This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4011698 Threaded Spacer is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s mechanical systems, contributing to the overall maintenance and operation of these heavy-duty machines. Understanding its role and significance can help fleet operators and maintenance personnel ensure the efficient and reliable performance of their trucks.

Basic Concepts of Threaded Spacers

Threaded spacers are mechanical components used to create distance between two parts, provide alignment, or facilitate the distribution of load and stress within a system. In the automotive industry, they are commonly employed to maintain proper spacing and alignment of components, which is vital for the optimal functioning of various systems, including engines and transmissions 1.

Purpose of the Cummins 4011698 Threaded Spacer

The Cummins 4011698 Threaded Spacer is specifically designed to play a role in the operation of commercial trucks. It functions within the engine system, where it helps maintain the correct spacing and alignment of components. This ensures that the engine operates smoothly and efficiently, contributing to the overall performance and reliability of the vehicle.

Key Features

The Cummins 4011698 Threaded Spacer is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for strength and resistance to wear, and its thread specifications, which ensure a secure fit within the engine system. The design of the spacer is also tailored to meet the demanding requirements of commercial truck applications.

Benefits

Using the Cummins 4011698 Threaded Spacer offers several benefits. It contributes to improved engine performance by ensuring proper component alignment and spacing. Its durable construction enhances the longevity of the engine system, potentially leading to cost savings for fleet operators through reduced maintenance and replacement costs 2.

Installation Process

Installing the Cummins 4011698 Threaded Spacer requires careful attention to detail to ensure correct fitting and function. The process involves cleaning the installation area, applying the appropriate lubricant to the threads, and using the correct tools to secure the spacer in place. Following best practices during installation helps maintain the integrity of the engine system and ensures the spacer performs as intended.

Troubleshooting Common Issues

Common issues with threaded spacers may include improper fitting, wear, or damage. Troubleshooting these problems involves inspecting the spacer for signs of damage, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance and inspection can help identify and address these issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4011698 Threaded Spacer, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the spacer and its installation area to remove dirt and debris, and ensuring it remains securely in place. Adhering to these maintenance practices helps maintain the efficiency and reliability of the engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation within the commercial truck industry for producing high-quality, reliable components that contribute to the performance and efficiency of commercial vehicles.

Threaded Spacer Part 4011698 Compatibility with Cummins Engines

The Threaded Spacer part number 4011698, manufactured by Cummins, is a critical component in the assembly of several engine models. This part is designed to provide a secure and stable connection between different engine parts, ensuring proper alignment and functionality.

QSV81G and QSV91G Engines

The Threaded Spacer part 4011698 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The threaded spacer ensures that the components are held together with the correct tension, preventing any misalignment that could lead to operational issues.

QSV91-G4 CM558/CM700 V102 Engine

The QSV91-G4 CM558/CM700 V102 engine also utilizes the Threaded Spacer part 4011698. This engine variant is part of the Cummins QSV series, which is designed for high-performance and durability. The threaded spacer in this engine setup is crucial for maintaining the integrity of the engine’s internal components, ensuring that the engine operates smoothly and efficiently.

General Application

Across these engines, the threaded spacer part 4011698 serves the same fundamental purpose: to provide a secure and precise connection between various engine parts. This ensures that the engine can withstand the stresses of operation and maintain its performance over time. The use of this part in multiple engine models underscores its versatility and importance in Cummins’ engine design.

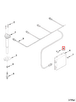

Role of Part 4011698 Threaded Spacer in Engine Systems

The 4011698 Threaded Spacer is an essential component in the assembly and maintenance of various engine systems, particularly within the ignition system. This spacer is designed to ensure precise spacing and alignment between components, which is vital for the optimal performance and longevity of the engine.

Ignition System Integration

In the ignition system, the 4011698 Threaded Spacer is often used to maintain the correct distance between the ignition coil and the engine block or cylinder head. This spacing is important for several reasons:

- Electrical Insulation: Proper spacing ensures that there is adequate insulation between high-voltage components, reducing the risk of electrical arcing.

- Thermal Management: The spacer helps in managing heat dissipation from the ignition coil to the engine block, preventing overheating.

- Mechanical Stability: It provides a stable mount for the ignition coil, ensuring that it remains securely in place during engine operation.

System-Wide Applications

Beyond the ignition system, the 4011698 Threaded Spacer can be found in various other engine components where precise spacing is required. These include:

- Fuel Injectors: Used to maintain the correct gap between the injector and the engine block, ensuring optimal fuel delivery and combustion.

- Sensor Mounting: Employed in the installation of various sensors (e.g., oxygen sensors, knock sensors) to ensure they are positioned accurately for reliable readings.

- Exhaust System: Occasionally used in the mounting of exhaust manifold components to ensure proper alignment and sealing.

The 4011698 Threaded Spacer plays a significant role in enhancing the efficiency and reliability of engine systems by ensuring that components are correctly spaced and aligned. This attention to detail in engine assembly contributes to smoother operation, improved performance, and reduced wear on engine parts.

Conclusion

The Cummins 4011698 Threaded Spacer is a vital component in the maintenance and operation of commercial trucks. Its role in ensuring proper spacing and alignment of engine components contributes to the overall performance and reliability of the vehicle. By understanding its features, benefits, and proper installation and maintenance practices, fleet operators and maintenance personnel can ensure the efficient and reliable performance of their trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.