Introduction

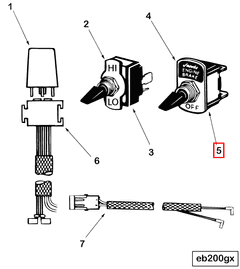

The Cummins 3871459 On/Off Switch is a component designed for use in commercial trucks. Its primary purpose is to provide a simple and reliable method for operators to control the power supply to specific electrical systems within the truck. This switch is integral to ensuring that various electrical components can be activated or deactivated as needed, contributing to the overall functionality and safety of the vehicle 1.

Basic Concepts of On/Off Switches

On/off switches are fundamental components in electrical systems, serving to control the flow of electricity to connected devices. When the switch is in the “on” position, it completes the electrical circuit, allowing current to flow and power the device. Conversely, when the switch is in the “off” position, the circuit is broken, stopping the flow of electricity and deactivating the device. These switches are vital for the safe and efficient operation of electrical systems, providing a straightforward means of control 2.

Role of the Cummins 3871459 On/Off Switch in Truck Operation

The Cummins 3871459 On/Off Switch plays a specific role in the operation of a commercial truck by allowing the operator to control the power supply to certain electrical systems. This switch is integrated into the truck’s electrical system, providing a direct link between the operator’s actions and the activation or deactivation of targeted components. Its reliable operation ensures that electrical systems can be managed effectively, contributing to the truck’s overall performance and safety 3.

Key Features

The Cummins 3871459 On/Off Switch is characterized by several key features that enhance its functionality and durability. These include a robust construction designed to withstand the rigors of commercial truck environments, ease of use with a simple on/off mechanism, and design specifications that ensure compatibility with a range of electrical systems. These features contribute to the switch’s reliability and effectiveness in commercial truck applications 4.

Benefits of Using the Cummins 3871459 On/Off Switch

Utilizing the Cummins 3871459 On/Off Switch offers several advantages. Its reliable operation ensures that electrical systems can be controlled with precision, enhancing the efficiency of truck operations. The switch’s design also contributes to safety by providing a clear and straightforward means of controlling power to electrical components. Additionally, its durability ensures long-term performance, reducing the need for frequent replacements 5.

Installation and Integration

Proper installation and integration of the Cummins 3871459 On/Off Switch within a truck’s electrical system are crucial for its effective operation. Guidelines for installation include ensuring the switch is correctly wired to the electrical system it controls, securing it in a location that is easily accessible to the operator, and verifying that all connections are secure and insulated to prevent electrical issues. Following these guidelines ensures the switch functions as intended within the truck’s electrical system 6.

Troubleshooting Common Issues

Identifying and resolving common problems associated with the Cummins 3871459 On/Off Switch can help maintain its effectiveness. Common issues may include the switch failing to operate, intermittent operation, or physical damage to the switch. Troubleshooting techniques involve checking the electrical connections for security and integrity, inspecting the switch for physical damage, and ensuring that the switch is correctly installed within the electrical system. Addressing these issues promptly can help maintain the switch’s functionality 7.

Maintenance Recommendations

To ensure the longevity and optimal performance of the Cummins 3871459 On/Off Switch, regular maintenance is recommended. This includes inspecting the switch for signs of wear or damage, ensuring that all electrical connections are secure and free from corrosion, and cleaning the switch and its surrounding area to prevent the accumulation of dirt or debris. Adhering to these maintenance practices can help extend the life of the switch and ensure reliable operation 8.

Safety Considerations

When handling and working with the Cummins 3871459 On/Off Switch, it is important to observe several safety guidelines. These include ensuring that the truck’s electrical system is de-energized before performing any maintenance or installation work on the switch, using appropriate personal protective equipment (PPE) to protect against electrical hazards, and following all manufacturer guidelines and instructions for the safe use and maintenance of the switch. Observing these safety considerations helps protect both the operator and the equipment 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3871459 On/Off Switch, which is designed to meet the demanding requirements of commercial truck applications 10.

Conclusion

The Cummins 3871459 On/Off Switch is a vital component in the operation of commercial trucks, providing a reliable and straightforward method for controlling the power supply to electrical systems. Its robust construction, ease of use, and compatibility with a range of electrical systems make it an essential part of ensuring the efficiency and safety of truck operations. Regular maintenance and adherence to safety guidelines are crucial for maintaining the switch’s functionality and longevity.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411375.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.