This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

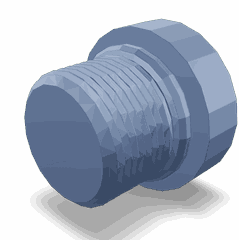

The Cummins 3907185 Threaded Plug is a specialized component designed for commercial trucks, contributing to the maintenance and operational efficiency of the vehicle. Understanding its purpose and role is essential for effective truck maintenance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive and industrial applications. They function by being screwed into place, creating a secure seal that prevents the escape of fluids or gases. These plugs are commonly utilized in engine blocks, transmission cases, and other systems where sealing is necessary to maintain system integrity and performance 1.

Purpose of the Cummins 3907185 Threaded Plug

The Cummins 3907185 Threaded Plug serves to seal specific openings within a truck’s engine or other systems. Its function is to prevent the leakage of fluids or gases, ensuring that the system operates efficiently and without contamination. By maintaining a secure seal, it contributes to the overall performance and longevity of the truck’s engine and related systems 4.

Key Features

The Cummins 3907185 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the pressures and temperatures within the engine system, and its thread type, which ensures a tight and secure fit. The design specifications of the plug are tailored to meet the demands of commercial truck applications, providing reliability and efficiency 2.

Benefits

Utilizing the Cummins 3907185 Threaded Plug offers several advantages. It contributes to improved system integrity by ensuring a secure seal, which prevents fluid leaks and maintains system pressure. This, in turn, enhances overall engine performance and efficiency. Additionally, the plug’s durable construction and precise design help to extend the lifespan of the truck’s engine and related systems 3.

Installation Process

Installing the Cummins 3907185 Threaded Plug requires careful attention to detail to ensure a secure fit. The process involves cleaning the installation site, applying the appropriate sealant if necessary, and screwing the plug into place using the correct tools. It is important to follow best practices to avoid over-tightening, which can damage the plug or the surrounding components, and to ensure that the plug is properly seated to achieve an effective seal 4.

Troubleshooting Common Issues

Common issues associated with threaded plugs include leaks or improper sealing. These problems can often be traced to incorrect installation, damage to the plug or its seating surface, or degradation of the plug over time. Troubleshooting steps may involve re-examining the installation process, inspecting the plug and its seating surface for damage, and replacing the plug if necessary to restore a secure seal 1.

Maintenance Tips

Regular maintenance checks are recommended to ensure the longevity and proper function of the Cummins 3907185 Threaded Plug. This includes inspecting the plug for signs of wear or damage, ensuring that it remains securely in place, and addressing any issues promptly to prevent system leaks or performance degradation. Following manufacturer guidelines for maintenance intervals and procedures can help to maximize the plug’s effectiveness and lifespan 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications 3.

Compatibility with Cummins Engines

The Threaded Plug 3907185, manufactured by Cummins, is designed to fit seamlessly into various Cummins engine models. This plug is integral for ensuring the integrity and functionality of the engine’s systems.

Compatibility with Specific Engine Models

- 4B3.9 Engine: The 3907185 threaded plug is specifically engineered to fit the 4B3.9 engine. It is used in areas where a secure and leak-proof connection is essential, often in fuel lines or coolant passages.

- 6B5.9 Engine: Similarly, the 3907185 threaded plug is also compatible with the 6B5.9 engine. This plug ensures that the engine’s components are properly sealed, preventing any fluid leaks and maintaining optimal engine performance.

Grouping for Ease of Use

For ease of use and inventory management, the 3907185 threaded plug is grouped under the following categories:

- Cummins Engine Accessories: This grouping helps technicians and mechanics quickly identify the plug as a necessary part for Cummins engines.

- Fuel System Components: Given its frequent use in fuel lines, the plug is also categorized under fuel system components, aiding in the identification and procurement of parts for fuel system maintenance.

Application and Installation

When installing the 3907185 threaded plug, it is crucial to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes using the correct torque specifications and ensuring that the threads are clean and free of debris. Proper installation is vital for maintaining the engine’s performance and longevity 2.

Importance of Correct Part Usage

Using the correct threaded plug for each engine model is essential. The 3907185 plug is designed with precision to fit the specific requirements of the 4B3.9 and 6B5.9 engines, ensuring compatibility and reliability. Incorrect part usage can lead to system failures and potential engine damage 3.

Role of Part 3907185 Threaded Plug in Engine Systems

The part 3907185 Threaded Plug ensures the integrity and efficiency of various engine systems by sealing and securing connections. Its application spans across multiple components, contributing to the overall performance and reliability of the engine.

Air Intake System

In the air intake system, the Threaded Plug is utilized to seal connections between the air intake and the intake manifold. This ensures that the air entering the engine is clean and free from contaminants, which is essential for optimal combustion. The plug also helps maintain the correct air-fuel ratio by preventing air leaks, which can lead to inefficient engine performance 1.

Turbocharger System

Within the turbocharger system, the Threaded Plug is employed at the turbocharger mounting and turbocharger location to secure and seal connections. This is important for maintaining the turbocharger’s efficiency and durability. By ensuring a tight seal, the plug helps prevent oil leaks and maintains the proper pressure within the turbocharger, contributing to enhanced engine performance and longevity 4.

Upper Engine Gasket Sets

The Threaded Plug plays a significant role in the upper engine gasket sets, including the .15mm and .50mm sets. It is used to seal the connections between the upper engine components, such as the cover and the intake manifold. This sealing is vital for maintaining the integrity of the engine’s upper section, preventing coolant or oil leaks, and ensuring that the engine operates within its designed parameters 2.

Air Heater Starting System

In the air heater starting system, the Threaded Plug is used to seal the air heater starting aid and the air intake connection. This ensures that the heated air is effectively delivered to the intake manifold, aiding in easier engine starts in cold conditions. The plug’s sealing properties are essential for the efficient operation of the air heater system, contributing to better engine performance during startup 3.

Turbocharger Arrangement

The Threaded Plug is also integral in the turbocharger arrangement, where it seals the connections at various points within the turbocharger setup. This includes sealing the connections at the turbocharger location and the turbocharger mounting. By ensuring these seals are intact, the plug helps maintain the turbocharger’s efficiency, preventing performance issues that could arise from leaks or loose connections 4.

Conclusion

The Cummins 3907185 Threaded Plug is a versatile component that enhances the functionality and reliability of various engine systems by providing essential sealing and securing capabilities. Proper installation, maintenance, and the use of the correct part are crucial for ensuring the optimal performance and longevity of commercial truck engines.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ ↩ ↩ -

Hu, Haoran, Rudy Smaling, Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ ↩ ↩ ↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.