This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3924073 Pressure Switch is a component designed to monitor and regulate pressure within specific systems of commercial trucks. Its role is significant as it ensures the proper functioning of various truck systems by activating or deactivating circuits based on pressure readings. This switch is integral to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Pressure Switches

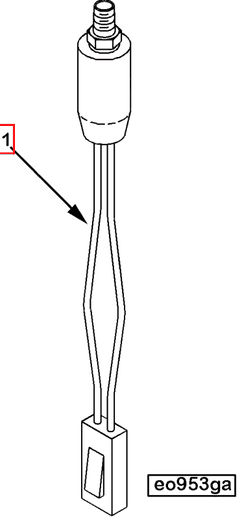

A pressure switch is a device that opens or closes electrical circuits in response to a certain pressure threshold. It consists of a sensing element, a mechanism to convert the sensed pressure into mechanical motion, and an electrical switch. Pressure switches are utilized in a variety of applications, including hydraulic systems, pneumatic systems, and engine management systems, to monitor and control pressure levels 1.

Purpose of the 3924073 Pressure Switch

This Cummins part is specifically designed to play a role in the truck’s systems by monitoring pressure conditions. It is integrated into the truck’s systems to ensure that pressure levels remain within specified limits. When the pressure reaches a certain point, the switch activates or deactivates electrical circuits, which can trigger alarms, adjust system operations, or protect components from damage due to excessive pressure.

Key Features

The 3924073 Pressure Switch is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the demanding conditions of commercial truck environments. Unique characteristics of this switch include its precision in pressure detection, durability, and reliability in various operating conditions. The switch is designed to provide accurate and consistent performance over time.

Benefits of Using the 3924073 Pressure Switch

Utilizing this Cummins part offers several advantages. It contributes to improved system efficiency by ensuring that pressure levels are maintained within optimal ranges. This can lead to enhanced performance and longevity of the truck’s systems. Additionally, the switch’s reliability reduces the likelihood of system failures, which can result in cost savings for fleet operators through decreased downtime and maintenance costs 2.

Installation and Integration

Installing the 3924073 Pressure Switch involves connecting it to the appropriate pressure system and electrical circuits within the truck. It is important to follow manufacturer guidelines to ensure proper integration. This may include verifying system compatibility, ensuring correct wiring, and testing the switch’s functionality post-installation. Special considerations may include system-specific requirements or environmental factors that could affect the switch’s performance.

Troubleshooting and Maintenance

Common issues with the 3924073 Pressure Switch may include inaccurate pressure readings or failure to activate/deactivate circuits. Troubleshooting steps can involve checking electrical connections, verifying pressure system integrity, and testing the switch’s operation. Regular maintenance, such as inspecting for physical damage and ensuring clean, unobstructed connections, can help maintain the switch’s performance. Signs of potential failure may include inconsistent system behavior or warning indicators from the truck’s diagnostic system.

Safety Considerations

When handling, installing, or maintaining the 3924073 Pressure Switch, it is important to observe safety guidelines. This includes ensuring the truck’s systems are de-energized before beginning work, using appropriate personal protective equipment, and following all manufacturer safety recommendations. Proper handling and installation are crucial to prevent injury and ensure the switch operates correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 3.

Cummins Pressure Switch 3924073 Compatibility

The Cummins Pressure Switch 3924073 is designed to ensure the proper functioning of various engine systems by monitoring and regulating pressure levels. This pressure switch is compatible with several Cummins engine models, ensuring reliable performance across different applications.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- QSB5.9 30

- CM550

- V903

Grouped Compatibility

- 4B3.9 and 6B5.9: These engines, often found in medium-duty applications, benefit from the pressure switch’s ability to maintain optimal pressure levels, enhancing overall engine efficiency and longevity.

- 6C8.3 and B4.5: Typically used in heavy-duty applications, these engines rely on the pressure switch to manage pressure variations, ensuring consistent performance under demanding conditions.

- QSB5.9 30: This engine, known for its robust performance in agricultural and industrial settings, integrates the pressure switch to maintain pressure integrity, contributing to reliable operation.

- CM550 and V903: These engines, often utilized in marine and power generation applications, depend on the pressure switch to regulate pressure, ensuring smooth and efficient operation in various environments.

Role of Part 3924073 Pressure Switch in Engine Systems

In the context of engine systems, the Part 3924073 Pressure Switch is instrumental in maintaining optimal performance and safety. This component is primarily integrated into systems where monitoring and regulation of oil pressure are essential.

When installed in an Engine Brake system, the Pressure Switch plays a significant role in ensuring that the brake operates efficiently under varying load conditions. It detects changes in oil pressure and signals the system to adjust accordingly, thus enhancing the durability and responsiveness of the engine brake.

In conjunction with Sensors, the Pressure Switch provides real-time data on oil pressure levels. This information is vital for the engine control unit (ECU) to make informed decisions regarding fuel injection, timing, and other critical parameters. The Pressure Switch acts as a feedback mechanism, allowing the sensor to deliver accurate readings that contribute to the overall efficiency of the engine.

Within the Oil Pressure system, the Pressure Switch is a key component that helps in maintaining the lubrication needs of the engine. It ensures that the oil pressure remains within the desired range, preventing both under-lubrication and over-pressurization. This balance is essential for the longevity and performance of engine components.

Lastly, when integrated with other Switches in the system, the Pressure Switch contributes to a network of monitoring and control. It works in tandem with these switches to create a cohesive system that responds dynamically to the engine’s operational demands. This interplay ensures that the engine operates smoothly, with all subsystems functioning in harmony.

Conclusion

The Cummins 3924073 Pressure Switch is a vital component in the maintenance and operation of commercial truck systems. Its role in monitoring and regulating pressure ensures the efficiency, reliability, and safety of various engine systems. By understanding its features, benefits, and proper installation and maintenance procedures, fleet operators can maximize the performance and longevity of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.