This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3395705 Pressure Switch is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and safety of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a certain fluid pressure. It is commonly used in various systems to monitor and control pressure levels. When the pressure reaches a predetermined set point, the switch activates or deactivates, allowing for automated control of systems based on pressure conditions 1.

Purpose of the 3395705 Pressure Switch

The Cummins 3395705 Pressure Switch is integrated into a truck’s systems to monitor specific pressure conditions. It plays a role in ensuring that the system operates within safe and efficient parameters. By detecting changes in pressure, it helps in maintaining the optimal performance of the truck’s components, thereby contributing to the overall functionality of the vehicle.

Key Features

The 3395705 Pressure Switch is characterized by its robust design and the quality materials used in its construction. These features enhance its durability and reliability under the demanding conditions typical of commercial truck operations. Its design allows for precise pressure detection, ensuring accurate system responses 2.

Benefits

The advantages of using the 3395705 Pressure Switch include improved system efficiency, enhanced safety through precise pressure monitoring, and potential cost savings for fleet operators due to reduced maintenance needs and increased system longevity 3.

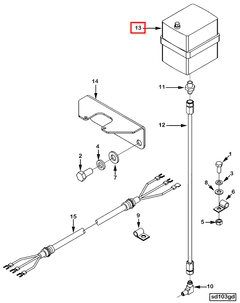

Installation and Integration

Proper installation of the 3395705 Pressure Switch is crucial for its effective operation. It should be integrated into the truck’s system according to manufacturer guidelines, ensuring all prerequisites are met for optimal performance. This includes correct placement and secure connection to avoid issues related to pressure detection accuracy.

Troubleshooting and Maintenance

Common issues with the 3395705 Pressure Switch may include inaccurate pressure readings or failure to activate under the correct conditions. Regular maintenance, such as checking connections and ensuring the switch is free from debris, can help prevent these issues. Signs of wear or malfunction may indicate the need for replacement or repair.

Common Applications

The 3395705 Pressure Switch is typically employed in systems where precise pressure monitoring is necessary. Its applications range from engine systems to hydraulic and pneumatic systems, demonstrating its versatility and importance in various truck operations.

Safety Considerations

When working with the 3395705 Pressure Switch, it is important to observe safety guidelines. This includes proper handling during installation and maintenance, ensuring the system is depressurized when necessary, and following all manufacturer recommendations to prevent accidents or damage to the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a comprehensive product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the 3395705 Pressure Switch.

Cummins Pressure Switch 3395705 in Engine Applications

The Cummins Pressure Switch 3395705 is a critical component in various engine systems, ensuring optimal performance and safety. This part is designed to monitor and regulate pressure levels within the engine’s system, providing essential feedback to the engine control unit (ECU).

G855 Engines

In the G855 engine series, the Pressure Switch 3395705 plays a pivotal role in maintaining the integrity of the engine’s pressure systems. It is integrated into the engine’s design to provide real-time data on pressure variations, which is crucial for the ECU to make necessary adjustments. This ensures that the engine operates within safe parameters, preventing potential damage from overpressure or underpressure conditions.

Grouping of Engines

The Pressure Switch 3395705 is also compatible with other Cummins engines that share similar design and operational requirements. These engines benefit from the switch’s ability to maintain consistent pressure levels, contributing to overall engine efficiency and longevity. By ensuring that pressure remains within specified limits, the switch helps in reducing wear and tear on engine components, thereby extending the engine’s operational life.

Importance in Engine Performance

The integration of the Pressure Switch 3395705 in Cummins engines is a testament to the manufacturer’s commitment to quality and reliability. This part is engineered to withstand the rigors of engine operation, providing accurate and reliable pressure readings. Its role in the engine’s feedback loop is essential for maintaining optimal performance and ensuring that the engine runs smoothly under various conditions.

Role of Part 3395705 Pressure Switch in Engine Systems

The Part 3395705 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and safety. Its primary function is to monitor and regulate pressure within the system, providing essential feedback to the engine control unit (ECU).

Integration with Oil Pressure Systems

In oil pressure systems, the Part 3395705 Pressure Switch constantly monitors the oil pressure. When the pressure falls below a predetermined threshold, the switch sends a signal to the ECU, which then activates warning lights or takes corrective actions to prevent engine damage. This ensures that the engine receives adequate lubrication under all operating conditions.

Function in Coolant Systems

Within coolant systems, the Part 3395705 Pressure Switch plays a significant role in maintaining the correct pressure levels. It helps in detecting any leaks or irregularities in the coolant flow, ensuring that the engine operates within safe temperature ranges. This is particularly important in preventing overheating, which can lead to severe engine damage.

Role in Heater Systems

In heater systems, the Part 3395705 Pressure Switch ensures that the coolant flow is consistent and within the required pressure limits. This is essential for efficient heat transfer to the cabin, providing comfort to the occupants. The switch helps in maintaining the balance between the engine’s cooling needs and the heating requirements of the vehicle’s interior.

Application in Starting Systems

The Part 3395705 Pressure Switch also finds its application in starting systems, where it ensures that the engine starts only when the oil pressure is sufficient. This prevents the engine from starting under low oil pressure conditions, which could result in immediate damage. The switch acts as a safeguard, ensuring that the engine starts only when all conditions are optimal.

Coordination with Other Switches

The Part 3395705 Pressure Switch often works in conjunction with other switches and sensors within the engine system. For instance, it may interact with the Aid Switch to provide a comprehensive monitoring solution. This coordinated effort ensures that all aspects of the engine’s performance are closely monitored and regulated, leading to enhanced reliability and efficiency.

Conclusion

The Cummins 3395705 Pressure Switch is a vital component in the operation of commercial trucks, particularly in engine systems. Its role in monitoring and regulating pressure ensures the safety and efficiency of the vehicle. Proper installation, regular maintenance, and adherence to safety guidelines are essential for the optimal performance of this Cummins part. Its integration into various engine systems underscores the importance of precise pressure monitoring in maintaining engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.