Introduction

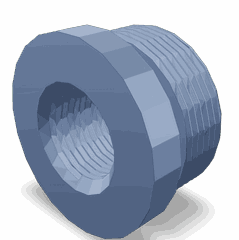

The Cummins 3933340 Threaded Insert is a specialized component designed for use in commercial trucks. It plays a role in maintaining the structural integrity and functionality of various truck components. Its significance lies in its ability to enhance the durability and reliability of truck systems, contributing to overall vehicle performance and longevity.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to reinforce threaded holes in various materials. They are commonly employed in automotive and mechanical applications to provide stronger, more reliable threads than those that can be machined directly into softer materials. Threaded inserts function by being inserted into pre-drilled holes, where they create a durable and precise threading that can withstand significant stress and repeated use 1.

Purpose of the Cummins 3933340 Threaded Insert

The Cummins 3933340 Threaded Insert is specifically designed to play a role in the operation and maintenance of commercial trucks. It enhances the structural integrity of truck components by providing a robust threading solution that can endure the demanding conditions typical of commercial truck usage. This insert ensures that connections remain secure and reliable, reducing the risk of component failure and improving overall truck performance.

Key Features

The Cummins 3933340 Threaded Insert boasts several primary features that distinguish it from other threaded inserts. It is composed of high-quality materials that offer superior durability and resistance to wear. The design specifications of this insert ensure a precise fit and optimal performance. Additionally, it may include unique attributes such as anti-rotation features or enhanced locking mechanisms to further secure its installation 2.

Benefits

The advantages provided by the Cummins 3933340 Threaded Insert include improved durability, which is crucial for components subjected to heavy loads and frequent use. Its ease of installation allows for efficient maintenance and repair processes, minimizing downtime. Furthermore, the insert’s enhanced performance in demanding conditions ensures that commercial trucks can operate reliably under various operational stresses.

Installation Process

Proper installation of the Cummins 3933340 Threaded Insert involves several steps to ensure optimal performance and longevity. The process begins with the preparation of the installation site, which includes cleaning and deburring the hole to ensure a smooth surface. Necessary tools, such as a torque wrench, may be required to achieve the correct installation torque. Following manufacturer guidelines for torque settings and installation procedures is vital to ensure the insert functions as intended 3.

Common Applications

The Cummins 3933340 Threaded Insert finds typical applications within commercial trucks in various components and systems. It is commonly used in areas where secure and durable threading is required, such as in engine components, transmission systems, and chassis parts. Its versatility makes it suitable for a wide range of applications where reliability and strength are paramount.

Troubleshooting and Maintenance

Identifying and addressing common issues related to the Cummins 3933340 Threaded Insert involves monitoring for signs of wear or potential malfunctions. Routine maintenance practices, such as regular inspections and torque checks, can help prolong the service life of the insert. Addressing any detected issues promptly ensures continued reliable performance and prevents more significant problems from arising.

Manufacturer Information - Cummins

Cummins Inc. is a renowned manufacturer within the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a rich history and a diverse product range, Cummins has established a strong reputation for producing reliable and high-performance parts. The company’s dedication to excellence is evident in its continuous efforts to enhance product quality and meet the evolving needs of the commercial trucking sector.

Threaded Insert 3933340 in Cummins Engines

The Threaded Insert 3933340, manufactured by Cummins, is a crucial component in various Cummins engine models. This part is designed to provide a secure and reliable method for attaching other components to threaded holes within the engine’s structure. Its application is vital for ensuring the integrity and functionality of the engine’s assembly.

Application in Specific Engine Models

-

6C8.3 Engines: In the 6C8.3 engine, the Threaded Insert 3933340 is used in several critical areas where threaded connections are necessary. This includes securing components such as bolts and screws to the engine block, ensuring that these parts remain firmly in place under operational stresses.

-

Other Cummins Engines: Beyond the 6C8.3, this threaded insert is also compatible with a range of other Cummins engine models. Its design allows it to be used in various applications where threaded connections are required, providing a consistent and reliable solution across different engine types.

Importance of the Threaded Insert

The threaded insert plays a pivotal role in maintaining the structural integrity of the engine. By providing a threaded hole in materials that may not naturally have one, it allows for the secure attachment of components without damaging the base material. This is particularly important in high-stress environments where components must remain firmly attached to prevent failure.

Installation and Maintenance

Proper installation of the Threaded Insert 3933340 is essential to ensure its effectiveness. It requires precise alignment and the use of appropriate tools to avoid stripping or damaging the insert. Regular maintenance checks should be conducted to verify that the insert remains securely in place and has not loosened over time.

The use of the Threaded Insert 3933340 in Cummins engines underscores the importance of high-quality components in ensuring the longevity and reliability of the engine. Its application in various models highlights its versatility and critical role in engine assembly.

Role of Part 3933340 Threaded Insert in Fuel System Components

In the intricate network of an engine’s fuel system, the threaded insert (part 3933340) plays a significant role in ensuring the seamless operation of various components. This component is integral in maintaining the structural integrity and functionality of the fuel delivery system.

Base Fuel Pump

The threaded insert is utilized in the assembly of the base fuel pump, where it secures critical connections and passages. By providing a robust and reliable thread, it ensures that the fuel lines and other attachments remain firmly in place, preventing leaks and ensuring consistent fuel delivery to the engine.

Fuel Injection Pump

In the fuel injection pump, the threaded insert is employed to attach various components such as fuel lines, sensors, and control units. Its precise threading allows for secure and leak-proof connections, which is essential for the high-pressure environment within the fuel injection system. This ensures that fuel is delivered at the correct pressure and timing, optimizing engine performance.

General Pump Applications

Across different types of pumps within the fuel system, the threaded insert serves as a universal fastening solution. Whether it’s a low-pressure pump or a high-pressure pump, the insert’s design facilitates easy assembly and disassembly, which is beneficial during maintenance and repairs. It also helps in aligning components accurately, which is vital for the pump’s efficiency and longevity.

Fuel Lines and Connections

The threaded insert is also pivotal in the fuel lines and various connections throughout the fuel system. It ensures that all joints are tight and secure, minimizing the risk of fuel leaks. This is particularly important in high-pressure fuel systems where even a small leak can lead to significant performance issues or safety hazards.

Conclusion

In summary, the Cummins 3933340 Threaded Insert is a fundamental component in the fuel system, enhancing the reliability and performance of the base fuel pump, fuel injection pump, and various fuel lines and connections. Its role in providing secure, leak-proof attachments is indispensable for the overall efficiency and safety of the engine’s fuel delivery system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.