This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

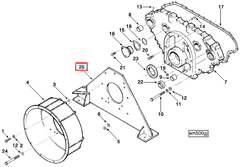

The Cummins 3060871 Front Engine Support is a component designed to enhance the operational efficiency and structural integrity of commercial truck engines. This part is integral to the engine assembly, providing necessary support and stability to the engine’s front section.

Purpose and Function

The Front Engine Support secures the engine to the truck’s frame, maintaining alignment and stability during operation. By supporting the engine’s front section, it helps distribute the engine’s weight and reduces stress on other components, contributing to the overall structural integrity and operational efficiency of the engine 1.

Key Features

The Cummins 3060871 Front Engine Support is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its performance and durability, such as precision-machined mounting surfaces and robust attachment points. These elements ensure a secure fit and reliable performance over the engine’s lifespan 2.

Benefits

Incorporating the Front Engine Support into the engine assembly offers several advantages. It improves engine stability by providing a solid mounting point, which helps reduce engine movement and vibration. This stability can lead to enhanced longevity of engine components by minimizing wear and tear. Additionally, the support contributes to a more efficient engine operation by maintaining proper alignment and reducing the likelihood of component misalignment 3.

Installation Process

Installing the Cummins 3060871 Front Engine Support requires careful attention to detail to ensure optimal performance. The process involves securing the support to the truck’s frame and connecting it to the engine. It is important to follow manufacturer guidelines for torque specifications and alignment to ensure a secure and efficient installation. Tools required may include torque wrenches and alignment tools to achieve the correct fit 4.

Maintenance and Troubleshooting

Routine maintenance of the Front Engine Support is crucial for prolonging its life and ensuring optimal engine performance. This includes regular inspections for signs of wear or damage and tightening any loose connections. Common issues may include misalignment or wear on mounting surfaces, which can be addressed by realigning the support or replacing worn components as necessary.

Compatibility and Applications

The Cummins 3060871 Front Engine Support is designed to fit specific types of commercial trucks and engine models. Its applicability varies across different truck makes and models, making it important to verify compatibility before installation. This ensures the support provides the intended benefits and integrates seamlessly with the engine assembly.

Safety Considerations

When working with the Front Engine Support, it is important to observe safety guidelines and precautions. This includes ensuring the engine is cool before beginning any work, using appropriate personal protective equipment, and following all manufacturer instructions for installation and maintenance. These precautions help ensure a safe working environment and prevent accidents.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in engine component manufacturing. With a rich history of producing reliable and efficient engine parts, Cummins has established a reputation for excellence. The company’s product range includes a variety of engine components designed to enhance the performance and durability of commercial trucks.

Front Engine Support Part 3060871 by Cummins

The Front Engine Support part 3060871 by Cummins is a critical component designed to ensure the stability and proper alignment of the engine within the vehicle. This part is engineered to fit seamlessly with various Cummins engines, providing robust support and reducing engine movement during operation.

V28 Engines

For V28 engines, the Front Engine Support part 3060871 plays a pivotal role in maintaining the structural integrity of the engine. This part is specifically designed to interface with the front section of the V28 engine, ensuring that it remains securely anchored and aligned. The support helps in distributing the engine’s weight evenly, which is crucial for the longevity and performance of the engine.

Grouping of Engines

The Front Engine Support part 3060871 is not limited to a single engine model but is compatible with a range of Cummins engines. This part is engineered to fit with multiple engine configurations, making it a versatile component in the Cummins engine lineup. Its design allows it to be used across different engine models, ensuring that it provides the necessary support and stability regardless of the specific engine variant.

The compatibility of the part with various engines highlights its importance in the overall engine assembly process. By providing a standardized support solution, Cummins ensures that the engine remains stable and operational, contributing to the overall efficiency and performance of the vehicle.

Role of Part 3060871 Front Engine Support in Engine Systems

The part 3060871 Front Engine Support is integral to the structural integrity and operational efficiency of various engine systems. It primarily serves to anchor the engine securely within the vehicle’s chassis, ensuring stability during operation.

Integration with Key Components

-

Engine Mounts: The Front Engine Support interfaces directly with the engine mounts, which are responsible for absorbing vibrations and minimizing engine movement. This connection ensures that the engine remains stable and aligned correctly within the vehicle.

-

Transmission Housing: In many engine configurations, the Front Engine Support is also connected to the transmission housing. This linkage helps in maintaining the alignment between the engine and transmission, which is essential for smooth gear shifts and overall drivetrain performance.

-

Subframe: The support is often bolted to the vehicle’s subframe, providing a robust connection point that distributes the engine’s weight and operational forces evenly across the chassis. This reduces stress on individual components and enhances the vehicle’s durability.

-

Cooling System: Proper alignment facilitated by the Front Engine Support ensures that the engine remains in the optimal position relative to the cooling system components, such as the radiator and cooling fans. This alignment is vital for efficient heat dissipation and engine temperature management.

-

Exhaust System: The support helps maintain the correct positioning of the engine, which in turn ensures that the exhaust system components, including the catalytic converter and muffler, are aligned properly. This alignment is important for efficient exhaust flow and reduced emissions.

-

Fuel System: By keeping the engine in the correct position, the Front Engine Support indirectly supports the fuel system’s components, such as the fuel lines and injectors, ensuring they operate within their designed parameters for optimal fuel delivery and combustion efficiency.

-

Electrical Components: The stable engine position provided by the Front Engine Support ensures that electrical components, such as sensors and wiring harnesses, remain securely in place. This stability is important for consistent electrical performance and reliable data transmission within the engine control unit (ECU).

Conclusion

In summary, the Cummins 3060871 Front Engine Support plays a significant role in maintaining the structural and operational integrity of various interconnected engine systems, contributing to the overall performance and reliability of the vehicle. Its design and functionality ensure that the engine remains securely anchored and aligned, which is crucial for the longevity and efficiency of the engine and the vehicle as a whole.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.