This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

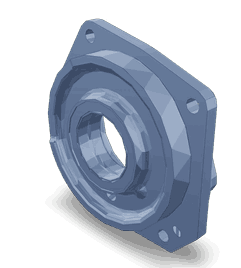

The 3007391 Hydraulic Pump Support, manufactured by Cummins, is a critical component in the hydraulic systems of commercial trucks. This part ensures the efficient operation and reliability of hydraulic systems, which are essential for various truck functions such as braking, steering, and lifting mechanisms 1.

Basic Concepts of Hydraulic Pump Support

Hydraulic systems in trucks utilize pressurized fluid to transfer power. The Hydraulic Pump Support provides structural integrity and stability to the pump, ensuring consistent performance under varying operational conditions. It maintains alignment and reduces vibrations, which are crucial for the efficient operation of the hydraulic system 2.

Purpose of Hydraulic Pump Support 3007391

The 3007391 is designed to enhance the operation of hydraulic systems by securing the hydraulic pump in place. This ensures the pump operates within its designed parameters, contributing to the overall reliability and performance of the hydraulic system. It is particularly important in systems requiring precise control and consistent power delivery 3.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions typical of commercial truck operations. The support is designed for durability, offering long-term reliability. Additionally, its design allows for easy installation and integration with the hydraulic system, minimizing downtime during maintenance or replacement.

Benefits

Incorporating the 3007391 into a truck’s hydraulic system can lead to improved system efficiency by ensuring the pump operates smoothly and consistently. This can result in enhanced performance of hydraulic applications, such as better braking or lifting capabilities. Moreover, its durability and reliability can lead to reduced maintenance needs and costs, offering a cost-effective solution for fleet operators.

Installation Considerations

When installing the 3007391, it is important to follow manufacturer guidelines to ensure proper integration with the truck’s hydraulic system. Compatibility with various truck models and systems should be verified prior to installation. Careful attention to alignment and securing the support in place is crucial to ensure optimal performance and longevity of the hydraulic pump and the overall system.

Maintenance and Troubleshooting

Routine maintenance of the 3007391 involves checking for signs of wear or damage and ensuring it remains securely fastened. Common issues may include misalignment or wear, which can affect the performance of the hydraulic system. Regular inspections and timely replacements or repairs can help prevent more significant problems and ensure the continued efficient operation of the truck’s hydraulic systems.

Safety Considerations

Handling and working with the 3007391 requires adherence to safety guidelines. This includes ensuring the truck is properly secured and the hydraulic system is depressurized before beginning any work. Personal protective equipment should be worn, and all manufacturer safety instructions should be followed to prevent accidents or injuries during installation, maintenance, or operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Their product range is designed to meet the demanding needs of commercial operations, offering solutions that enhance performance, efficiency, and reliability.

Compatibility with Cummins Engines

The Hydraulic Pump Support 3007391 is designed to fit a variety of Cummins engines, ensuring the hydraulic pump operates smoothly and efficiently. It is compatible with the following engine series:

- K19 Series: K19, QSK19 CM2350 K105, QSK19 CM2350 K114

- 6C8.3 Series: 6C8.3

- KTA19 Series: KTA19 GC CM558

- QSK19 Series: QSK19 CM500, QSK19 CM850 MCRS

By ensuring that the Hydraulic Pump Support 3007391 is correctly installed, users can maintain the integrity and efficiency of their hydraulic systems, contributing to the overall performance and longevity of their engines.

Role of Hydraulic Pump Support in Engine Systems

The Hydraulic Pump Support 3007391 is an integral component that ensures the efficient operation and stability of various hydraulic systems within an engine. This support is designed to integrate seamlessly with multiple engine components, enhancing their functionality and reliability.

- Integration with Drive Systems: Provides a stable mounting platform for the accessory drive and auxiliary pump drive, ensuring proper alignment and reducing vibrations.

- Enhancing Auxiliary Systems: Maintains the alignment and operational stability of the auxiliary pump, crucial for additional hydraulic pressure functions.

- Supporting Front Gear Train Accessory: Ensures the accessory remains securely in place, maintaining precise gear alignment for efficient power transfer.

- Filtration and Hydraulic Systems: Holds the full flow oil filter and front hydraulic pump firmly in place, maintaining the integrity of the filtration process and hydraulic pump operation.

- Hydraulic Drive Kit and Pump Drive: Maintains structural integrity and proper alignment of the hydraulic drive kit and pump drive, essential for efficient hydraulic power transfer.

- Scavenge Pump and Auxiliary Transfer: Provides a stable mounting solution for the K19 scavenge pump and auxiliary transfer pump & drive, ensuring efficient operation and reducing the risk of misalignment.

Conclusion

The Hydraulic Pump Support 3007391 by Cummins plays a vital role in the stability and efficiency of various engine systems. By providing a secure and aligned mounting platform for critical hydraulic and drive components, it enhances the overall performance and reliability of the engine. Proper installation, maintenance, and adherence to safety guidelines are essential to maximize the benefits of this part.

-

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.