This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

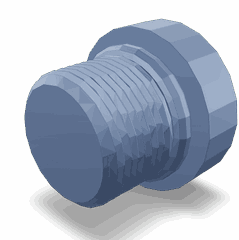

The Cummins 3638718 Threaded Plug is a component designed for use in commercial truck maintenance. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining the performance of commercial trucks.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive and industrial applications. They function by creating a secure, leak-proof seal when screwed into place. These plugs are commonly used to block off passages, prevent fluid leaks, and maintain system integrity. In automotive settings, threaded plugs are vital for engine and transmission systems, ensuring that fluids remain contained and systems operate efficiently 1.

Purpose of the Cummins 3638718 Threaded Plug

The Cummins 3638718 Threaded Plug plays a role in the operation and maintenance of commercial trucks by sealing specific openings within the engine. This plug is designed to prevent fluid leaks and maintain system pressure, contributing to the engine’s overall performance and longevity. Its application is crucial in ensuring that the engine operates within optimal parameters, reducing the risk of damage from fluid loss or contamination 2.

Key Features

The Cummins 3638718 Threaded Plug is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a specific thread type that allows for a secure fit within the engine’s openings. Its design specifications are tailored to meet the demanding requirements of commercial truck engines, providing a reliable sealing solution 3.

Benefits

Utilizing the Cummins 3638718 Threaded Plug offers several advantages. Its design contributes to improved sealing, reducing the likelihood of fluid leaks. The plug’s durable construction ensures longevity, even under the harsh conditions typical of commercial truck operations. Additionally, the plug is designed for ease of installation, allowing for quick and efficient maintenance procedures 4.

Common Applications

The Cummins 3638718 Threaded Plug is typically used in various applications within a truck’s engine and other systems. It is commonly installed in engine blocks, transmission cases, and other components where sealing is required. Its versatility makes it a valuable component for maintaining the integrity of the truck’s fluid systems 5.

Installation Process

Installing the Cummins 3638718 Threaded Plug involves several steps to ensure a proper fit and seal. Begin by cleaning the installation site to remove any debris or old sealant. Apply a compatible thread sealant to the plug’s threads to enhance the seal. Carefully screw the plug into place, using a torque wrench to achieve the manufacturer’s recommended torque specification. This ensures a secure fit without over-tightening, which could damage the plug or the engine component 6.

Troubleshooting and Maintenance

Identifying common issues with threaded plugs, such as leaks or difficulty in removal, is important for maintaining engine performance. Regular inspection and maintenance can help prevent problems. If a plug shows signs of wear or damage, it should be replaced to maintain system integrity. Following the manufacturer’s guidelines for maintenance and replacement intervals ensures the plug continues to perform effectively 7.

Safety Considerations

When installing or maintaining the Cummins 3638718 Threaded Plug, it is important to follow safety practices to prevent injuries or damage. Ensure the engine is cool before beginning work to avoid burns. Use the appropriate tools and follow torque specifications to prevent damage to the plug or engine component. Wearing protective gear, such as gloves and safety glasses, is recommended to protect against injuries 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 9.

Threaded Plug 3638718 Compatibility with Cummins Engines

The Threaded Plug 3638718, manufactured by Cummins, is designed to fit a variety of Cummins engines. This plug is a critical component in ensuring the integrity and functionality of the engine’s systems. Below is a detailed description of its compatibility with the listed engines:

K50 Series Engines

- K50

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The K50 series engines, including the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108, are designed for high-performance applications. The Threaded Plug 3638718 is engineered to fit seamlessly into these engines, providing a secure and reliable connection for various fluid lines and sensors.

KTA38 Series Engines

- KTA38GC CM558

The KTA38GC CM558 engine is another variant that benefits from the Threaded Plug 3638718. This plug ensures that all necessary fluid lines and sensors are properly sealed and connected, maintaining the engine’s operational efficiency.

QSK38 Series Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, including the QSK38 CM2150 MCRS and QSK38 CM850 MCRS, are known for their robust design and reliability. The Threaded Plug 3638718 is compatible with these engines, ensuring that all connections are secure and leak-proof.

QSK60 Series Engines

- QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine is designed for heavy-duty applications. The Threaded Plug 3638718 fits this engine perfectly, providing a reliable seal for critical connections.

QSK95 Series Engines

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK95 series engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113, are built for maximum power and efficiency. The Threaded Plug 3638718 is an essential component for these engines, ensuring that all connections are secure and reliable.

By ensuring that the Threaded Plug 3638718 fits all these engines, Cummins maintains a high standard of quality and reliability across its engine lineup. This compatibility is crucial for maintaining the performance and longevity of the engines in various applications.

Role of Part 3638718 Threaded Plug in Engine Systems

The part 3638718 threaded plug is an essential component in various engine systems, ensuring the integrity and efficiency of several key components.

In the context of base parts, the threaded plug is often utilized to seal off unused passages or ports. This prevents coolant or oil leaks, maintaining the system’s pressure and ensuring that fluids remain within their designated pathways. By effectively sealing these passages, the plug contributes to the overall reliability and performance of the engine.

When integrated with the water pump, the threaded plug plays a significant role in maintaining the pump’s structural integrity. Water pumps in engine systems are responsible for circulating coolant throughout the engine to regulate temperature. The plug helps to seal any non-functional ports on the water pump housing, preventing coolant loss and ensuring that the pump operates efficiently. This sealing function is vital for the consistent performance of the cooling system.

In a water pump kit, which typically includes the water pump along with gaskets, seals, and other necessary components, the threaded plug is often included to address any potential leaks from the water pump housing. Its role in this kit is to provide a comprehensive solution for maintaining the water pump’s sealing integrity, thereby enhancing the kit’s effectiveness in ensuring a leak-free cooling system.

Overall, the threaded plug 3638718 is a versatile component that enhances the functionality and reliability of engine systems by providing essential sealing capabilities across various applications.

Conclusion

The Cummins 3638718 Threaded Plug is a critical component in the maintenance and operation of commercial truck engines. Its role in sealing openings, preventing fluid leaks, and maintaining system pressure is essential for the engine’s performance and longevity. The plug’s durable construction, ease of installation, and compatibility with various Cummins engines make it a valuable asset for maintaining the integrity of commercial truck fluid systems. Regular maintenance and adherence to safety practices ensure that the plug continues to perform effectively, contributing to the overall reliability and efficiency of the vehicle.

-

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4332748, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4332748, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4332748, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4332748, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4332748, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.