This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Threaded Stop Plug 3945325 is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is designed for use in commercial trucks, where it plays a significant role in maintaining the integrity of various fluid systems.

Purpose and Function

The Threaded Stop Plug 3945325 serves a vital role in the operation of a truck by sealing and stopping fluid flow in various systems. Its primary function is to prevent the unwanted escape of fluids, ensuring that systems operate efficiently and safely. By providing a secure seal, it helps maintain the pressure and volume of fluids within the system, which is crucial for the proper functioning of the truck 1.

Key Features

This Cummins part is characterized by its threaded design, which allows for a secure fit within the corresponding port. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring durability in demanding environments. The plug’s design and material composition contribute to its reliable performance and longevity in commercial truck applications 2.

Benefits

The use of the Threaded Stop Plug 3945325 offers several benefits. It enhances system integrity by providing a reliable seal that prevents leaks. This, in turn, reduces the risk of system failure and the need for frequent repairs. Additionally, by maintaining the proper fluid levels and pressure, it contributes to the enhanced overall performance of the truck’s fluid systems 3.

Installation and Usage

Proper installation of the Threaded Stop Plug 3945325 is key to ensuring optimal performance and longevity. It is recommended to follow manufacturer guidelines for installation, which may include cleaning the port, applying a compatible sealant, and tightening the plug to the specified torque. Regular inspection and maintenance are also advised to ensure the plug remains in good condition and continues to perform its function effectively.

Troubleshooting and Maintenance

Common issues with the Threaded Stop Plug 3945325 may include leaks or difficulty in removal. Troubleshooting may involve checking for proper installation, inspecting for damage, or ensuring the correct torque has been applied. Maintenance tips include regular inspection for signs of wear or corrosion, and replacement if necessary, to ensure reliable operation.

Compatibility and Applications

The Threaded Stop Plug 3945325 is compatible with a range of truck models and systems, demonstrating its versatility and widespread use in the commercial trucking industry. Its design allows it to be used in various applications where fluid sealing is required, making it a valuable component for fleet managers and maintenance professionals.

Safety Considerations

When working with the Threaded Stop Plug 3945325, it is important to observe safety considerations and precautions. This includes proper handling to avoid damage to the plug or the port, safe storage to prevent contamination, and appropriate disposal practices to protect the environment. Following these guidelines ensures the safety of personnel and the longevity of the component.

Cummins Overview

Cummins is a reputable manufacturer with a long-standing history in the automotive industry. Known for its commitment to quality, Cummins produces a wide range of components designed to meet the demanding requirements of commercial vehicles. The company’s reputation is built on its dedication to innovation, reliability, and customer satisfaction, making it a trusted name in the industry.

Threaded Stop Plug 3945325 Compatibility with Cummins Engines

This part is a versatile component that fits into various engine models. It is designed to provide a secure and reliable sealing mechanism in different applications across multiple engine series.

ISC Series Engines

The ISC series engines, including the ISC CM2150, ISC8.3 CM2250, and ISL CM2150, benefit from the use of the 3945325 Threaded Stop Plug. This part is crucial in ensuring the integrity of the engine’s sealing systems, particularly in areas where threaded connections are required.

ISL Series Engines

The ISL series engines, such as the ISL CM554, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138, also incorporate the 3945325 Threaded Stop Plug. This plug is essential for maintaining the sealing and operational efficiency of these engines, particularly in high-performance and heavy-duty applications.

ISZ Series Engines

The ISZ13 CM2150 Z105 engine utilizes the 3945325 Threaded Stop Plug to ensure proper sealing and prevent leaks in critical areas of the engine.

QSC and QSL Series Engines

The QSC9 CM2250/QSL9 CM2250, QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102, and QSL9 CM850 (CM2850) engines also integrate the 3945325 Threaded Stop Plug. This part is vital in these engines for maintaining the sealing integrity of threaded connections, ensuring reliable performance and longevity.

Role of Part 3945325 Threaded Stop Plug in Engine Systems

This part is an essential component in various engine systems, ensuring the smooth operation and safety of the engine. Here’s how it integrates with several key components:

Engine Brake Systems

In both the 12V Engine Brake Kit and the standard Engine Brake Kit, the Threaded Stop Plug plays a significant role. It helps in managing the flow of fluids or gases within the brake system, ensuring that the brake components function correctly under varying operational conditions. This plug prevents unwanted leaks and maintains the integrity of the brake system, contributing to consistent braking performance.

Fastening and Assembly Components

When used with Hexagon Flange Head Cap Screws, the Threaded Stop Plug aids in securing various engine components. It ensures that screws are properly seated and that there are no gaps or leaks around the screw threads. This is particularly important in high-pressure or high-temperature environments where even minor leaks can lead to significant issues.

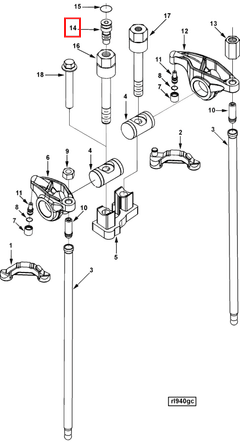

Lever and Rocker Mechanisms

In systems involving Levers, Rockers, and Rocker Lever Assemblies, the Threaded Stop Plug is often employed to seal off fluid passages or to act as a stop mechanism. This prevents the over-extension of levers or rockers, which could otherwise lead to mechanical failure or reduced efficiency. By providing a definitive stop point, it enhances the precision and reliability of these moving parts.

Conclusion

The Threaded Stop Plug 3945325 is a versatile and critical component across a wide range of Cummins engines, providing essential sealing and operational reliability. Its compatibility with various engine series underscores its importance in maintaining the integrity and performance of these engines.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Richard D. Atkins, An Introduction to Engine Testing and Development, SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.