This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

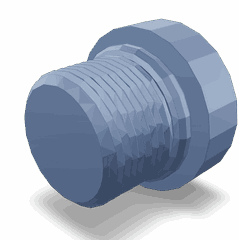

The Threaded Plug Assembly 3633039 is a component designed by Cummins for use in heavy-duty trucks. It serves a specific function within the truck’s systems, contributing to the overall maintenance and operational efficiency of the vehicle. Understanding its purpose and significance is key to maintaining the integrity and performance of heavy-duty trucks.

Basic Concepts of Threaded Plug Assemblies

A threaded plug assembly is a mechanical component used to seal openings in various systems within a vehicle. It consists of a plug with threads that screw into a corresponding threaded opening, creating a secure seal. These assemblies are utilized in automotive engineering to prevent leaks, secure components, and maintain system pressure. They are commonly found in engine blocks, transmission cases, and other critical areas where sealing is necessary 1.

Purpose of the 3633039 Threaded Plug Assembly

The 3633039 Threaded Plug Assembly is designed to seal specific openings within a truck’s engine or other systems. Its role is to ensure that fluids, gases, or other materials do not escape from the system, maintaining the system’s integrity and efficiency. By providing a reliable seal, it contributes to the overall performance and longevity of the truck 2.

Key Features

The 3633039 Threaded Plug Assembly is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear. The threading specifications are designed to ensure a tight and secure fit within the designated openings. Additionally, the assembly may include unique design aspects such as gaskets or seals to improve its sealing capabilities 3.

Benefits of Using the 3633039 Threaded Plug Assembly

Incorporating the 3633039 Threaded Plug Assembly into truck maintenance routines offers several advantages. It improves system integrity by providing a reliable seal, enhances performance by preventing leaks, and contributes to the longevity of the truck by reducing the risk of system failure due to leaks or pressure loss.

Installation and Usage Guidelines

Proper installation of the 3633039 Threaded Plug Assembly involves several steps to ensure optimal performance and longevity. Preparatory steps include cleaning the threaded opening and inspecting the assembly for any damage. The necessary tools for installation may include a torque wrench to ensure the plug is tightened to the manufacturer’s specifications. Best practices include applying a thread sealant to enhance the seal and avoiding over-tightening to prevent damage to the threads.

Troubleshooting Common Issues

Frequent problems associated with threaded plug assemblies can include leaks, difficulty in removal, or damage to the threads. Potential causes may be improper installation, wear and tear, or corrosion. Recommended troubleshooting steps include inspecting the assembly for signs of wear or damage, ensuring the threads are clean and undamaged, and reapplying thread sealant if necessary.

Maintenance Tips

Routine maintenance practices for the 3633039 Threaded Plug Assembly are crucial for ensuring continued reliable operation. Inspection intervals should be established based on the truck’s usage and operating conditions. Cleaning procedures may involve removing the assembly and cleaning the threads and surrounding area. Replacement should be considered if signs of wear, corrosion, or damage are observed.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the automotive and heavy-duty truck industry. The 3633039 Threaded Plug Assembly, as a product of Cummins, benefits from the company’s commitment to excellence and innovation in automotive engineering.

Compatibility with Cummins Engines

This part is designed to fit a variety of Cummins engines. Below is a detailed description of its compatibility with the specified engines:

K38 and QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

This part ensures proper sealing and secure connections in these engines, maintaining system integrity and performance.

K50 and QSK50 Series

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK50 CM2150 K107

This part is crucial for ensuring that threaded connections are properly sealed and secured, contributing to the overall reliability and efficiency of these engines.

K114 Series

- QSK19 CM2350 K114

This part is essential for maintaining the integrity of threaded connections within the engine, ensuring that the system operates smoothly and efficiently.

QSK19 Series

- QSK19 CM850 MCRS

This part plays a vital role in sealing and securing threaded connections, which is critical for the engine’s performance and longevity.

By ensuring that the Threaded Plug Assembly 3633039 is correctly installed, engine operators can maintain the reliability and efficiency of their Cummins engines. This part is a key component in the engine’s sealing and connection system, providing a secure fit that is essential for optimal engine performance.

Role of the 3633039 Threaded Plug Assembly in Engine Systems

The 3633039 Threaded Plug Assembly is an essential component in the maintenance and operation of various engine systems. It is specifically designed to interface with several key components to ensure the efficient and reliable performance of the engine.

Integration with Filters

In engine systems, the Threaded Plug Assembly is often used in conjunction with filters. When a filter, such as a lubricating oil filter, needs to be replaced or serviced, the Threaded Plug Assembly provides a secure and leak-proof seal. This ensures that the lubricating oil remains contained within the system, preventing any potential contamination or loss of oil. The assembly’s threaded design allows for easy installation and removal, facilitating routine maintenance procedures.

Lubricating Oil Systems

The Threaded Plug Assembly plays a significant role in lubricating oil systems. It is commonly used to seal off ports or openings in the oil filter head, ensuring that the lubricating oil circulates properly throughout the engine. This is vital for maintaining the correct oil pressure and ensuring that all moving parts are adequately lubricated, which reduces wear and tear and enhances engine longevity.

Filter Kits

When dealing with filter kits, which often include multiple filters and associated components, the Threaded Plug Assembly is used to seal any unused ports or openings. This is particularly important in modular engine systems where different configurations may require the use of various filters. The assembly ensures that the integrity of the lubricating oil system is maintained, regardless of the specific filter configuration in use.

Lubricating Oil Filter Head

The lubricating oil filter head is a critical component in the oil filtration system, and the Threaded Plug Assembly is often used to seal off any bypass or relief ports. This ensures that the oil flows through the filter media as intended, maximizing the efficiency of the filtration process. The secure seal provided by the assembly prevents any unfiltered oil from bypassing the filter, which could lead to increased contamination and reduced engine performance.

Conclusion

In summary, the 3633039 Threaded Plug Assembly is a versatile and reliable component that enhances the functionality and maintenance of engine systems by ensuring secure and leak-proof seals in various applications involving filters and lubricating oil systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.