This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

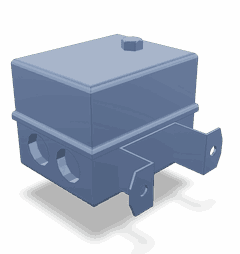

The Cummins 196074 Pressure Switch is designed for commercial truck operations, monitoring and regulating pressure within specific systems to ensure safe and efficient operation. This part interacts with various systems to maintain vehicle functionality and performance under different conditions.

Basic Concepts of Pressure Switches

A pressure switch operates by opening or closing electrical circuits in response to a certain pressure threshold. It uses a diaphragm or piston to activate a mechanism that makes or breaks an electrical connection. These switches are used in automotive systems to control functions such as engine lubrication and fuel delivery, ensuring systems operate within their designed pressure ranges 1.

Role of the 196074 Pressure Switch in Truck Operation

This Cummins part monitors pressure levels in specific areas, such as the fuel or hydraulic systems, and sends signals to the truck’s control unit when pressure levels fall outside the normal operating range. This allows the system to make adjustments or trigger warnings to the driver, helping to prevent damage to the engine or other components.

Key Features

The 196074 is characterized by its robust design and the materials used in its construction, which contribute to its durability and reliability. It is engineered to withstand harsh conditions often encountered in commercial truck operations. Unique attributes include its precision in detecting pressure changes and its ability to operate effectively across a wide range of temperatures and environments.

Benefits of Using the 196074 Pressure Switch

Utilizing this part offers several advantages. It contributes to improved system efficiency by ensuring that pressure levels are maintained within optimal ranges, which can lead to better fuel economy and reduced wear on components. Its reliability reduces the likelihood of system failures, resulting in cost savings for fleet operators through decreased downtime and maintenance costs.

Installation and Integration

Proper installation of the 196074 is vital for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific mounting locations and electrical connections. Consideration should be given to the switch’s orientation and the routing of any associated wiring to prevent damage and ensure reliable operation.

Troubleshooting and Maintenance

Common issues with the 196074 may include inaccurate pressure readings or failure to activate under the correct conditions. Diagnostic procedures involve checking the switch’s electrical connections, testing its response to pressure changes, and inspecting for physical damage. Regular maintenance, such as cleaning the switch and its connections, can help ensure longevity and consistent performance.

Safety Considerations

When working with the 196074, it is important to observe safety practices and precautions. This includes ensuring the truck’s engine is off and the system is depressurized before beginning any work. Proper handling, installation, and maintenance procedures should be followed to prevent injury and ensure the switch operates correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and transportation markets worldwide, providing reliable and efficient power solutions for a variety of applications.

Compatibility with Various Engines

This part is compatible with a range of Cummins engines, including K-Series, N-Series, QSK, V-Series, and NH/NT engines. It ensures that these engines operate within safe pressure limits, preventing potential damage from over-pressurization and enhancing performance and reliability.

Role in Engine Systems

The 196074 is integral to various engine systems, ensuring optimal performance and safety. Its primary function is to monitor and regulate pressure within the system, adapting to changing conditions to maintain efficiency.

Integration with Starting Aids

In systems equipped with Coolant Heater Starting Aid or Injection Starting Aid, the pressure switch ensures that the pressure within the coolant or injection system remains within specified limits, which is particularly important during cold starts 2.

Cold Start Applications

For Cold Start Aid and Cold Starting Aid systems, the pressure switch helps manage pressure build-up as the engine warms up, preventing excessive pressure that could lead to system failures or inefficiencies.

Coolant and Engine Heater Systems

In Coolant Heater, Coolent Heater, and Engine Coolant Heater systems, the pressure switch is vital for maintaining the right pressure levels, which is crucial for the effective circulation of coolant and preventing engine overheating.

Heater and Engine Water Systems

The pressure switch is also employed in Heater and Engine Water systems to ensure that the pressure within these systems is optimal, facilitating efficient heat transfer and water circulation.

Hot Start Plumbing and Water Jacket Heater Kits

In Hotstart Plumbing and Water Jacket Heater Kit systems, the pressure switch helps regulate the pressure within the water jacket, ensuring the engine reaches the desired temperature quickly and efficiently.

Kim Hot Start Systems

For Kim Hot Start 115V.2500 W, Kim Hot Start 230V.2500 W, Kim Hotstart 230V.4000 W, and Kim Hotstart 230V.8000 W systems, the pressure switch ensures that the pressure within these high-power heating systems is maintained at optimal levels, facilitating efficient and safe operation.

Safety Controls and Water Heater Systems

In Safety Controls Assembly and Water Heater systems, the pressure switch acts as a safeguard, monitoring pressure levels and triggering safety mechanisms if pressure exceeds safe limits, preventing potential hazards and ensuring system integrity.

Water Jacket Heater and Kit Systems

Finally, in Water Jacket Heater and Water Jacket Kit systems, the pressure switch is essential for maintaining the correct pressure within the water jacket, ensuring efficient heat distribution and engine temperature regulation.

Conclusion

The Cummins 196074 Pressure Switch is a critical component in maintaining the efficiency and safety of commercial truck operations. Its robust design, precise pressure detection, and compatibility with various Cummins engines make it an invaluable part of engine systems. Proper installation, regular maintenance, and adherence to safety practices are essential to ensure its optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.