3060538

Support Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3060538 Support Gasket is a specialized component designed for use in heavy-duty truck engines. Its purpose is to provide a reliable seal and support within the engine assembly, ensuring optimal performance and longevity of the engine.

Basic Concepts of Support Gaskets

Support gaskets are sealing components used in various types of machinery, including engines. They are designed to fill the space between two or more mating surfaces, preventing the leakage of fluids and gases while providing structural support. In engines, support gaskets play a role in maintaining the integrity of the sealing surfaces, which is important for the efficient operation of the engine 1.

Purpose of the Cummins 3060538 Support Gasket

The Cummins 3060538 Support Gasket is positioned within the engine assembly to seal and support specific components. It ensures that there are no leaks between mating surfaces, which could lead to a loss of efficiency or damage to the engine. By maintaining a secure seal, the gasket contributes to the overall performance and reliability of the engine 2.

Key Features

The Cummins 3060538 Support Gasket is crafted from high-quality materials that offer durability and resistance to the harsh conditions within an engine. Its design includes precise dimensions and a robust construction that ensures a perfect fit and long-lasting performance. The gasket may also feature unique characteristics such as enhanced flexibility or resistance to thermal expansion, which further contribute to its effectiveness 3.

Benefits of Using the Cummins 3060538 Support Gasket

Incorporating the Cummins 3060538 Support Gasket into truck engines offers several advantages. It helps to maintain engine performance by ensuring a reliable seal, which prevents leaks that could otherwise reduce efficiency. The gasket’s durability contributes to the engine’s longevity, while its precise fit enhances overall reliability 4.

Installation Process

To install the Cummins 3060538 Support Gasket, begin by ensuring that the mating surfaces are clean and free from debris. Use the appropriate tools to position the gasket correctly within the engine assembly. Follow the manufacturer’s guidelines for torque specifications when securing components to ensure a secure fit. It is important to handle the gasket with care to avoid damage during installation 5.

Troubleshooting Common Issues

Common problems with support gaskets include leaks or failures, which can often be traced back to improper installation or wear over time. To diagnose these issues, inspect the gasket for signs of damage or wear. If a leak is detected, the gasket may need to be replaced. Ensure that all mating surfaces are clean and that the gasket is correctly positioned to prevent future issues 6.

Maintenance Tips

Regular maintenance of the Cummins 3060538 Support Gasket is important to ensure its continued performance. Inspect the gasket during routine engine maintenance checks for any signs of wear or damage. Clean the mating surfaces as necessary to prevent contamination, which could lead to leaks. Replace the gasket according to the manufacturer’s recommendations or if any signs of failure are observed 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted name in the industry 8.

Support Gasket 3060538 Compatibility with Cummins Engines

The Support Gasket part number 3060538, manufactured by Cummins, is designed to fit a variety of Cummins engines. This gasket plays a role in maintaining the integrity of engine components by providing a seal between different parts. Below is a detailed breakdown of the engines that are compatible with this gasket:

Cummins 4B Series Engines

- 4B3.9

Cummins 6B Series Engines

- 6B5.9

Cummins 6C Series Engines

- 6C8.3

Cummins B5.9 G Series Engines

- B5.9 G

Cummins C Series Engines

- C GAS PLUS CM556

Cummins C8.3 G Series Engines

- C8.3 G

Cummins ISB Series Engines

- ISB CM550

Cummins ISC Series Engines

- ISC CM554

Cummins ISM Series Engines

- ISM CM570

Cummins K Series Engines

- K19

- K38

- K50

Cummins L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

Cummins M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

Cummins N14 Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

Cummins NH/NT Series Engines

- NH/NT 855

Cummins QSB Series Engines

- QSB5.9 44 CM550

Cummins QSK Series Engines

- QSK19 CM500

Cummins QSM Series Engines

- QSM11 CM570

This gasket is engineered to ensure a proper seal and fit across these various engine models, providing reliability and performance. It is important to verify the correct application of this gasket to maintain the engine’s operational integrity 9.

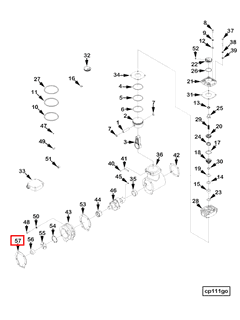

Role of Part 3060538 Support Gasket in Engine Systems

The Part 3060538 Support Gasket is integral to the efficient operation and maintenance of various engine components. Its primary function is to provide a secure and sealed connection between different parts, ensuring optimal performance and longevity of the engine system.

Integration with Compressor Systems

In systems involving the Cylinder Air (Painted) Compressor and the Cylinder Air Compressor, the Support Gasket plays a role in maintaining the integrity of the air compression process. It ensures that there are no leaks in the compressed air pathway, which is important for the efficient operation of these compressors.

Accessory Drive and Air Compressor Systems

When integrated with the Accessory Drive and the Air Compressor, the Support Gasket helps in securing the drive mechanism to the compressor. This is particularly important in systems where the Air Compressor Drive and Air Compressor Support and Drive are used, as it ensures that the drive components are firmly in place, reducing the risk of mechanical failure.

Conversion and Repair Kits

In the context of an Air Compressor Conversion Kit or an Air Compressor Kit, the Support Gasket is often included to facilitate the secure attachment of new components to the existing engine framework. Similarly, in a Repair Kit, it is used to replace worn-out gaskets, restoring the seal and efficiency of the compressor system.

Fuel Pump Compressor Assembly

In the Fuel Pump Compressor Assembly, the Support Gasket is used to ensure a tight seal between the fuel pump and the compressor. This is vital for maintaining the correct pressure and flow of fuel within the system, directly impacting the engine’s performance.

Thermostat Housing

The Support Gasket also finds its application in the Thermostat Housing. Here, it ensures that the housing is securely attached to the engine, preventing any coolant leaks and maintaining the engine’s optimal operating temperature.

EBM: Compressor

In systems labeled as EBM: Compressor, the Support Gasket is used to maintain the structural integrity and sealing of the compressor unit, ensuring efficient operation and durability.

Painted Air Compressor

For the Painted Air Compressor, the Support Gasket is essential in maintaining the aesthetic appeal while ensuring functional reliability. It secures the compressor to the engine, preventing any displacement or misalignment.

Conclusion

In summary, the Part 3060538 Support Gasket is a versatile component that enhances the functionality and reliability of various engine systems by providing essential sealing and structural support.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5504570, 2018.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Cummins Inc. Company Overview. 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5504570, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.