This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

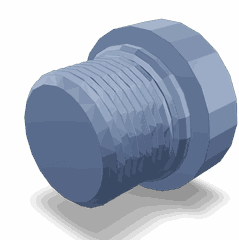

The Cummins 3412405 Threaded Plug is a component designed for use in commercial trucks. It serves a specific function in maintaining the integrity of various systems within these vehicles. Understanding its purpose and role is fundamental for effective truck maintenance and ensuring optimal performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in automotive systems. They consist of a threaded section that screws into a corresponding threaded hole, creating a secure seal. These plugs are utilized in various applications, including engine blocks, transmission cases, and other fluid systems, to prevent leaks and maintain system pressure 1.

Purpose of the Cummins 3412405 Threaded Plug

The Cummins 3412405 Threaded Plug plays a role in sealing specific ports within a truck’s engine or other systems. Its function is to prevent fluid leaks and maintain system integrity. By securely fitting into designated openings, it ensures that fluids remain contained within their intended pathways, contributing to the overall efficiency and reliability of the truck’s operation.

Key Features

The Cummins 3412405 Threaded Plug is engineered with several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear. The plug features a precise thread type that ensures a tight fit, and its design specifications are tailored to withstand the demanding conditions encountered in commercial truck applications.

Benefits of Using the 3412405 Threaded Plug

Utilizing the Cummins 3412405 Threaded Plug offers several advantages. Its design contributes to improved sealing, which is vital for maintaining system pressure and preventing leaks. The plug’s resistance to corrosion ensures longevity, even in harsh operating environments. Additionally, its durable construction supports consistent performance over time, reducing the need for frequent replacements 2.

Installation Process

Proper installation of the Cummins 3412405 Threaded Plug is crucial for ensuring optimal performance and safety. The process involves cleaning the threaded hole to remove any debris, applying a compatible thread sealant to enhance the seal, and carefully screwing the plug into place until it reaches the specified torque. Following these steps helps to achieve a secure fit and maintain the integrity of the system.

Common Issues and Troubleshooting

Threaded plugs, including the Cummins 3412405, may encounter issues such as leaks or damage over time. Common problems can often be traced to improper installation, wear and tear, or corrosion. Troubleshooting these issues may involve inspecting the plug for signs of damage, ensuring the threads are clean and undamaged, and reapplying thread sealant if necessary. In some cases, replacement of the plug may be required to restore system integrity 3.

Maintenance Tips

Regular maintenance is key to prolonging the life of the Cummins 3412405 Threaded Plug. This includes periodic inspection for signs of wear or corrosion, ensuring that the plug remains securely in place, and addressing any leaks promptly. Adhering to recommended inspection schedules and care instructions can help maintain the plug’s performance and contribute to the overall reliability of the truck.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the field.

Threaded Plug 3412405 Compatibility with Cummins Engines

The Threaded Plug 3412405, manufactured by Cummins, is a crucial component designed to fit seamlessly with several of their engine models. This plug is integral to the engine’s operation, ensuring that various systems function correctly by providing a secure seal.

G855

The G855 engine benefits from the Threaded Plug 3412405, which is specifically engineered to fit its design. This plug is essential for maintaining the integrity of the engine’s internal systems, ensuring that there are no leaks or malfunctions.

N14 CELECT PLUS and N14 MECHANICAL

Both the N14 CELECT PLUS and N14 MECHANICAL engines utilize the Threaded Plug 3412405. This plug is designed to fit the unique specifications of these engines, providing a reliable seal that is critical for the engines’ performance. Its compatibility with these models ensures that the engines can operate efficiently and safely.

QSN14 CM876 N103

The QSN14 CM876 N103 engine also incorporates the Threaded Plug 3412405. This plug is tailored to fit the specific requirements of this engine model, ensuring that it can maintain its operational integrity and performance standards. Its design allows for a precise fit, which is essential for the engine’s overall functionality.

Role of Part 3412405 Threaded Plug in Engine Systems

In the realm of engine systems, the threaded plug, specifically part 3412405, serves a significant function in maintaining the integrity and efficiency of various components. This component is integral in systems involving the circulation and cooling of engine oil, ensuring optimal performance and longevity of the engine.

Integration with Oil Coolers

The threaded plug is often utilized in oil cooler systems, including the engine oil cooler and the lubricating oil cooler. Its role here is to seal off specific points within the cooler, preventing leaks and ensuring that the oil circulates efficiently through the cooling passages. This is particularly important in the top-level assembly coolers, where the oil is cooled before being recirculated back into the engine. The efficient sealing provided by the threaded plug helps maintain the pressure within the cooler, which is essential for the effective transfer of heat away from the oil.

Function in Lubricating Oil Systems

In lubricating oil systems, the threaded plug is employed in both the top-level assembly cooler and the standard lubricating oil cooler. Its application in these systems is to seal off ports that are not in use, ensuring that the lubricating oil does not escape and that contaminants do not enter the system. This is vital for maintaining the purity and viscosity of the lubricating oil, which directly impacts the engine’s friction levels and overall efficiency.

Role in Oil (Top Level Assembly) Cooler

Specifically, in the oil (top level assembly) cooler, the threaded plug plays a key role in managing the flow of oil. By sealing off certain pathways, it directs the oil through the most efficient cooling routes, enhancing the cooler’s effectiveness. This is particularly beneficial in high-performance engines where maintaining the oil at an optimal temperature is essential for performance and reliability.

Application in Complex Cooling Systems

In more complex cooling systems, such as those involving multiple stages of cooling or integrated cooling for both engine oil and lubricating oil, the threaded plug is used to compartmentalize the cooling process. This allows for more precise control over the cooling of different types of oil, ensuring that each type is maintained at its ideal temperature for maximum engine efficiency.

Conclusion

In summary, the Cummins 3412405 Threaded Plug is a versatile component in engine systems, particularly within oil cooling and lubrication circuits. Its ability to seal and direct the flow of oil is fundamental to the efficient operation and longevity of engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.