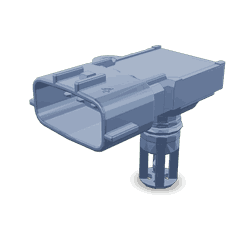

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4921324 Pressure Temperature Sensor is designed to monitor and report the pressure and temperature conditions within a truck’s engine system. This part ensures the engine operates within optimal parameters, contributing to efficient performance and longevity of the vehicle 4.

Basic Concepts of Pressure Temperature Sensors

Pressure temperature sensors measure the pressure and temperature of fluids or gases within a system. They convert physical parameters into electrical signals, which are interpreted by the vehicle’s engine management system. These sensors are crucial in automotive systems to ensure components operate under the correct conditions, enhancing performance and safety 1.

Role of the 4921324 Pressure Temperature Sensor in Truck Operation

The Cummins 4921324 Pressure Temperature Sensor is integrated into the engine management system of commercial trucks. It provides real-time data on the pressure and temperature of the engine’s fluids, allowing the system to make adjustments for optimal performance. This sensor ensures that the engine operates efficiently by providing accurate readings that help in fuel management, emission control, and overall engine health 2.

Key Features of the 4921324 Pressure Temperature Sensor

The Cummins 4921324 Pressure Temperature Sensor is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in harsh operating conditions. Technological advancements incorporated into this sensor enhance its accuracy and responsiveness, contributing to its performance and reliability in demanding truck applications 3.

Benefits of Using the 4921324 Pressure Temperature Sensor

Incorporating the Cummins 4921324 Pressure Temperature Sensor into truck systems offers several advantages. It contributes to improved engine efficiency by ensuring optimal operating conditions. Additionally, it enhances diagnostic capabilities, allowing for early detection of potential issues. This sensor also plays a role in maintaining overall vehicle performance by providing accurate data for the engine management system 4.

Installation and Integration

Proper installation of the Cummins 4921324 Pressure Temperature Sensor is crucial for its effective operation. It should be integrated into the truck’s engine system according to manufacturer guidelines, ensuring secure placement and correct electrical connections. Precautions should be taken to protect the sensor from physical damage and ensure it is correctly aligned within the system 2.

Troubleshooting Common Issues

Common problems associated with pressure temperature sensors include inaccurate readings and sensor failure. These issues can arise from physical damage, electrical faults, or exposure to extreme conditions. Troubleshooting steps may involve checking electrical connections, inspecting the sensor for physical damage, and ensuring it is correctly installed within the system 1.

Maintenance Tips

Regular maintenance of the Cummins 4921324 Pressure Temperature Sensor is important for its optimal functioning. This includes cleaning the sensor to remove any contaminants, calibrating it to ensure accurate readings, and conducting routine inspections for signs of wear or damage. Adhering to these maintenance practices helps in prolonging the sensor’s lifespan and ensuring reliable operation 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company is committed to advancing technology and sustainability in the automotive industry, providing reliable and efficient solutions for its customers 4.

Compatibility with Cummins Engines

The Pressure Temperature Sensor 4921324, manufactured by Cummins, is designed to be compatible with a wide range of Cummins engines. This sensor plays a role in monitoring and maintaining the engine’s performance by providing data on pressure and temperature. Below is a detailed overview of the engines with which this sensor is compatible.

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

The ISC series engines, including the ISC CM2150 and ISC8.3 CM2250, benefit from the Pressure Temperature Sensor 4921324. This sensor ensures optimal performance by accurately measuring the pressure and temperature within the engine’s system.

ISL Series Engines

- ISL CM2150

- ISL9 CM2250

The ISL series engines, such as the ISL CM2150 and ISL9 CM2250, also utilize the Pressure Temperature Sensor 4921324. This compatibility ensures that the engine operates efficiently and reliably by providing data to the engine control unit.

ISM Series Engines

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM876 and ISM11 CM876 SN, are equipped with the Pressure Temperature Sensor 4921324. This sensor is essential for maintaining the engine’s performance and ensuring that it runs within safe operating parameters.

ISX Series Engines

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines, such as the ISX CM871, ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, are compatible with the Pressure Temperature Sensor 4921324. This sensor is vital for these engines, providing accurate pressure and temperature readings to ensure optimal performance and efficiency.

