This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3918225 Push Button Switch is a component designed for use in commercial trucks. It serves a specific function within the truck’s electrical system, contributing to the overall operation and functionality of the vehicle. Understanding its purpose and significance can enhance the maintenance and operation of commercial trucks.

Basic Concepts of Push Button Switches

A push button switch is a type of electrical switch that is activated by pressing a button. When the button is pressed, it completes an electrical circuit, allowing current to flow. This mechanism is commonly used in various types of machinery, including trucks, to control different functions and systems. Push button switches are valued for their simplicity, reliability, and ease of use 1.

Purpose of the Cummins 3918225 Push Button Switch

This Cummins part plays a role in the electrical system of a truck by controlling specific functions or systems. It is designed to provide a convenient and reliable method for operators to engage or disengage certain features, enhancing the truck’s operational capabilities 2.

Key Features

The Cummins 3918225 Push Button Switch is characterized by its robust design and the materials used in its construction. It is built to withstand the demanding conditions found in commercial truck environments. Unique attributes of this switch include its durable construction, which ensures longevity and reliable performance, and its straightforward design, which facilitates easy installation and use 3.

Benefits

Using the Cummins 3918225 Push Button Switch offers several advantages. It contributes to improved operational efficiency by providing a reliable means to control truck functions. Its ease of use enhances the driver’s experience, allowing for quick and straightforward operation. Additionally, the switch’s reliability ensures consistent performance, reducing the likelihood of operational interruptions.

Installation and Integration

Installing this Cummins part into a truck’s electrical system requires adherence to specific guidelines to ensure proper function and safety. It is important to follow manufacturer recommendations regarding prerequisites and considerations for installation. This may include ensuring the electrical system is compatible and that the switch is correctly wired to avoid any issues.

Troubleshooting and Maintenance

Common issues with the Cummins 3918225 Push Button Switch may include failure to activate or intermittent operation. Diagnosing problems can involve checking the electrical connections, ensuring the switch is correctly installed, and verifying that there are no underlying issues with the truck’s electrical system. Regular maintenance, such as cleaning the switch and inspecting for wear, can help ensure longevity and optimal performance.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3918225 Push Button Switch, it is important to observe safety practices. This includes ensuring the truck’s electrical system is de-energized before beginning work, using appropriate personal protective equipment, and following all manufacturer guidelines to prevent injury and ensure the safe operation of the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins plays a significant role in the development and production of automotive components, including the 3918225 Push Button Switch. The company’s commitment to excellence is reflected in the design and performance of its products.

Compatibility with Cummins Engines

The Cummins Push Button Switch part number 3918225 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable and efficient operation. This switch is engineered to fit into the operational framework of various Cummins engine models, providing a critical control mechanism for engine functions.

K19 and K38 Engines

The K19 and K38 engines, both known for their robust performance and reliability, are compatible with the Cummins Push Button Switch part 3918225. This switch is engineered to interface with the control systems of these engines, facilitating easy and precise control over engine operations. Its design ensures that it can handle the specific demands of these engines, providing a dependable means of initiating and stopping engine functions.

K50 Engine

The K50 engine, recognized for its advanced engineering and high performance, also benefits from the integration of the Cummins Push Button Switch part 3918225. This switch is meticulously crafted to align with the K50’s sophisticated control architecture, ensuring seamless operation and enhancing the overall user experience. Its compatibility with the K50 engine underscores its versatility and reliability across different engine models.

Integration and Functionality

The Cummins Push Button Switch part 3918225 is designed to be easily integrated into the existing control systems of the K19, K38, and K50 engines. Its robust construction and precise engineering ensure that it can withstand the operational stresses of these engines, providing a long-lasting and dependable solution for engine control. The switch’s compatibility with these engines highlights its versatility and the high standards Cummins maintains in its product design and engineering.

Role of Part 3918225 Push Button Switch in Engine Systems

The Part 3918225 Push Button Switch is an integral component in the operation and control of various engine systems. Its primary function is to provide a manual interface for the operator to engage or disengage specific engine functions.

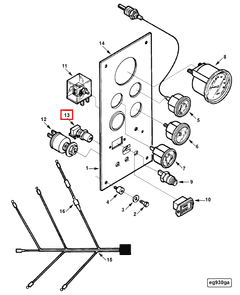

Integration with the Instrument Panel

The Push Button Switch is typically mounted on the instrument panel, where it serves as a direct control point for the operator. When pressed, it sends an electrical signal to the corresponding engine system, allowing for immediate action. This setup ensures that the operator has quick and easy access to essential controls, enhancing the overall efficiency and safety of engine operation.

Interaction with Engine Instruments

In conjunction with engine instruments, the Push Button Switch plays a significant role in monitoring and adjusting engine performance. For instance, it can be used to activate diagnostic modes, allowing the engine instruments to provide real-time data on various parameters such as fuel consumption, temperature, and pressure. This data is vital for making informed decisions and performing necessary adjustments to maintain optimal engine performance.

Panel-Mounted Controls

When installed on a panel, the Push Button Switch offers a centralized control point for multiple engine systems. This configuration allows for streamlined operation, reducing the need for the operator to navigate through complex menus or interfaces. The switch can be programmed to control functions such as ignition, fuel pump activation, or even emergency shutdown procedures, ensuring that critical operations can be performed swiftly and effectively.

Enhanced Operational Control

The Push Button Switch enhances operational control by providing a straightforward method for engaging or disengaging engine systems. This is particularly important in scenarios where rapid response is required, such as in emergency situations or during routine maintenance checks. The switch’s simplicity and reliability make it a preferred choice for critical control functions within engine systems.

Conclusion

The Cummins 3918225 Push Button Switch is a vital component in the electrical systems of commercial trucks and Cummins engines. Its robust design, ease of use, and reliable performance make it an essential tool for operators, enhancing both the efficiency and safety of engine operations. Proper installation, maintenance, and adherence to safety practices are crucial for ensuring the longevity and optimal performance of this switch.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.