This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3421077 Threaded Plug is a critical component in commercial truck maintenance, designed to ensure the integrity and efficiency of various truck systems. Understanding its purpose and role is essential for maintaining vehicle performance and longevity.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in automotive systems. They prevent fluid leaks and protect internal components from external contaminants. These plugs are used in engine blocks, transmission systems, and hydraulic circuits to maintain system pressure and prevent fluid escape 1.

Purpose of the Cummins 3421077 Threaded Plug

This Cummins part is designed to fit into designated ports within a truck’s engine or other systems. Its primary function is to seal these ports, preventing the leakage of fluids such as oil, coolant, or fuel. By maintaining a secure seal, the plug contributes to the overall efficiency and reliability of the truck’s operation 2.

Key Features

The 3421077 Threaded Plug is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features a precise thread type that allows for a tight fit within the port, minimizing the risk of leaks. The design specifications of the plug are tailored to withstand the pressures and temperatures encountered in commercial truck applications 3.

Benefits

Utilizing the Cummins 3421077 Threaded Plug offers several advantages. It enhances system integrity by providing a reliable seal, which is crucial for maintaining fluid levels and pressure. The plug also helps in preventing fluid leaks, which can lead to engine damage and decreased performance. Additionally, by ensuring a secure seal, the plug contributes to the overall efficiency of the engine, promoting smoother operation and potentially extending the lifespan of the vehicle.

Installation Process

Installing the Cummins 3421077 Threaded Plug requires careful attention to detail. The process involves cleaning the port to remove any debris, applying a thread sealant if necessary, and screwing the plug into place using the appropriate tools. It is important to achieve the correct torque specification to ensure a secure fit without over-tightening, which could damage the plug or the port.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and corrosion. If a leak is detected, the plug should be inspected for proper seating and condition. Corrosion can be addressed by cleaning the plug and port thoroughly before reinstallation. Regular inspections can help identify and resolve these issues promptly, maintaining the plug’s effectiveness.

Maintenance Tips

To prolong the lifespan of the Cummins 3421077 Threaded Plug, regular maintenance checks are recommended. This includes inspecting the plug for signs of wear or damage, ensuring it remains securely in place, and cleaning the port to prevent the buildup of contaminants. Adhering to these practices can help maintain the plug’s performance and contribute to the overall reliability of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Their product range is designed to meet the demanding requirements of commercial applications, ensuring performance, efficiency, and durability.

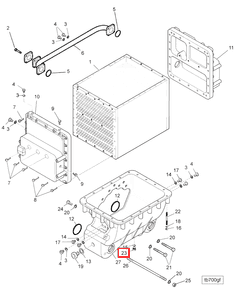

Threaded Plug Part 3421077 Compatibility with Cummins Engines

The Threaded Plug part number 3421077, manufactured by Cummins, is designed to fit seamlessly into various engine models. This part is integral to the functionality of the engines, ensuring proper sealing and operational integrity.

QSW/QSV82 Engines

In the QSW/QSV82 engines, the Threaded Plug part 3421077 is utilized in several critical areas. Its precision-engineered design ensures that it fits snugly, providing a reliable seal that prevents leaks and maintains the internal pressure required for optimal engine performance.

QSW73 Engines

Similarly, for the QSW73 engines, the Threaded Plug part 3421077 is an essential component. It is engineered to meet the specific requirements of these engines, ensuring that it integrates smoothly and functions effectively within the engine’s design.

Grouping of Engines

Both the QSW/QSV82 and QSW73 engines benefit from the use of the Threaded Plug part 3421077. While each engine model may have unique specifications, the threaded plug’s compatibility across these engines highlights its versatility and importance in maintaining engine efficiency and reliability.

Role of Part 3421077 Threaded Plug in Engine Systems

The part 3421077 Threaded Plug is an essential component in various engine systems, contributing to their efficient operation and performance. Here’s how it integrates with different components:

Air Intake Assembly

In the air intake assembly, the threaded plug helps seal connections, ensuring that air enters the engine cleanly and without leaks. This is vital for maintaining the correct air-fuel ratio, which is necessary for optimal combustion.

Air Intake Manifold and Manifold Air Intake Assembly

When installed in the air intake manifold or manifold air intake assembly, the threaded plug secures fittings and connections. This prevents air leaks that could disrupt the airflow into the engine, thereby affecting performance and fuel efficiency.

Air Outlet Assembly Pipe and Air Outlet Pipe

In the air outlet assembly pipe and air outlet pipe, the threaded plug ensures that the exhaust gases are directed away from the engine compartment efficiently. It helps maintain the integrity of the exhaust system by sealing joints and connections.

Turbocharger and Turbocharger Arrangement

Within the turbocharger and its arrangement, the threaded plug plays a role in sealing oil lines and other critical connections. This is important for maintaining the turbocharger’s lubrication and cooling systems, which are essential for its longevity and performance.

Charge Air Assembly Cooler and Cooler Charge Air S/Assembly

In the charge air assembly cooler and cooler charge air s/assembly, the threaded plug ensures that the charge air is cooled effectively without any leaks. This is important for maintaining the efficiency of the intercooling process, which directly impacts engine power and efficiency.

Intake Assembly Manifold and Manifold Intake Assembly

For the intake assembly manifold and manifold intake assembly, the threaded plug secures various connections, ensuring that the intake process is smooth and free from leaks. This contributes to better engine performance and fuel economy.

Conclusion

In summary, the Cummins 3421077 Threaded Plug is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure and leak-free connections. Regular maintenance and proper installation are key to maximizing its benefits and ensuring the longevity and efficiency of the vehicle.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.