Introduction

The Cummins 2872933 Fluid Level Switch is a component designed to monitor fluid levels within commercial trucks. It plays a role in ensuring the proper operation of various truck systems by detecting fluid levels and signaling when they fall below a specified threshold. This switch is integral to maintaining system functionality and preventing potential damage due to low fluid levels 1.

Basic Concepts of Fluid Level Switches

A Fluid Level Switch is a device that detects the level of liquid within a tank or reservoir. It operates using a float mechanism, electrical contacts, or other sensing technologies to determine the fluid level. When the fluid reaches a certain point, the switch activates or deactivates an electrical circuit, triggering an alert or automated response. These switches are commonly used in automotive and industrial applications to manage fluids such as oil, coolant, and fuel 2.

Purpose of the Cummins 2872933 Fluid Level Switch

The Cummins 2872933 Fluid Level Switch is specifically designed to monitor the levels of critical fluids in commercial trucks. It interacts with systems such as the engine oil, transmission fluid, and coolant reservoirs. By accurately detecting fluid levels, it helps maintain optimal performance and prevents issues that could arise from insufficient fluid, such as engine overheating or lubrication failure 3.

Key Features

The Cummins 2872933 Fluid Level Switch is characterized by its robust design and high-quality materials, ensuring durability in demanding truck environments. It incorporates advanced sensing technology to provide accurate fluid level readings. The switch is engineered to withstand vibrations, temperature fluctuations, and other operational stresses commonly encountered in commercial trucking.

Benefits

Utilizing the Cummins 2872933 Fluid Level Switch offers several advantages. It contributes to improved system efficiency by ensuring that fluid levels are maintained within the required parameters. This enhances the overall reliability and safety of the truck’s operation. Additionally, the switch helps in early detection of fluid leaks or consumption, allowing for timely maintenance and reducing the risk of system failures.

Installation and Integration

Installing the Cummins 2872933 Fluid Level Switch involves mounting it in the appropriate fluid reservoir and connecting it to the truck’s electrical system. Preparatory steps include ensuring the reservoir is clean and free of debris. The switch should be securely fastened to prevent movement that could affect its accuracy. Integration with the truck’s monitoring system allows for real-time fluid level alerts.

Troubleshooting and Maintenance

Common issues with the Cummins 2872933 Fluid Level Switch may include inaccurate readings or failure to activate. Troubleshooting steps involve checking the electrical connections, ensuring the switch is properly positioned, and verifying the fluid level within the reservoir. Regular maintenance includes inspecting the switch for signs of wear or corrosion and ensuring it remains clean and functional. If the switch shows consistent malfunctions, replacement may be necessary.

Common Applications

The Cummins 2872933 Fluid Level Switch is typically used in various commercial trucks, including semi-trucks, delivery trucks, and construction vehicles. It is employed in systems requiring precise fluid level monitoring, such as engine oil systems, transmission fluid reservoirs, and coolant systems. Its application ensures that these critical fluids are maintained at optimal levels for efficient and safe truck operation.

Safety Considerations

When working with the Cummins 2872933 Fluid Level Switch, it is important to follow safety guidelines. This includes ensuring the truck’s engine is off and the electrical system is disconnected before installation or maintenance. Handling fluids requires caution to avoid spills and contact with skin. Additionally, electrical components should be managed with care to prevent short circuits or shocks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and commercial truck industry. The company is committed to innovation, quality, and customer satisfaction, providing reliable solutions for a wide range of applications.

Compatibility

The Cummins Fluid Level Switch part number 2872933 is designed to be compatible with a variety of Cummins engines. Here is a breakdown of its compatibility across different engine models:

ISB6.7 Engines

- ISB6.7 CM2350 B101: This engine variant is equipped with the Fluid Level Switch 2872933 to ensure accurate monitoring of fluid levels, maintaining optimal engine performance.

QSK19 Engines

- QSK19 CM2350 K105: The Fluid Level Switch 2872933 is used in this engine to provide reliable fluid level indication, crucial for preventing engine damage due to low fluid levels.

- QSK19 CM2350 K114: Similar to the K105 variant, this engine also utilizes the 2872933 switch for effective fluid level management.

- QSK19 CM850 MCRS: This engine model incorporates the 2872933 switch to ensure that fluid levels are consistently monitored, contributing to the engine’s overall reliability.

QSK50 Engines

- QSK50 CM2150 K107: The Fluid Level Switch 2872933 is integrated into this engine to provide precise fluid level readings, which are essential for maintaining engine efficiency and longevity.

QSK95 Engines

- QSK95 CM2350 K111: This engine model uses the 2872933 switch to monitor fluid levels, ensuring that the engine operates within safe parameters.

- QSK95 CM2350 K113: Similar to the K111 variant, the 2872933 switch is employed in this engine to maintain accurate fluid level monitoring.

The Fluid Level Switch 2872933 is a critical component for these engines, ensuring that fluid levels are consistently monitored and maintained at optimal levels, thereby contributing to the overall reliability and performance of the engine.

Role in Engine Systems

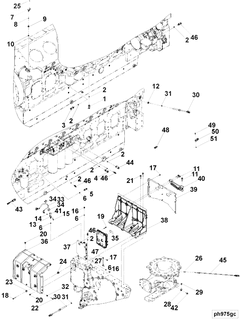

The Cummins 2872933 Fluid Level Switch is an integral component in the management and monitoring of fluid levels within engine systems. It works in conjunction with several key components to ensure optimal engine performance and protection.

Interaction with Coolant Level Sensor

The Fluid Level Switch interfaces with the Coolant Level Sensor to provide accurate readings of the coolant level within the engine. This interaction allows for real-time monitoring, ensuring that the coolant remains within the necessary parameters to prevent overheating and maintain efficient engine operation.

Coordination with Coolant Level Switch

In tandem with the Coolant Level Switch, Part 2872933 plays a significant role in detecting the precise level of coolant. This coordination is vital for triggering alerts or actions when the coolant level falls below a safe threshold, thereby preventing potential engine damage due to insufficient coolant.

Communication with Engine Control Module (ECM)

The Fluid Level Switch sends signals to the Engine Control Module (ECM), providing essential data on the coolant level. The ECM uses this information to adjust engine parameters, such as fuel injection and ignition timing, to optimize performance while safeguarding the engine from overheating.

Integration with Engine Coolant Level Sensor

Finally, the Fluid Level Switch works in harmony with the Engine Coolant Level Sensor to offer a comprehensive monitoring system. This integration ensures that any fluctuations in coolant levels are promptly detected and addressed, maintaining the engine’s efficiency and longevity.

Conclusion

The Cummins 2872933 Fluid Level Switch is a vital component in the maintenance and operation of commercial trucks. By accurately monitoring fluid levels, it ensures the optimal performance and safety of various truck systems. Its robust design, advanced sensing technology, and compatibility with a range of Cummins engines make it an essential part for maintaining engine reliability and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.