ISZ Series Engines

- ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine is also compatible with the Pressure Temperature Sensor 4921324. This sensor helps maintain the engine’s performance by providing essential data on pressure and temperature.

QSB Series Engines

- QSB6.7 M CM2250

The QSB6.7 M CM2250 engine is compatible with the Pressure Temperature Sensor 4921324. This sensor ensures that the engine operates efficiently by providing accurate pressure and temperature readings.

QSC and QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM850(CM2850)

The QSC9 CM2250/QSL9 CM2250 and QSL9 CM850(CM2850) engines are compatible with the Pressure Temperature Sensor 4921324. This sensor is essential for maintaining the engine’s performance and ensuring that it operates within safe parameters.

QSK Series Engines

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK95 CM2350 K111 and QSK95 CM2350 K113 engines are compatible with the Pressure Temperature Sensor 4921324. This sensor ensures that the engine operates efficiently by providing accurate pressure and temperature readings.

QSM, QSN, and QSNT Series Engines

- QSM11 CM876

- QSN14 CM876 N103

- QSNT14 CM876 N102

The QSM11 CM876, QSN14 CM876 N103, and QSNT14 CM876 N102 engines are compatible with the Pressure Temperature Sensor 4921324. This sensor is essential for maintaining the engine’s performance and ensuring that it operates within safe parameters.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

The QSX11.9 CM2250 ECF, QSX15 CM2250, and QSX15 CM2250 ECF engines are compatible with the Pressure Temperature Sensor 4921324. This sensor ensures that the engine operates efficiently by providing accurate pressure and temperature readings.

Role of Part 4921324 Pressure Temperature Sensor in Engine Systems

The integration of the Part 4921324 Pressure Temperature Sensor within engine systems is essential for maintaining optimal performance and efficiency. This sensor is strategically positioned to monitor and report the pressure and temperature conditions within the engine, providing vital data that the Engine Control Module (ECM) uses to make real-time adjustments.

Interaction with the Engine Control Module (ECM)

The ECM relies on precise data from the Pressure Temperature Sensor to regulate various engine functions. By continuously receiving updates on pressure and temperature, the ECM can fine-tune fuel injection timing, air-fuel mixture, and ignition timing. This ensures that the engine operates within its optimal parameters, enhancing both performance and fuel efficiency 4.

Contribution to Engine Performance

Incorporating the Pressure Temperature Sensor into the engine system allows for more accurate diagnostics and proactive maintenance. The sensor’s data helps identify potential issues before they escalate into significant problems, such as overheating or inefficient combustion. This proactive approach not only extends the engine’s lifespan but also reduces the likelihood of unexpected breakdowns 1.

Enhanced Fuel Efficiency

By providing real-time pressure and temperature data, the sensor enables the ECM to make instantaneous adjustments that optimize fuel delivery. This results in improved fuel efficiency, as the engine can operate more smoothly and with less wasted energy. The sensor’s role in this process is indispensable for achieving the best possible fuel economy 2.

Support for Emission Control

Modern engines are designed to meet stringent emission standards, and the Pressure Temperature Sensor plays a part in this by ensuring that the engine operates within the parameters set for minimal emissions. The ECM uses the sensor’s data to adjust engine operations, reducing the output of harmful pollutants and helping the vehicle comply with environmental regulations 3.

Facilitation of Smooth Operation

The Pressure Temperature Sensor contributes to the overall smoothness of engine operation by providing consistent and reliable data. This allows the ECM to make subtle but necessary adjustments that prevent rough idling, misfires, and other performance issues. The result is a more responsive and reliable engine that delivers a better driving experience 4.

Conclusion

The Cummins 4921324 Pressure Temperature Sensor is a vital component in ensuring the optimal performance and efficiency of truck engines. By providing accurate and real-time data on pressure and temperature, this sensor enables the engine management system to make necessary adjustments for fuel management, emission control, and overall engine health. Its robust design and compatibility with a wide range of Cummins engines make it an essential part for maintaining vehicle performance and longevity.

-

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ ↩ ↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ ↩ ↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ ↩ ↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.