This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

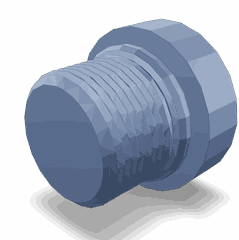

The Cummins 3923079 Threaded Plug is a component used in the maintenance and operation of commercial trucks. Cummins is renowned for producing reliable and high-quality parts. This Cummins part is significant in ensuring the integrity of various truck systems by sealing openings and preventing fluid leaks or the ingress of contaminants.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components designed to seal openings in various systems. They are commonly used in fluid systems, including hydraulic, fuel, and coolant systems, to maintain system pressure and prevent leaks. Threaded plugs function by being screwed into a threaded opening, creating a secure seal that prevents the escape of fluids or the entry of contaminants 1.

Purpose of the 3923079 Threaded Plug

The 3923079 Threaded Plug is specifically designed to seal openings in truck components, playing a role in maintaining system integrity. Its application includes sealing openings in fuel systems, coolant systems, and other fluid pathways to prevent leaks and protect the system from external contaminants. This ensures the efficient operation of the truck and extends the lifespan of the components it protects 2.

Key Features

The 3923079 Threaded Plug features a specific thread type and size tailored to fit the openings it is designed to seal. It is constructed from durable materials that can withstand the pressures and temperatures of the systems it serves. Additionally, the plug may have special coatings or treatments that enhance its resistance to corrosion and wear, contributing to its performance and durability 3.

Benefits

Using the 3923079 Threaded Plug offers several advantages. It contributes to improved system integrity by providing a reliable seal against fluid leaks. This reduces the need for frequent maintenance and repairs, leading to cost savings and increased operational efficiency. Furthermore, by preventing contaminants from entering the system, it enhances the safety and reliability of the truck’s operation 4.

Installation Process

Proper installation of the 3923079 Threaded Plug involves several steps to ensure a secure and effective seal. First, the opening must be clean and free of debris. The plug is then screwed into the opening using the appropriate tools to achieve the correct torque, ensuring a tight seal without over-tightening, which could damage the plug or the surrounding components.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks around the plug or difficulty in removal. Leaks may indicate that the plug is not properly seated or that there is damage to the plug or the threading. In such cases, re-evaluating the installation process or replacing the plug may be necessary. Difficulty in removal can often be addressed by using the correct tools and techniques to avoid damaging the plug or the component it is sealing.

Maintenance Tips

Regular inspection and maintenance of the 3923079 Threaded Plug are recommended to ensure ongoing performance and longevity. This includes checking for signs of wear or damage and ensuring that the plug remains securely in place. Replacement should be considered if there are signs of leakage or if the plug shows significant wear, to maintain system integrity and operational safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s extensive product range and commitment to reliability make it a preferred choice for truck manufacturers and operators, underscoring the quality and reliability of the 3923079 Threaded Plug.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of their engine models. It is integral for sealing and securing various components within the engine, ensuring optimal performance and preventing leaks.

ISB CM550 and QSB5.9 44 CM550

The ISB CM550 and QSB5.9 44 CM550 engines are both part of Cummins’ lineup of medium-duty diesel engines. The 3923079 threaded plug is compatible with these engines, providing a reliable seal for critical engine components. This ensures that the engines maintain their integrity and efficiency.

ISC CM554, QSC8.3 CM554, and QSL9 CM554

The ISC CM554, QSC8.3 CM554, and QSL9 CM554 engines are part of Cummins’ range of heavy-duty diesel engines. These engines are known for their robust performance and reliability in demanding applications. The 3923079 threaded plug fits seamlessly into these engines, providing a secure and leak-proof connection for various engine parts.

ISC CM850 and ISL CM554

The ISC CM850 and ISL CM554 engines are also part of Cummins’ heavy-duty diesel engine series. These engines are designed for high-performance applications, and the 3923079 threaded plug is engineered to meet the stringent requirements of these models. It ensures that all connections within the engine are tightly sealed, contributing to the overall reliability and efficiency of the engine.

ISL9 CM2150 SN

The ISL9 CM2150 SN engine is a high-output, heavy-duty diesel engine. The 3923079 threaded plug is compatible with this engine, providing a critical sealing function that is essential for maintaining the engine’s performance and longevity.

Role of 3923079 in Various Engine Systems

Plumbing Systems

In plumbing systems, the threaded plug serves as a vital component for sealing and regulating fluid flow. It is often used to cap off sections of piping that are not in use, ensuring that the system remains sealed and preventing any unwanted leakage. This is particularly important in complex plumbing networks where sections may be temporarily unused or under maintenance.

Crankcase Breather Systems

Within crankcase breather systems, the threaded plug plays a significant role in maintaining the integrity of the crankcase ventilation. It is used to seal off the breather passages when the system is not operational or during specific maintenance procedures. This ensures that the crankcase pressure remains balanced, which is essential for the efficient operation of the engine.

Vent Systems

In vent systems, the threaded plug is employed to seal off vent passages that may need to be temporarily closed. This is particularly useful in situations where the venting system requires maintenance or when specific operational conditions demand the sealing of certain vent paths. The plug ensures that the venting system operates efficiently without any unintended air leaks.

Engine Coolant Systems

For engine coolant systems, the threaded plug is utilized to seal off coolant passages that are not in use. This is important for maintaining the coolant system’s integrity, ensuring that coolant flows only through the intended pathways. It helps in preventing coolant loss and maintaining the system’s pressure, which is vital for the engine’s cooling efficiency.

Conclusion

The 3923079 Threaded Plug by Cummins is a critical component for maintaining the integrity and efficiency of various truck systems. Its role in sealing openings and preventing leaks contributes to the overall reliability and performance of commercial trucks. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engines are essential for maximizing the benefits of this part.

-

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

KTA19GC CM558/CM2358 Electronic Control System, Bulletin Number 4021661, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.