is moved, it controls the amount of fuel and air mixture entering the engine. The Throttle Lever Pivot Pin ensures that this movement is transmitted accurately to the carburetor or fuel injection system. This precision is necessary for the engine to respond correctly to the operator’s inputs, whether accelerating, decelerating, or maintaining a steady speed.

Integration with Other Components

Beyond its direct interaction with the throttle lever, the Throttle Lever Pivot Pin also plays a role in the overall integrity of the engine’s control system. It connects to various linkages and cables that transmit the throttle position to other parts of the engine, such as the governor or the electronic control unit (ECU) in modern engines. The pin’s reliable operation ensures that these connections remain secure and functional, contributing to the engine’s overall efficiency and performance.

Conclusion

In summary, the Throttle Lever Pivot Pin (part 3357357) is a fundamental component that enables the precise and smooth operation of the throttle lever, directly influencing the engine’s power output and responsiveness. Its role in connecting and securing various engine control components underscores its importance in maintaining the engine’s performance and reliability.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.