This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3816952 Tachometer is a specialized instrument designed for use in commercial trucks. It provides a precise measurement of the engine’s rotational speed, commonly referred to as RPM (revolutions per minute). This tachometer is integral to the operation of commercial trucks, offering vital data that aids in engine management and enhances driver awareness.

Basic Concepts of a Tachometer

A tachometer is an instrument that measures the working speed of an engine, typically in revolutions per minute (RPM). It operates by detecting the frequency of pulses generated by the engine’s rotation, converting this data into a readable format displayed on the instrument’s face. The tachometer plays a role in monitoring engine speed, which is crucial for maintaining optimal engine performance and preventing over-revving, which can lead to engine damage 1.

Purpose of the Cummins 3816952 Tachometer

The Cummins 3816952 Tachometer is specifically designed to integrate seamlessly into the operation of commercial trucks. It provides real-time data on engine speed, which is vital for engine management. This information allows drivers and fleet managers to make informed decisions regarding gear changes, load management, and overall engine health. Additionally, it enhances driver awareness by providing immediate feedback on engine performance, contributing to safer and more efficient driving practices.

Key Features

This Cummins part is characterized by several key features that enhance its functionality. These include high accuracy in RPM measurement, ensuring reliable data for engine management. Its durable construction is designed to withstand the rigors of commercial truck environments. Additionally, the tachometer incorporates design elements that facilitate easy reading and integration into the truck’s dashboard, contributing to its overall effectiveness.

Benefits

Utilizing the Cummins 3816952 Tachometer offers several benefits. It contributes to improved engine performance by providing accurate RPM data that aids in optimal gear selection and load management. Enhanced driver safety is another benefit, as the tachometer offers real-time engine speed information, allowing drivers to make timely adjustments to driving conditions. Furthermore, it supports efficient fleet management by offering valuable data for maintenance scheduling and performance monitoring.

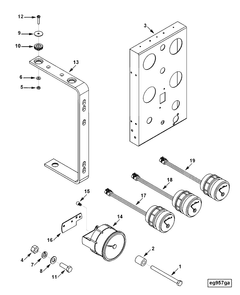

Installation and Integration

Proper installation and integration of the Cummins 3816952 Tachometer within a truck’s dashboard and engine system are crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure accurate readings and seamless integration with the truck’s engine management system. Careful attention to wiring and connections is necessary to avoid issues that could affect the tachometer’s performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3816952 Tachometer may include inaccurate readings or display malfunctions. Troubleshooting these issues often involves checking the wiring and connections for any signs of damage or corrosion. Regular maintenance practices, such as cleaning the tachometer’s face and ensuring all connections are secure, can help ensure its longevity and accurate operation. Consulting the manufacturer’s guidelines for specific troubleshooting and maintenance procedures is recommended.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components for commercial vehicles. The company’s history of innovation and excellence in engine technology underscores its position as a trusted provider of automotive and heavy-duty truck parts, including the Cummins 3816952 Tachometer 2.

Cummins Tachometer Part 3816952 Compatibility

The Cummins Tachometer part number 3816952 is a critical component for monitoring engine performance across various Cummins engine models. This tachometer is designed to provide real-time data on engine speed, ensuring optimal operation and maintenance. Below is a detailed look at the compatibility of this tachometer with specific Cummins engine models.

6C8.3 Engine Series

The 6C8.3 engine series is a robust and reliable option for various applications, including agricultural and industrial machinery. The tachometer part 3816952 is engineered to seamlessly integrate with the 6C8.3 engines, offering precise readings and enhancing the overall efficiency of the engine. This compatibility ensures that operators can monitor engine performance effectively, leading to better maintenance practices and prolonged engine life.

Grouping of Compatible Engines

While the 6C8.3 engine series is a notable example, Cummins offers a range of engines that benefit from the 3816952 tachometer. This part is designed to be versatile, ensuring it fits well within the broader Cummins engine lineup. The compatibility extends to other similar engine models, providing a consistent and reliable monitoring solution across different engine types.

By ensuring that the tachometer part 3816952 is compatible with a variety of Cummins engines, users can maintain a high standard of performance monitoring, regardless of the specific engine model in use. This compatibility is crucial for operators who rely on accurate engine data to optimize their machinery’s performance.

Role of Part 3816952 Tachometer in Engine Systems

The part 3816952 Tachometer is an essential component in the engine instrumentation system, providing real-time data on engine performance. When integrated with the drive system, the tachometer ensures that the rotational speed of the engine is accurately monitored, allowing for precise control over the vehicle’s acceleration and deceleration.

In conjunction with the instrumentation kit, the tachometer offers a comprehensive view of engine operation. This kit typically includes various sensors and gauges that work in harmony to deliver detailed metrics, such as engine temperature, oil pressure, and fuel levels. The tachometer’s role here is to complement these readings by providing instantaneous RPM (revolutions per minute) data, enabling engineers and mechanics to make informed adjustments and diagnoses 3.

The panel where the tachometer is mounted serves as the central hub for all engine instruments. It presents a consolidated display of all critical engine parameters, allowing for quick assessments during both routine checks and emergency situations. The tachometer’s placement on this panel ensures that RPM data is readily accessible, facilitating prompt responses to any anomalies.

Finally, within the broader engine instrument system, the tachometer plays a pivotal role in maintaining engine health. By continuously monitoring RPM, it helps in identifying potential issues such as irregular engine behavior, which could indicate problems like misfires or mechanical wear. This proactive monitoring is key to preventing more severe engine damage and ensuring optimal performance.

Conclusion

The Cummins 3816952 Tachometer is a vital component for commercial truck operations, offering precise RPM measurements that enhance engine management and driver awareness. Its high accuracy, durable construction, and easy integration into truck dashboards make it an invaluable tool for fleet managers and drivers alike. Proper installation, regular maintenance, and understanding its role within the engine instrumentation system are essential for maximizing its benefits and ensuring the longevity and efficiency of commercial truck engines.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.