This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3625502 Tachometer is a specialized instrument designed for use in heavy-duty trucks. It serves to monitor and display the rotational speed of the engine, providing drivers and operators with vital information for efficient and safe vehicle operation. The significance of this tachometer in heavy-duty truck operations lies in its ability to offer real-time data on engine performance, which is essential for maintaining optimal driving conditions and ensuring the longevity of the vehicle’s engine.

Basic Concepts of a Tachometer

A tachometer is an instrument that measures the working speed of an engine, typically in revolutions per minute (RPM). It functions by detecting the frequency of electrical pulses generated by the engine’s ignition system or by a sensor attached to the engine. This data is then converted into a readable format, usually displayed on a gauge or digital screen. The importance of a tachometer in vehicle operation cannot be overstated, as it allows drivers to monitor engine speed, which is vital for gear shifting, load management, and preventing engine over-revving 1.

Purpose of the Cummins 3625502 Tachometer

The Cummins 3625502 Tachometer plays a role in the operation of a truck by accurately monitoring engine speed. This information aids drivers in maintaining efficient driving practices by providing insights into the engine’s performance under various loads and conditions. By keeping an eye on the tachometer, drivers can make informed decisions about gear changes and throttle application, which contribute to fuel efficiency and engine health.

Key Features

The Cummins 3625502 Tachometer is distinguished by its robust design and build quality, tailored to withstand the demanding environments typical of heavy-duty truck operations. It features a clear, easy-to-read display, durable construction, and precise calibration. These attributes ensure reliability and accuracy in engine speed measurement, setting it apart from other models on the market.

Benefits of Using the Cummins 3625502 Tachometer

Incorporating the Cummins 3625502 Tachometer into truck operations offers several advantages. It enhances engine performance monitoring by providing real-time data on engine speed, which is vital for optimal operation. It also increases driver awareness of engine conditions, allowing for more informed driving decisions. Additionally, by enabling better engine management, it can contribute to potential fuel efficiency gains, reducing operational costs over time.

Installation and Integration

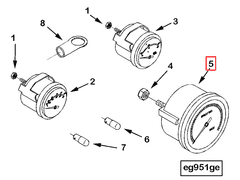

Proper installation and integration of the Cummins 3625502 Tachometer into various truck models require adherence to specific guidelines to ensure compatibility and accurate performance. The setup procedure involves connecting the tachometer to the engine’s ignition system or a dedicated sensor, following the manufacturer’s instructions for wiring and mounting. This ensures that the tachometer operates correctly within the vehicle’s electrical system.

Troubleshooting Common Issues

Frequent problems associated with the Cummins 3625502 Tachometer may include inaccurate readings, display malfunctions, or connectivity issues. Resolving these issues involves checking the wiring connections, ensuring the tachometer is properly calibrated, and verifying that it is compatible with the truck’s engine and electrical system. Step-by-step solutions for these common issues are available to help maintain the tachometer’s optimal performance.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 3625502 Tachometer, regular maintenance practices are recommended. These include cleaning the tachometer’s display and housing, calibrating the instrument to maintain accuracy, and performing routine inspections for any signs of wear or damage. Adhering to these maintenance tips helps preserve the tachometer’s functionality and reliability over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a diverse product range, Cummins has established a reputation for quality and reliability in the automotive industry. This background underscores the quality and dependability of the Cummins 3625502 Tachometer, reflecting the company’s commitment to excellence in engine technology and vehicle components.

Compatibility with Cummins Engines

The Tachometer part 3625502, manufactured by Cummins, is designed to be compatible with a range of Cummins engines, including the 4B3.9, 6B5.9, and 6C8.3 models. This tachometer is engineered to provide precise engine speed readings, ensuring optimal performance and reliability for these engines.

For the 4B3.9 engine, the tachometer integrates seamlessly, offering accurate RPM data crucial for maintaining engine health and efficiency. Similarly, in the 6B5.9 engine, the part ensures that operators can monitor engine speed effectively, aiding in both performance and diagnostic processes.

The 6C8.3 engine also benefits from the 3625502 tachometer, which is specifically calibrated to provide reliable speed readings. This compatibility ensures that the tachometer can be used across multiple Cummins engine models, enhancing the overall operational efficiency and safety of the machinery.

Each engine, while distinct in its specifications and applications, relies on the tachometer to deliver critical data that helps in managing engine performance and preventing potential issues. The 3625502 part is thus a vital component for these engines, ensuring that they operate within their optimal parameters.

Role of Part 3625502 Tachometer in Engine Systems

The Part 3625502 Tachometer is a component in the engine instrument system, providing real-time data on the rotational speed of the engine’s crankshaft. This information is vital for maintaining optimal engine performance and ensuring efficient operation.

Integration with Engine Instrument System

When integrated into the engine instrument system, the Tachometer offers several key functions:

- Real-time Monitoring: It continuously measures the engine’s RPM (revolutions per minute), allowing for immediate feedback on engine speed. This data is displayed on the instrument panel, enabling operators to make timely adjustments.

- Performance Analysis: By tracking RPM changes, the Tachometer helps in diagnosing potential issues such as irregular engine behavior or mechanical faults. This proactive monitoring can prevent more severe problems down the line.

- Operational Efficiency: Accurate RPM readings ensure that the engine operates within its designed parameters, enhancing fuel efficiency and reducing wear and tear on engine components.

Interaction with the Panel

The Tachometer is typically connected to the instrument panel via electrical wiring. This connection allows for the seamless transmission of RPM data to the display unit. The panel usually features a dedicated gauge or digital readout for RPM, making it easy for operators to monitor engine speed at a glance.

Enhanced Diagnostic Capabilities

In modern engine systems, the Tachometer often communicates with other sensors and the engine control unit (ECU). This integration enables more comprehensive diagnostic capabilities, as the ECU can use RPM data in conjunction with other parameters to optimize engine performance and trigger alerts for any anomalies.

Summary of Component Interaction

- Engine Instrument System: The Tachometer is a key component that provides essential RPM data.

- Instrument Panel: Displays the RPM readings, allowing for real-time monitoring by the operator.

- Engine Control Unit (ECU): Utilizes RPM data for advanced diagnostics and performance optimization.

Understanding the role of the Part 3625502 Tachometer in these systems highlights its importance in maintaining engine health and operational efficiency.

Conclusion

The Cummins 3625502 Tachometer is a vital instrument for heavy-duty truck operations, offering real-time engine speed data that enhances performance monitoring, driver awareness, and operational efficiency. Its robust design, precise calibration, and compatibility with various Cummins engines make it a reliable component for maintaining engine health and ensuring efficient vehicle operation.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.