This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3960077 Threaded Plug is a component designed for use in commercial truck systems. Its primary role is to seal openings within the engine or other systems, preventing the escape of fluids or gases and ensuring the integrity of the system’s operation. This part is integral to maintaining the efficiency and reliability of truck engines, contributing to their overall performance and longevity.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal threaded holes in various systems. They function by being screwed into place, creating a tight seal that prevents leaks. In automotive systems, threaded plugs are commonly used in engines, transmissions, and other fluid-carrying components to maintain system pressure and prevent contamination 1.

Purpose of the Cummins 3960077 Threaded Plug

The Cummins 3960077 Threaded Plug serves a specific function within the operation of a truck. It is designed to seal openings in the engine block or other components, ensuring that fluids and gases remain contained within the system. This plug helps maintain the pressure and integrity of the engine’s systems, contributing to efficient operation and preventing potential damage from leaks.

Key Features

The Cummins 3960077 Threaded Plug is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The plug features a specific thread type that matches the openings it is designed to seal, providing a secure fit. Its design specifications are tailored to meet the demanding conditions of commercial truck engines, ensuring it can withstand high pressures and temperatures.

Benefits

Using the Cummins 3960077 Threaded Plug offers several advantages. It improves system integrity by providing a reliable seal, which helps maintain the efficiency of the engine. The plug’s durable construction ensures longevity, reducing the need for frequent replacements. Additionally, its precise design enhances the overall performance of the truck’s systems, contributing to smoother operation and potentially improving fuel efficiency.

Installation Process

Proper installation of the Cummins 3960077 Threaded Plug is crucial for ensuring optimal performance and safety. The installation process involves cleaning the threaded hole to remove any debris or old sealant. The plug should be screwed into place by hand until it is snug, and then tightened using a wrench to the specified torque setting. Care should be taken to avoid over-tightening, which could damage the plug or the surrounding components.

Common Issues and Troubleshooting

Common problems associated with threaded plugs include leaks due to improper installation, corrosion, or wear. To address these issues, it is important to ensure that the plug is correctly installed and tightened to the proper torque. Regular inspections can help identify signs of corrosion or wear early, allowing for timely replacement. In cases where leaks persist, it may be necessary to inspect the threaded hole for damage or irregularities that could be preventing a proper seal.

Maintenance Tips

Maintaining the Cummins 3960077 Threaded Plug involves regular inspection and cleaning. Inspecting the plug during routine maintenance checks can help identify any signs of wear or damage. Cleaning the plug and the surrounding area can prevent the buildup of debris that could interfere with its sealing capability. If the plug shows significant wear or if leaks are detected, it should be replaced to ensure the continued integrity of the system.

Compatibility and Usage

The Cummins 3960077 Threaded Plug is designed for use in specific applications within commercial trucks. It is compatible with certain engine models and systems, where it plays a role in sealing critical openings. Understanding the plug’s compatibility ensures it is used in the correct applications, contributing to the efficient operation of the truck’s systems.

Manufacturer Information - Cummins

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a reputation for excellence. The company’s dedication to research and development ensures that its products, including the Cummins 3960077 Threaded Plug, meet the rigorous demands of commercial truck applications 2.

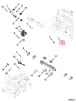

Threaded Plug 3960077 in Cummins Engines

The Threaded Plug 3960077, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to seal and secure various openings within the engine, ensuring that fluids and gases remain contained within the designated pathways.

ISB CM850 Engines

In the ISB CM850 engines, the Threaded Plug 3960077 is utilized in multiple locations to maintain the integrity of the engine’s internal systems. Its primary function is to provide a secure seal in areas where threaded connections are required, such as oil passages, coolant lines, and other fluid pathways. This ensures that there are no leaks, which could otherwise lead to performance issues or engine damage.

Grouping of Engines

The Threaded Plug 3960077 is not limited to the ISB CM850 engines alone. It is also compatible with a range of other Cummins engine models that share similar design and engineering principles. This part’s versatility makes it a staple in many Cummins engine configurations, providing a reliable solution for sealing threaded connections across various engine types.

By ensuring a tight and secure fit, the Threaded Plug 3960077 contributes to the overall efficiency and longevity of the engine, making it an essential component in the maintenance and operation of Cummins engines.

Role of Part 3960077 Threaded Plug in Engine Systems

In the context of engine systems, the 3960077 Threaded Plug serves significant functions within the recirculation and exhaust components.

Recirculation Component

Within the recirculation system, the 3960077 Threaded Plug is instrumental in managing the flow of gases. It ensures that the recirculated gases are directed appropriately, maintaining the efficiency of the system. This plug helps in sealing off specific pathways, allowing for precise control over the recirculation process. Its role is to prevent unwanted leaks and ensure that the recirculated gases contribute effectively to the combustion process, enhancing overall engine performance.

Exhaust Component

In the exhaust system, the 3960077 Threaded Plug plays a key role in sealing connections and preventing leaks. It is often used in the exhaust manifold or other critical junctions where sealing is essential to maintain the integrity of the exhaust flow. By ensuring a tight seal, this plug helps in reducing emissions and improving the efficiency of the exhaust system. It also aids in maintaining the pressure within the exhaust, which is vital for the proper functioning of the engine.

The 3960077 Threaded Plug, through its applications in both recirculation and exhaust components, contributes to the smooth operation and efficiency of engine systems. Its ability to provide reliable sealing and control over gas flow is essential for the optimal performance of these systems.

Conclusion

The Cummins 3960077 Threaded Plug is a vital component in the maintenance and operation of commercial truck engines. Its role in sealing critical openings within the engine ensures the integrity and efficiency of the system. By understanding its features, benefits, and proper installation, technicians can ensure the longevity and performance of the engine. Regular maintenance and timely replacement of this part are crucial for the continued reliability of the truck’s systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.