This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

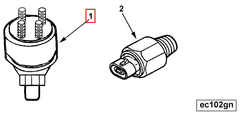

The Cummins 212614 Pressure Switch is a component designed for use in commercial trucks. It plays a role in maintaining optimal vehicle performance by monitoring and regulating pressure within specific systems. Understanding its function and significance can help in ensuring the efficient operation of commercial trucks.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves when pressure changes, activating a switch that controls electrical signals. Pressure switches are commonly used in various automotive systems to manage fluid levels, air pressure, and other critical parameters 1.

Purpose of the 212614 Pressure Switch

This Cummins part is specifically designed to monitor and regulate pressure within the truck’s systems. It ensures that the pressure remains within safe and efficient operating ranges, which is vital for the proper functioning of the truck’s components. This switch helps in maintaining system integrity and performance by providing accurate pressure readings and triggering necessary actions when pressure levels deviate from the set thresholds 2.

Key Features

The 212614 is characterized by its robust design and high-quality materials. It features a durable housing that protects internal components from environmental factors. The switch is engineered to provide precise pressure readings and reliable operation under varying conditions. Additionally, it includes unique attributes such as corrosion-resistant materials and a compact design that allows for easy integration into the truck’s systems 3.

Benefits

This Cummins part offers several advantages. It contributes to improved system efficiency by ensuring that pressure levels are maintained within optimal ranges. This results in enhanced reliability and performance of the truck’s systems. The switch also helps in preventing potential issues that could arise from pressure fluctuations, thereby contributing to the overall performance and longevity of the vehicle.

Installation and Integration

Installing the 212614 involves connecting it to the appropriate pressure lines within the truck’s system. It is important to follow manufacturer guidelines to ensure proper setup. This may include verifying that the pressure lines are clean and free from obstructions, securing the switch in place, and testing the system to confirm that the switch is functioning correctly. Proper installation is key to ensuring the switch operates effectively within the truck’s systems.

Troubleshooting and Maintenance

Common issues with the 212614 may include inaccurate pressure readings or failure to activate at the correct pressure levels. Diagnostic procedures involve checking the switch for physical damage, ensuring that it is properly connected, and verifying that the pressure lines are clear of debris. Regular maintenance practices, such as inspecting the switch for signs of wear and ensuring that all connections are secure, can help in maintaining its longevity and optimal performance.

Performance Impact

The 212614 plays a role in the overall performance of the truck by ensuring that pressure levels within the systems are maintained at optimal levels. This can contribute to improved fuel efficiency, enhanced engine performance, and increased system reliability. By providing accurate pressure readings and triggering necessary actions, the switch helps in maintaining the efficiency and effectiveness of the truck’s operations.

Safety Considerations

When working with the 212614, it is important to follow safety protocols. This includes ensuring that the truck’s systems are depressurized before beginning any work, using appropriate personal protective equipment, and following manufacturer guidelines for installation and maintenance. Adhering to these safety measures helps in protecting both the technician and the vehicle during handling, installation, and maintenance procedures.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and a diverse product range, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is reflected in its products, including the 212614, which is designed to meet the demanding requirements of commercial truck applications.

Pressure Switch 212614 Compatibility with Cummins Engines

The Pressure Switch 212614, manufactured by Cummins, is a critical component in various engine systems, ensuring optimal performance and safety. This switch is designed to fit seamlessly with several Cummins engine models, providing reliable pressure monitoring and control.

K-Series Engines

The Pressure Switch 212614 is compatible with the K19, K38, and K50 engines. These engines are known for their robust design and efficiency, making them suitable for a range of heavy-duty applications. The switch integrates smoothly with the engine’s pressure systems, ensuring precise monitoring and control.

N-Series Engines

For the N14 MECHANICAL engine, the Pressure Switch 212614 is an essential part of the engine’s pressure management system. This engine is renowned for its durability and power, often used in demanding industrial and transportation sectors. The switch’s compatibility with the N14 MECHANICAL ensures that the engine operates within safe pressure limits, enhancing longevity and performance.

NH/NT Series Engines

The NH/NT 855 engines also benefit from the Pressure Switch 212614. These engines are designed for high-performance applications, and the switch plays a crucial role in maintaining the necessary pressure levels. Its integration with the NH/NT 855 ensures that the engine runs efficiently and safely, even under heavy loads.

V-Series Engines

Lastly, the V28 engine is another model that can utilize the Pressure Switch 212614. This engine is known for its versatility and power, making it suitable for various applications. The switch’s compatibility with the V28 ensures that the engine’s pressure systems are monitored and controlled effectively, contributing to the engine’s overall reliability and performance.

Role of Part 212614 Pressure Switch in Engine Systems

The part 212614 Pressure Switch is integral to the operation of various engine systems, ensuring optimal performance and safety. In the context of NFPA (National Fire Protection Association) switches, this pressure switch plays a significant role in monitoring and controlling the pressure levels within the system.

Integration with NFPA Switches

When integrated with NFPA switches, the part 212614 Pressure Switch enhances the system’s ability to detect and respond to pressure variations. NFPA switches are designed to meet specific safety standards, and the addition of the pressure switch ensures that these standards are maintained under varying operational conditions.

Function in Hydraulic Systems

In hydraulic systems, the pressure switch monitors the fluid pressure and signals the NFPA switch to activate or deactivate certain functions based on the pressure readings. This helps in maintaining the desired pressure levels, preventing system overload, and ensuring smooth operation.

Application in Pneumatic Systems

For pneumatic systems, the part 212614 Pressure Switch works in conjunction with NFPA switches to regulate air pressure. This is particularly important in applications where precise pressure control is necessary to avoid component damage or system failure.

Role in Fuel Systems

In fuel systems, the pressure switch ensures that the fuel pressure remains within safe limits. By communicating with NFPA switches, it helps in maintaining consistent fuel delivery, which is essential for engine efficiency and performance.

Contribution to Safety Systems

The pressure switch also contributes to the overall safety of the engine system. By providing real-time pressure data to NFPA switches, it enables the system to take corrective actions promptly, thereby enhancing safety and reliability.

Enhancement of System Efficiency

By ensuring that pressure levels are maintained within optimal ranges, the part 212614 Pressure Switch, in collaboration with NFPA switches, enhances the efficiency of the engine system. This results in better performance, reduced wear and tear, and longer component lifespan.

Conclusion

The Cummins 212614 Pressure Switch is a vital component in the operation of commercial trucks and various engine systems. Its role in monitoring and regulating pressure ensures optimal performance, safety, and efficiency. Understanding its function, benefits, and integration with other systems can help in maintaining the vehicle’s overall performance and longevity.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan and Avinash Kumar, Springer Nature, 2020

↩ -

Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, David C Barton and John D Fieldhouse, Elsevier, 2009

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.