3944001

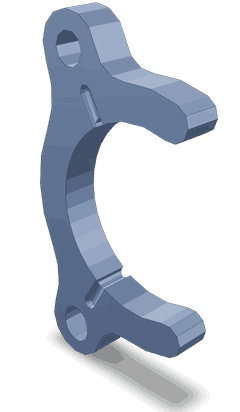

Camshaft Thrust Support

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3944001 Camshaft Thrust Support is a component designed to facilitate the smooth operation of heavy-duty truck engines. Its purpose is to manage the axial movement of the camshaft, ensuring proper alignment and reducing wear on engine components. This part plays a role in the engine cooling system by maintaining the efficiency and reliability of the engine 1.

Basic Concepts of Camshaft Thrust Support

Camshaft thrust supports are integral to the engine’s operation, providing a stable platform for the camshaft to operate within the engine block. These supports manage the axial forces that occur during engine operation, preventing excessive movement that could lead to misalignment and increased wear. The mechanics of thrust management involve absorbing and distributing these forces to maintain camshaft stability 2.

Purpose of the 3944001 Camshaft Thrust Support

The 3944001 Camshaft Thrust Support is designed to control the axial movement of the camshaft within the engine. By doing so, it helps maintain the camshaft’s alignment, which is vital for the precise operation of the valve train. This support ensures that the camshaft operates within specified tolerances, contributing to the engine’s overall performance and longevity 3.

Key Features

The 3944001 Camshaft Thrust Support is constructed from durable materials that can withstand the high stresses and temperatures within the engine environment. Its design includes features that enhance its performance, such as a smooth bearing surface to reduce friction and specialized contours to accommodate the camshaft’s movement. These attributes contribute to the support’s effectiveness in managing camshaft thrust.

Benefits

Incorporating the 3944001 Camshaft Thrust Support into an engine assembly offers several advantages. It contributes to improved engine efficiency by ensuring the camshaft operates smoothly and within design specifications. This support also reduces wear on camshaft components, leading to extended engine life. Additionally, it enhances overall engine reliability by maintaining proper camshaft alignment and reducing the risk of mechanical failures.

Installation Process

Installing the 3944001 Camshaft Thrust Support requires careful attention to detail to ensure proper setup. The process involves positioning the support within the engine block, aligning it with the camshaft, and securing it in place. It is important to follow manufacturer guidelines to avoid installation errors that could affect engine performance. Best practices include thorough cleaning of mating surfaces and verifying that all components are correctly aligned before final assembly.

Common Issues and Troubleshooting

Typical problems associated with camshaft thrust supports may include wear, misalignment, or damage due to improper installation. Troubleshooting these issues involves inspecting the support for signs of wear or damage, ensuring it is correctly aligned with the camshaft, and verifying that all installation steps were followed. Solutions may range from simple re-alignment to replacement of the support if significant wear or damage is present.

Maintenance Tips

Regular maintenance of the 3944001 Camshaft Thrust Support is important to ensure its continued performance. This includes periodic inspection for signs of wear or damage, cleaning to remove any contaminants that could affect its operation, and verifying that it remains properly aligned with the camshaft. Adhering to these maintenance practices helps prevent issues that could lead to engine inefficiencies or failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components designed to meet the demanding requirements of commercial vehicle applications.

Cummins Camshaft Thrust Support 3944001 Compatibility

The Cummins Camshaft Thrust Support part number 3944001 is designed to fit a variety of Cummins engines. This part plays a role in maintaining the integrity and performance of the camshaft system by providing necessary support and alignment. Below is a detailed overview of the engines with which this camshaft thrust support is compatible:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

ISB Series Engines

- ISB (Chrysler)

- ISB CM850

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

L Series Engines

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.5 L117

QSC Series Engines

- QSC8.3 CM2880 C102

Other Cummins Engines

- 6C8.3

- B5.6 CM2670 B152B

- QSB5.9 CM850

The camshaft thrust support 3944001 is engineered to ensure precise alignment and support for the camshafts in these engines, contributing to the overall efficiency and longevity of the engine. This part is essential for maintaining the camshaft’s position and reducing wear, ensuring smooth engine operation.

Role of Part 3944001 Camshaft Thrust Support in Engine Systems

The part 3944001 Camshaft Thrust Support is an essential component that ensures the proper functioning of several key engine systems. Its primary role is to maintain the alignment and stability of the camshaft within the engine, which is vital for the overall performance and longevity of the engine.

Integration with Camshaft and Camshaft Kit

The camshaft thrust support works in conjunction with the camshaft to prevent axial movement. This is particularly important in high-performance engines where the camshaft operates at higher speeds and under greater loads. When integrated into a camshaft kit, the thrust support ensures that the camshaft remains securely in place, allowing for precise valve timing and efficient engine operation.

Interaction with Connecting Rod and Piston

Although the camshaft thrust support does not directly interact with the connecting rod and piston, its role in stabilizing the camshaft indirectly affects the performance of these components. A stable camshaft ensures consistent valve operation, which in turn allows the piston to move smoothly within the cylinder, enhancing engine efficiency and reducing wear on the connecting rod.

Coordination with Cylinder Block Kit and Cylinder Head

In the context of a cylinder block kit or a cylinder head, the camshaft thrust support plays a supporting role by ensuring that the camshaft does not shift out of alignment. This stability is essential for maintaining the integrity of the valvetrain, which is a critical aspect of the cylinder head’s function. Proper camshaft alignment prevents undue stress on the cylinder block, contributing to the overall durability of the engine.

Influence on Fuel Injector and Fuel Manifold

While the camshaft thrust support does not directly affect the fuel injector or fuel manifold, its role in maintaining camshaft stability ensures that the engine runs smoothly. A stable camshaft leads to consistent valve operation, which in turn allows the fuel injector to deliver fuel at the optimal time. This results in better fuel efficiency and reduced emissions, enhancing the performance of the fuel manifold and the overall fuel delivery system.

Contribution to DCX Camshaft Repair and Long Block

In a DCX camshaft repair scenario, the camshaft thrust support is often replaced to ensure that the repaired camshaft operates within specified tolerances. For a long block, which includes the cylinder block, crankshaft, pistons, and camshaft, the thrust support is a key component that ensures the camshaft functions correctly within the assembled unit. This is particularly important in high-performance applications where even minor misalignments can lead to significant performance issues.

Role in Short Block and Short Block Kit

In a short block or short block kit, which typically includes the cylinder block, crankshaft, pistons, and connecting rods but excludes the cylinder head and valvetrain, the camshaft thrust support is not directly involved. However, its importance becomes evident when the cylinder head is installed, as it ensures that the camshaft operates within the designed parameters, contributing to the overall performance and reliability of the engine.

Impact on Performance Parts

For performance parts, the camshaft thrust support is often overlooked but is equally important. High-performance camshafts operate at higher speeds and under greater loads, making the thrust support a vital component for maintaining camshaft stability. This stability is essential for achieving the desired performance gains and ensuring that the engine operates reliably under demanding conditions.

Conclusion

The Cummins 3944001 Camshaft Thrust Support is a critical component in the operation of heavy-duty truck engines. By managing the axial movement of the camshaft, it ensures proper alignment and reduces wear on engine components, contributing to the engine’s efficiency and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.