2897324

Pressure Switch

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2897324 Pressure Switch is a component designed for use in commercial trucks, manufactured by Cummins Inc., a leading provider of diesel engines, related technologies, and customer support services. This part plays a role in monitoring and regulating various pressure levels within the truck’s system, ensuring optimal performance and safety.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves in response to changes in pressure, activating a switch that controls the flow of electricity. Pressure switches are commonly used in automotive systems to manage fluid levels, control compressors, and regulate engine functions, among other applications 1.

Role of the 2897324 Pressure Switch in Truck Operation

The Cummins 2897324 Pressure Switch performs several functions within the truck’s system. It monitors pressure levels in critical areas, such as the fuel system or hydraulic circuits, and sends signals to the truck’s control unit to adjust operations as needed. This switch interacts with other components to maintain pressure within safe and efficient ranges, contributing to the overall performance and reliability of the truck 2.

Key Features of the 2897324 Pressure Switch

The Cummins 2897324 Pressure Switch is characterized by its robust design, which includes high-quality materials resistant to wear and environmental factors. It incorporates advanced technology to ensure precise pressure monitoring and reliable operation. The switch is engineered to withstand the demanding conditions of commercial truck use, providing durability and consistent performance 3.

Benefits of Using the 2897324 Pressure Switch

Utilizing the Cummins 2897324 Pressure Switch offers several advantages. It enhances the efficiency of the truck’s system by ensuring that pressure levels are maintained within optimal ranges. This contributes to improved fuel efficiency, reduced wear on components, and enhanced overall performance. The switch’s reliability and precision also contribute to safer truck operations 4.

Installation and Integration

Installing the Cummins 2897324 Pressure Switch involves connecting it to the appropriate pressure lines within the truck’s system and ensuring it is properly secured. Integration requires careful attention to the manufacturer’s guidelines to ensure compatibility with the truck’s existing components and systems. Proper installation is key to ensuring the switch functions correctly and contributes to the truck’s performance.

Maintenance and Troubleshooting

Maintaining the Cummins 2897324 Pressure Switch is important for ensuring its long-term reliability and performance. Regular inspections for signs of wear or damage, and cleaning the switch and its connections, are recommended practices. Common issues may include inaccurate pressure readings or failure to activate, which can often be resolved by checking connections, cleaning the switch, or replacing worn components.

Safety Considerations

When working with the Cummins 2897324 Pressure Switch, it is important to observe safety practices. This includes ensuring the truck’s system is depressurized before beginning any work, using appropriate personal protective equipment, and following all manufacturer guidelines for handling and installation. Adhering to these safety considerations helps prevent accidents and ensures the safe operation of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes diesel and natural gas engines, as well as related technologies and services, serving a wide array of industries and applications.

Pressure Switch 2897324 Compatibility with Cummins Engines

The Pressure Switch 2897324, manufactured by Cummins, is a component designed to monitor and regulate pressure within various engine systems. This part is compatible with several Cummins engine models, ensuring reliable performance across different applications.

Compatibility with ISBE CM800

The ISBE CM800 engine benefits from the Pressure Switch 2897324, which is integral to maintaining optimal pressure levels. This switch helps in detecting and responding to pressure fluctuations, thereby enhancing the engine’s efficiency and longevity.

Compatibility with QSK95 CM2350 K111 and QSK95 CM2350 K113

Both the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines are equipped with the Pressure Switch 2897324. This part ensures that the engines operate within safe pressure parameters, preventing potential damage from overpressure or underpressure conditions. Its precise functionality is crucial for maintaining the high performance standards expected from these engines.

Compatibility with VTA903 CM2250 V105

The VTA903 CM2250 V105 engine also utilizes the Pressure Switch 2897324. This component plays a vital role in the engine’s pressure management system, ensuring that the engine runs smoothly and efficiently. Its compatibility with this engine model underscores its versatility and importance in various engine applications.

Role of Part 2897324 Pressure Switch in Engine Systems

The part 2897324 Pressure Switch is a component in various engine systems, contributing to the overall functionality and efficiency of the engine.

Integration with Engine Control Module (ECM)

The Pressure Switch interfaces with the Engine Control Module (ECM) to monitor and regulate pressure levels within the engine. This interaction allows the ECM to make real-time adjustments to engine performance based on pressure readings, ensuring optimal operation under varying conditions.

Function in Engine Overhaul Kit

When included in an Engine Overhaul Kit, the Pressure Switch plays a role in diagnosing and maintaining pressure integrity during the overhaul process. It helps in identifying any pressure discrepancies that may arise from worn or damaged components, facilitating precise repairs and replacements.

Collaboration with Primer System

In conjunction with the Primer System, the Pressure Switch ensures that the fuel system is pressurized correctly before engine start-up. This pre-start pressurization is vital for smooth engine ignition and consistent fuel delivery, reducing the likelihood of start-up issues and enhancing engine reliability.

Role in Engine Lubricating System

The Pressure Switch also contributes to the Engine Lubricating System by monitoring oil pressure levels. It provides feedback to the ECM, which can then adjust the oil pump’s operation to maintain adequate lubrication across all moving parts. This ensures that the engine components are well-lubricated, reducing wear and tear and prolonging engine life.

Conclusion

By effectively integrating with these systems, the part 2897324 Pressure Switch enhances the engine’s performance, reliability, and longevity, making it a valuable component in engine maintenance and operation.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩

SPECIFICATIONS

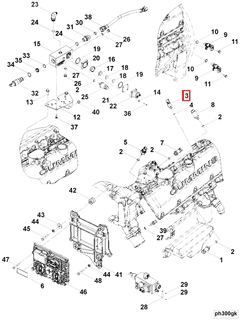

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3678912 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.