This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

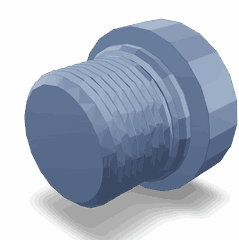

The Cummins 3923960 Threaded Plug is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems. They function by being screwed into place, creating a secure and tight seal that prevents fluid or gas leakage. In automotive and industrial settings, threaded plugs are utilized in a variety of applications, including engine blocks, fuel systems, and hydraulic systems, to maintain system integrity and prevent contamination 1.

Purpose of the Cummins 3923960 Threaded Plug

The Cummins 3923960 Threaded Plug plays a role in the operation of a truck by providing a seal in specific areas where openings need to be closed off. This plug is involved in sealing, pressure management, and maintaining system integrity. By securely fitting into designated ports, it helps in preventing leaks and ensuring that the system operates under the correct pressure conditions 2.

Key Features

The Cummins 3923960 Threaded Plug is characterized by several key features that enhance its functionality and durability. These include its material composition, which is typically designed to withstand the harsh conditions found in commercial truck environments. The thread type is another critical aspect, ensuring a secure fit that resists loosening over time. Additionally, the design specifications of the plug are tailored to meet the specific requirements of its applications, contributing to its overall effectiveness 3.

Benefits

Utilizing the Cummins 3923960 Threaded Plug offers several advantages. It contributes to improved system reliability by ensuring secure seals and proper pressure management. The design of the plug facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, its durability and reliability can lead to long-term cost savings by minimizing the need for frequent replacements or repairs 4.

Installation Process

Installing the Cummins 3923960 Threaded Plug requires following a series of steps to ensure proper fitting and functionality. The process involves cleaning the port where the plug will be installed, applying the appropriate sealant if necessary, and screwing the plug into place using the correct tools. It is important to follow manufacturer guidelines to avoid over-tightening, which could damage the plug or the port.

Common Applications

The Cummins 3923960 Threaded Plug finds its use in various truck systems and components. It is commonly applied in engine blocks to seal off unused ports, in fuel systems to prevent leaks, and in hydraulic systems to maintain pressure integrity. Its versatility makes it a valuable component across different truck models and systems.

Troubleshooting and Maintenance

Identifying common issues with the Cummins 3923960 Threaded Plug, such as leaks or loose fittings, is important for maintaining system performance. Regular inspections and maintenance practices, including checking for signs of wear or damage and ensuring the plug is securely fitted, can help in preventing issues. Addressing problems promptly can extend the lifespan of the plug and maintain system efficiency.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of diesel engines, related technologies, and complete power solutions for commercial, industrial, and vehicle applications.

Threaded Plug 3923960 Compatibility with Cummins Engines

The Cummins Threaded Plug part number 3923960 is designed to fit seamlessly with a range of Cummins engines, ensuring reliable performance and maintenance. This part is integral to the engine’s operation, providing a secure seal for various applications.

6C8.3 Engine

The 6C8.3 engine benefits from the 3923960 Threaded Plug, which is crucial for maintaining the integrity of the engine’s cooling system. This plug ensures that coolant flows correctly, preventing leaks and maintaining optimal engine temperature.

ISC CM554 and ISL CM554 Engines

Both the ISC CM554 and ISL CM554 engines utilize the 3923960 Threaded Plug in their design. This plug is essential for the proper functioning of the engine’s lubrication system, ensuring that oil is contained within the engine and does not leak out. Its precision fit guarantees that the engine operates smoothly and efficiently.

QSC8.3 CM554 Engine

The QSC8.3 CM554 engine also incorporates the 3923960 Threaded Plug. This plug is vital for the engine’s fuel system, ensuring that fuel is contained and does not leak. Its design allows for easy installation and removal, making maintenance straightforward and reliable.

Grouping of Engines

The ISC CM554 and ISL CM554 engines share a similar design, which is why they both utilize the same threaded plug. This commonality simplifies maintenance and repair processes, as technicians can use the same part across multiple engine models. Similarly, the QSC8.3 CM554 engine, while distinct, also relies on the 3923960 Threaded Plug for its critical functions, ensuring that all engines in this family benefit from this reliable component.

Role of Part 3923960 Threaded Plug in Engine Systems

The 3923960 Threaded Plug is a component in various engine systems, ensuring the integrity and efficiency of these systems. Its primary function is to seal and secure connections, preventing leaks and maintaining system pressure.

Air Intake System

In the air intake system, the 3923960 Threaded Plug is used to seal connections between the air intake components. This ensures that the air entering the engine is clean and free from contaminants, which is vital for optimal engine performance and longevity. By maintaining a secure seal, the plug helps in preserving the air-fuel ratio, which is critical for efficient combustion.

Air Heater Starting System

The air heater starting system relies on the 3923960 Threaded Plug to seal connections in the air intake heater. This system is particularly important in cold climates, where preheating the intake air can significantly improve engine start-up and performance. The plug ensures that heated air is delivered efficiently to the engine, without any loss of heat or pressure.

Auxiliary Systems

Beyond the primary air intake and heating systems, the 3923960 Threaded Plug is also utilized in auxiliary systems where secure connections are necessary. These may include fuel lines, coolant systems, and other fluid transfer components. The plug’s role in these systems is to maintain the integrity of the connections, ensuring that fluids are transferred efficiently and without leaks.

Connection Integrity

Across all these systems, the 3923960 Threaded Plug plays a key role in maintaining connection integrity. Its threaded design allows for a tight seal, which is essential for systems that operate under high pressure or in environments where leaks can lead to significant issues. By ensuring that connections remain secure, the plug contributes to the overall reliability and performance of the engine systems.

Conclusion

The Cummins 3923960 Threaded Plug is a critical component in the maintenance and operation of commercial trucks. Its role in sealing and securing connections across various engine systems ensures the integrity and efficiency of these systems. Understanding its features, benefits, and proper installation process is essential for maintaining optimal truck performance and reliability.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.