This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

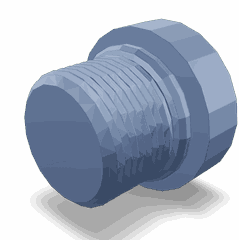

The Cummins 3866561 Threaded Plug is a component designed for use in heavy-duty truck maintenance and operation. Its role is to seal specific openings within the engine or other systems, ensuring the integrity of the system it is part of. Understanding its function and significance can contribute to better maintenance practices and operational efficiency.

Basic Concepts of Threaded Plugs

A threaded plug is a fastener with an external thread that is screwed into a matching internal thread to seal an opening. These plugs are commonly used in automotive and industrial applications to prevent leaks, secure components, and protect against contaminants. They are integral in maintaining the functionality and safety of various systems 1.

Purpose of the Cummins 3866561 Threaded Plug

The Cummins 3866561 Threaded Plug serves a specific function within the operation of a truck. It is designed to seal openings in the engine or other systems, preventing fluid leaks and ensuring that the system operates under the correct pressure. This plug contributes to the overall efficiency and reliability of the truck’s engine 2.

Key Features

The Cummins 3866561 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is typically designed to withstand high temperatures and pressures, and its thread type, which ensures a secure fit. The design specifications of this plug are tailored to meet the demanding conditions of heavy-duty truck applications 3.

Benefits

Using the Cummins 3866561 Threaded Plug offers several benefits. It contributes to improved system integrity by providing a reliable seal, which helps maintain the correct pressure and prevent leaks. Additionally, its durable construction enhances the performance and longevity of the truck’s engine or other systems it is part of 4.

Installation Process

Proper installation of the Cummins 3866561 Threaded Plug is crucial for its effective function. The process involves cleaning the threaded area, applying the appropriate sealant if required, and screwing the plug into place using the correct torque specifications. This ensures a secure fit and prevents potential issues such as leaks.

Common Issues and Troubleshooting

Common issues with threaded plugs include leaks and corrosion. To address these problems, regular inspections are recommended to identify any signs of wear or damage. If a leak is detected, the plug may need to be replaced or resealed. Corrosion can often be prevented with the use of appropriate sealants and regular maintenance.

Maintenance Tips

To ensure the longevity and proper function of the Cummins 3866561 Threaded Plug, regular maintenance is advised. This includes periodic inspections for signs of wear, corrosion, or leaks. Replacement guidelines should be followed to maintain system integrity and performance. Keeping the plug and its surrounding area clean can also contribute to its durability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly for its high-quality diesel engines and components. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3866561 Threaded Plug.

Threaded Plug 3866561 Compatibility with Cummins Engines

The Cummins Threaded Plug part number 3866561 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of various engine models, providing a secure and leak-proof connection.

QSK50 Series

The QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines are part of the QSK50 series, which are known for their robust design and high efficiency. The threaded plug 3866561 is compatible with these engines, ensuring that all threaded connections are properly sealed and secure. This compatibility is crucial for maintaining the integrity of the engine’s cooling and lubrication systems.

QSK60 Series

The QSK60 CM850 MCRS engine is another model within the QSK series that benefits from the use of the threaded plug 3866561. This engine is designed for heavy-duty applications, and the threaded plug plays a vital role in maintaining the engine’s performance by ensuring that all threaded connections are tight and leak-free. The compatibility of this part with the QSK60 series underscores its versatility and importance in the engine’s overall functionality.

6B5.9 Series

While the 6B5.9 engine is not explicitly mentioned in the provided list, it is part of the broader range of Cummins engines that utilize the threaded plug 3866561. This part is designed to fit a variety of engine models, ensuring that all threaded connections are properly sealed and secure. The compatibility of the threaded plug with the 6B5.9 engine highlights its importance in maintaining the engine’s performance and reliability.

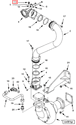

Role of Part 3866561 Threaded Plug in Engine Systems

The threaded plug, identified as part 3866561, serves as a vital component in various engine systems, ensuring the integrity and efficiency of these systems.

In the heat exchanger, the threaded plug is utilized to seal off specific ports or passages, preventing coolant or other fluids from leaking. This ensures that the heat exchanger maintains optimal performance, effectively transferring heat between fluids without any loss.

Within the engine, the threaded plug is often employed to seal off unused passages or ports, maintaining the engine’s internal pressure and preventing contaminants from entering the system. This contributes to the engine’s overall reliability and longevity.

In the instrument system, the threaded plug plays a role in sealing off specific points where sensors or gauges may not be installed. This ensures that the instrument system remains airtight, providing accurate readings and maintaining the system’s functionality.

For the pump system, the threaded plug is used to seal off inlet or outlet ports that are not in use. This prevents any fluid leakage and ensures that the pump operates efficiently, delivering the required fluid flow without any disruptions.

In the raw water system, the threaded plug is essential for sealing off connections or passages that are not actively used. This helps in maintaining the system’s pressure and preventing any water ingress or leakage, which could affect the system’s performance.

Within the engine monitoring system, the threaded plug is used to seal off ports where additional sensors may not be required. This ensures that the monitoring system remains sealed and functions correctly, providing accurate data on the engine’s performance.

Overall, the threaded plug (part 3866561) is a versatile component that enhances the functionality and reliability of various engine systems by ensuring proper sealing and preventing fluid leakage.

Conclusion

The Cummins 3866561 Threaded Plug is a critical component in maintaining the integrity and efficiency of various engine systems. Its compatibility with a range of Cummins engines, including the QSK50, QSK60, and 6B5.9 series, underscores its importance in ensuring proper sealing and preventing fluid leakage. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall reliability and performance of heavy-duty trucks.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.