This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

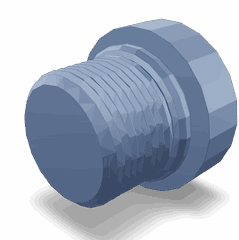

The Cummins 3924789 Threaded Plug is a vital component in commercial truck maintenance, designed to seal openings in various systems to ensure system integrity, prevent fluid leaks, and maintain pressure 3.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal threaded openings in automotive and industrial systems. They function by being screwed into place, creating a tight seal that prevents the escape of fluids or gases. These plugs are commonly used in engine blocks, transmission cases, and other systems where sealing is necessary to maintain system performance and prevent leaks 1.

Purpose of the Cummins 3924789 Threaded Plug

The Cummins 3924789 Threaded Plug is used to seal openings in the engine block or other systems, ensuring that fluids remain contained within the system. This helps maintain system pressure and prevents leaks that could lead to decreased performance or damage to the engine 3.

Key Features

The Cummins 3924789 Threaded Plug is made from high-quality materials that resist corrosion and wear. It features a specific thread type that ensures a secure fit in the corresponding openings. Its design specifications are tailored to meet the demands of commercial truck applications, ensuring reliable performance under various operating conditions 3.

Benefits

Using the Cummins 3924789 Threaded Plug contributes to improved system integrity by effectively sealing openings and preventing fluid leaks. This helps maintain optimal system pressure and enhances overall engine performance. The plug’s durable construction ensures longevity, reducing the need for frequent replacements and maintenance 3.

Installation Process

Installing the Cummins 3924789 Threaded Plug involves cleaning the threaded opening to remove any debris or old sealant. The plug is then screwed into place using the appropriate torque specifications to ensure a secure seal without over-tightening, which could damage the threads. It is important to follow best practices and avoid common pitfalls such as cross-threading or using excessive force during installation 3.

Troubleshooting and Maintenance

Identifying common issues related to threaded plugs, such as leaks or loose fittings, is important for maintaining system performance. Diagnostic methods may include visual inspections and pressure tests to identify the source of any issues. Regular maintenance practices, such as checking for proper torque and inspecting for signs of wear or corrosion, can help ensure the longevity and optimal performance of the Cummins 3924789 Threaded Plug 3.

Common Applications

The Cummins 3924789 Threaded Plug is utilized in various scenarios and systems within commercial trucks. It is commonly found in engine blocks, transmission cases, and other systems where sealing is necessary to maintain system integrity and prevent leaks. Its widespread use in commercial trucks underscores its importance in ensuring reliable operation and performance 3.

Safety Considerations

When handling and installing the Cummins 3924789 Threaded Plug, it is important to observe safety guidelines and precautions to prevent accidents and ensure proper function. This includes wearing appropriate personal protective equipment, following manufacturer instructions for installation, and ensuring that the work area is clean and free from hazards. Adhering to these safety considerations helps maintain a safe working environment and ensures the plug functions as intended 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 2.

Compatibility with Cummins Engines

The Threaded Plug part number 3924789, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This plug is integral to the engine’s operation, providing a secure seal for various applications.

6C8.3 Engine

In the 6C8.3 engine, the 3924789 threaded plug is utilized in several critical areas. It is commonly found in the oil system, ensuring that oil passages remain sealed and preventing leaks. The plug’s design allows it to be screwed into place, providing a tight fit that is essential for maintaining engine integrity 3.

V903 Engine

For the V903 engine, the 3924789 threaded plug serves multiple purposes. It is often used in coolant passages, ensuring that the coolant system remains sealed and free from leaks. Additionally, this plug can be found in other areas where a secure, threaded connection is necessary to maintain the engine’s operational efficiency 3.

Grouping of Engines

Both the 6C8.3 and V903 engines benefit from the use of the 3924789 threaded plug due to its robust design and compatibility with Cummins’ engineering standards. The plug’s threaded nature allows for easy installation and removal, making it a preferred choice for maintenance and repair tasks. Its application across these engines highlights its versatility and importance in ensuring the engines’ longevity and performance 3.

Role of 3924789 Threaded Plug in Engine Systems

The 3924789 Threaded Plug is a critical component in various engine systems, contributing to their efficient operation and reliability. Here’s how it integrates with different components:

Air Heater Starting Aid

In the air heater starting aid system, the 3924789 Threaded Plug is used to seal openings or passages within the heater assembly. This ensures that heated air is directed effectively into the intake manifold, aiding in cold-start performance by warming the incoming air-fuel mixture 3.

Injection Starting Aid

When incorporated into the injection starting aid, the threaded plug helps maintain system integrity by sealing fuel lines or injection ports. This prevents fuel leaks and ensures that the starting aid delivers the correct amount of fuel to the engine during startup, enhancing ignition reliability 3.

Air Intake Heater

Within the air intake heater system, the 3924789 Threaded Plug plays a role in sealing the heater element housing. This ensures that the heated air is delivered consistently to the intake tract, improving combustion efficiency and reducing emissions during cold starts 3.

Full Flow Oil Filter System

In the full flow oil filter system, the threaded plug is utilized to seal off bypass valves or pressure relief ports. This maintains optimal oil flow through the filter media, ensuring that contaminants are effectively removed from the engine oil, which prolongs engine life and maintains performance 3.

Engine Monitoring System

The 3924789 Threaded Plug is also employed in the engine monitoring system to seal sensor ports or pressure taps. This ensures accurate readings from sensors by preventing air or fluid leaks, which is vital for precise engine management and diagnostics 3.

Conclusion

The Cummins 3924789 Threaded Plug is an essential component in maintaining the integrity and efficiency of commercial truck engine systems. Its robust design, compatibility with various Cummins engines, and versatile applications across different engine systems make it a critical part in ensuring reliable operation and performance. Proper installation, regular maintenance, and adherence to safety guidelines are vital to maximizing the benefits of this Cummins part.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.