The Cummins 3006453 Throttle Shaft is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to facilitate the regulation of engine speed and power output, which are essential for the efficient and effective performance of the truck. Understanding the function and importance of the throttle shaft can provide valuable insights into the overall operation and maintenance of commercial trucks.

Basic Concepts of Throttle Shafts

A throttle shaft is a mechanical component within an engine that regulates the flow of air and fuel into the combustion chamber. It interacts with the throttle valve, which controls the opening and closing of the air intake, thereby affecting the amount of air and fuel that enters the engine. This regulation is important for maintaining the desired engine speed and power output, ensuring that the engine operates within its optimal performance range.

Purpose of the Cummins 3006453 Throttle Shaft

The Cummins 3006453 Throttle Shaft serves a specific function in the operation of a truck. It is responsible for controlling the engine speed and power output by regulating the flow of air and fuel. This control is achieved through the interaction of the throttle shaft with the throttle valve, allowing for precise adjustments to be made in response to driver input and engine requirements. The throttle shaft’s role in this process is vital for ensuring that the engine operates efficiently and effectively under various driving conditions.

Key Features of the Cummins 3006453 Throttle Shaft

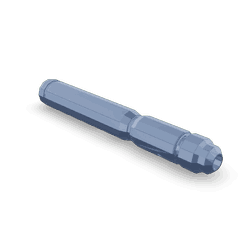

The Cummins 3006453 Throttle Shaft is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring long-lasting operation. Additionally, the throttle shaft may feature unique characteristics such as precision machining and surface treatments that improve its functionality and reliability. These features contribute to the overall effectiveness of the throttle shaft in regulating engine performance.

Benefits of Using the Cummins 3006453 Throttle Shaft

Utilizing the Cummins 3006453 Throttle Shaft offers several advantages for truck operators. These benefits include improved engine performance, enhanced reliability, and increased efficiency. The precise control of air and fuel intake provided by the throttle shaft allows for optimal engine operation, resulting in better fuel economy and reduced emissions. Furthermore, the durability and reliability of the throttle shaft contribute to lower maintenance costs and increased uptime for the vehicle.

Installation and Integration

The installation and integration of the Cummins 3006453 Throttle Shaft into the engine system require careful attention to detail. Proper installation involves aligning the throttle shaft with the throttle valve and ensuring that all connections are secure. It is important to follow manufacturer guidelines and specifications to ensure that the throttle shaft is correctly integrated into the engine system. This process may also involve adjustments to ensure that the throttle shaft operates within the desired performance parameters.

Maintenance and Troubleshooting

Maintaining the Cummins 3006453 Throttle Shaft is crucial for ensuring optimal performance and longevity. Regular inspection intervals should be established to check for signs of wear, corrosion, or damage. Cleaning procedures may be necessary to remove any buildup that could affect the throttle shaft’s operation. Common issues that may arise include sticking or binding of the throttle valve, which can be addressed through lubrication or adjustment. Troubleshooting tips for identifying and resolving problems related to the throttle shaft can help prevent more serious issues from developing.

Performance Impact

The Cummins 3006453 Throttle Shaft has a direct impact on the overall performance of the truck. Its role in regulating engine speed and power output affects fuel efficiency, as precise control of air and fuel intake can lead to more efficient combustion. Additionally, the throttle shaft’s performance influences the truck’s power output and drivability, ensuring that the vehicle operates smoothly and responsively under various conditions.

Manufacturer - Cummins Inc.

Cummins Inc. is a renowned manufacturer in the diesel engine industry, with a history of innovation and commitment to quality. The company’s reputation for producing reliable and high-performance engine components is well-established, making Cummins a trusted name in the commercial truck sector. The Cummins 3006453 Throttle Shaft is a testament to the company’s dedication to providing quality products that meet the demanding requirements of commercial truck operators.

Role of Part 3006453 Throttle Shaft in Engine Systems

The Throttle Shaft, identified by part number 3006453, is integral to the operation of various engine systems. It works in conjunction with the Throttle and Stop Shaft to regulate the airflow into the engine, which directly influences the engine’s performance and efficiency.

Integration with Throttle and Stop Shaft

The Throttle Shaft is designed to interact seamlessly with the Throttle and Stop Shaft. This interaction allows for precise control over the throttle valve, ensuring that the engine receives the correct amount of air for combustion. The Throttle and Stop Shaft mechanism is responsible for setting the maximum throttle position, which the Throttle Shaft must respect to prevent over-revving and ensure safe operation.

Function in Airflow Regulation

In the context of airflow regulation, the Throttle Shaft plays a significant role. It is connected to the accelerator pedal via a series of linkages or cables. When the driver presses the accelerator, the Throttle Shaft rotates, opening the throttle valve. This action increases the airflow into the engine, allowing for more fuel to be combusted and thus delivering more power. Conversely, releasing the accelerator causes the Throttle Shaft to return to a position that reduces airflow, conserving fuel and decreasing engine power.

Interaction with Fuel Injection Systems

In engines equipped with fuel injection systems, the Throttle Shaft’s position is monitored by sensors that send signals to the engine control unit (ECU). The ECU uses this information to adjust the fuel injection timing and quantity, ensuring optimal air-fuel mixture for efficient combustion. This integration enhances the engine’s responsiveness and fuel efficiency.

Role in Idle Control

At idle, the Throttle Shaft maintains a specific position to allow a minimal amount of air into the engine, sufficient to keep it running smoothly without stalling. This is particularly important in modern engines with idle control systems, where the ECU may adjust the Throttle Shaft’s position to maintain a stable idle speed under varying loads, such as when the air conditioning is turned on or off.

Contribution to Emission Control

The Throttle Shaft also contributes to emission control systems. By precisely regulating airflow, it helps ensure that the engine operates within parameters that minimize harmful emissions. This is especially relevant in engines with catalytic converters, where the air-fuel ratio must be tightly controlled to maximize the converter’s efficiency in reducing pollutants.

Conclusion

In summary, the Throttle Shaft (part 3006453) is a key component in the intricate dance of engine operation, working in harmony with the Throttle and Stop Shaft and other systems to deliver performance, efficiency, and compliance with emission standards 123.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.