This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4899132 Threaded Insert is a specialized component designed for use in commercial truck maintenance and operation. This insert is integral to ensuring the longevity and reliability of truck components by providing a secure and durable connection point. Its role in maintaining the structural integrity of various truck parts underscores its significance in the automotive industry.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to reinforce and secure threaded connections within various materials. They function by providing a durable and reliable thread that can withstand repeated use and high stress. In mechanical and automotive engineering, threaded inserts are commonly employed to enhance the strength and longevity of connections, particularly in materials that may not naturally support strong threads, such as aluminum or plastic 1.

Purpose of the Cummins 4899132 Threaded Insert

The Cummins 4899132 Threaded Insert serves a specific role in the operation and maintenance of commercial trucks. It is designed to enhance the structural integrity and functionality of truck components by providing a robust and reliable threaded connection. This insert ensures that critical parts remain securely fastened, even under the demanding conditions typical of commercial truck usage.

Key Features

The Cummins 4899132 Threaded Insert boasts several primary features that set it apart from other threaded inserts. Its material composition is engineered for durability and resistance to wear, ensuring long-lasting performance. The design specifications of this insert are tailored to meet the rigorous demands of commercial truck applications, offering a secure fit and reliable connection. Unique attributes, such as its precision machining and high-quality materials, differentiate it from standard threaded inserts.

Benefits

The Cummins 4899132 Threaded Insert offers a range of advantages for commercial truck applications. Improved durability is a key benefit, as the insert is designed to withstand the harsh conditions and heavy loads encountered in truck operations. Ease of installation is another significant advantage, allowing for quick and efficient replacement or upgrade of existing components. Enhanced performance in demanding conditions ensures that trucks can operate reliably, reducing downtime and maintenance costs 2.

Installation Process

Proper installation of the Cummins 4899132 Threaded Insert involves several steps to ensure optimal performance. Begin by preparing the installation site, ensuring it is clean and free of debris. Use the appropriate tools to insert the threaded insert into the designated location, following the manufacturer’s guidelines for torque specifications and alignment. Best practices include verifying the insert’s secure fit and conducting a test to confirm its functionality before final assembly.

Troubleshooting and Maintenance

Common issues with threaded inserts may include loosening over time or damage from excessive stress. Troubleshooting steps involve inspecting the insert for signs of wear or damage and ensuring it is properly installed. Maintenance tips to prolong the lifespan and effectiveness of the Cummins 4899132 Threaded Insert include regular inspection for wear, proper torque during installation, and replacement as needed to maintain optimal performance 3.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. The company offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins components, including the 4899132 Threaded Insert, are trusted by professionals for their quality, durability, and performance. The reputation of Cummins in the industry underscores the trust placed in their products by commercial truck operators and maintenance professionals.

Threaded Insert 4899132 Compatibility with Cummins Engines

The Cummins Threaded Insert part number 4899132 is a versatile component designed to fit various Cummins engine models. This part is engineered to provide a secure and reliable connection in threaded applications, ensuring durability and performance across different engine configurations.

B Series Engines

- B4.5 CM2350 B135B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 G CMOH6.0 B125

These B series engines, ranging from 4.5 to 6.7 liters, benefit from the threaded insert in various applications, including securing components and ensuring proper alignment.

ISB/ISD Series Engines

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The ISB/ISD series engines, both 4.5 and 6.7 liters, utilize the threaded insert in multiple configurations, ensuring compatibility across different model years and specifications.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, with their distinct design and performance characteristics, also incorporate the threaded insert in various applications, providing a reliable connection for critical components.

ISF Series Engines

- ISF4.5 CM2220 F123

The ISF4.5 engine, known for its performance and efficiency, uses the threaded insert in specific applications to ensure secure and reliable connections.

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850(CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, ranging from 4.5 to 7 liters, incorporate the threaded insert in various configurations, ensuring compatibility across different engine models and specifications.

QSF Series Engines

- QSF3.8 CM2350 F107

The QSF3.8 engine, with its unique design and performance characteristics, also utilizes the threaded insert in specific applications to ensure secure and reliable connections.

The threaded insert 4899132 is a critical component for maintaining the integrity and performance of these Cummins engines, providing a reliable connection in threaded applications across a wide range of engine models.

Role of Part 4899132 Threaded Insert in Engine Systems

The Part 4899132 Threaded Insert is an essential component in various engine systems, facilitating secure and reliable connections between different parts. Its primary function is to provide a threaded interface that allows for the attachment and detachment of components with precision and stability.

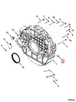

Flywheel Housing

In the flywheel housing, the Threaded Insert ensures a robust connection point for the flywheel. This is vital for maintaining the structural integrity of the housing while withstanding the dynamic forces generated during engine operation. The insert allows for easy replacement and maintenance of the flywheel, ensuring that the housing remains in optimal condition over time.

Housing

For general housing applications, the Threaded Insert offers a versatile solution for attaching various engine components. It provides a consistent and reliable thread that can accommodate different fasteners, making it easier to secure parts in place. This flexibility is particularly beneficial in custom engine builds or modifications, where different components may need to be attached to the housing.

Flywheel

When integrated into the flywheel, the Threaded Insert plays a role in securing the flywheel to the crankshaft or other rotating components. This ensures that the flywheel operates smoothly and efficiently, contributing to the overall performance and reliability of the engine. The insert’s durability and precision threading are key factors in maintaining the flywheel’s alignment and balance.

Long Block

In the context of a long block, the Threaded Insert is used to secure various accessories and components to the engine block. This includes items such as sensors, brackets, and other attachments that are essential for the engine’s operation. The insert provides a strong and stable connection point, ensuring that these components remain securely in place under the high stresses and vibrations of engine operation.

Overall, the Part 4899132 Threaded Insert is a versatile and reliable component that enhances the functionality and maintainability of various engine systems. Its ability to provide a secure and precise threaded connection makes it an invaluable part in the assembly and operation of modern engines.

Conclusion

The Cummins 4899132 Threaded Insert is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its design and features ensure durability, ease of installation, and reliable performance under demanding conditions. By providing secure and precise threaded connections, this Cummins part enhances the functionality and maintainability of engine systems, contributing to the overall reliability and efficiency of commercial vehicles.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.