This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

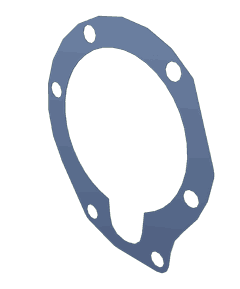

The 117077 Support Gasket, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and engines known for their reliability and performance. This Cummins part is specifically engineered to maintain the integrity of various engine components by providing a seal that prevents leaks and ensures efficient operation. Support gaskets are vital in heavy-duty vehicles, where the demands on engine components are significant, and the prevention of leaks can lead to improved performance and longevity of the engine 1.

Function and Operation

The 117077 functions by creating a seal between mating surfaces within the truck’s engine or component system. This seal is essential for maintaining the integrity of the system by preventing the escape of fluids or gases that could compromise engine performance. The gasket is designed to withstand various operating conditions, including high temperatures and pressures, ensuring a consistent seal over time. Its operation is straightforward yet vital: it fills the gap between surfaces, adapting to irregularities and maintaining a seal under dynamic conditions 2.

Key Features

The 117077 boasts several key features that enhance its performance and durability. It is composed of materials selected for their ability to withstand the harsh conditions within a commercial truck engine. The design specifications of the gasket ensure it fits precisely within the engine’s components, providing a reliable seal. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its effectiveness in demanding environments 3.

Benefits of Using the 117077 Support Gasket

Utilizing the 117077 offers several advantages. It contributes to improved engine efficiency by ensuring that fluids and gases remain within their intended paths, reducing the risk of leaks that could lead to performance issues. The gasket’s durability and reliability also enhance the longevity of connected components, as it prevents wear and damage that could result from leaks. Furthermore, the reduction in leaks can lead to fewer maintenance requirements and lower operating costs over time.

Installation Guidelines

Proper installation of the 117077 is crucial for its effectiveness. Before installation, ensure that the mating surfaces are clean and free of any debris that could compromise the seal. The installation process involves positioning the gasket between the surfaces it is designed to seal, followed by securing the components in place. Tools required may include torque wrenches to ensure proper tightening without over-tightening, which could damage the gasket. Best practices include checking the gasket for proper seating after initial installation and before final tightening.

Maintenance and Troubleshooting

Maintaining the 117077 involves regular inspections for signs of wear or damage. Common issues with support gaskets include hardening, cracking, or displacement, which can lead to leaks. Troubleshooting these issues may involve replacing the gasket or addressing any underlying causes, such as misalignment of components or excessive vibration. Regular maintenance can help identify potential issues before they lead to significant problems.

Compatibility and Applications

The 117077 is designed for specific applications within the commercial truck industry. It is compatible with certain Cummins engines and may be suited for particular models or series of trucks. Ensuring compatibility is crucial for optimal performance and to avoid potential issues arising from incorrect installation.

Safety Considerations

When handling and installing the 117077, it is important to follow safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against any potential hazards. Safe handling practices also involve ensuring that the work area is clean and free of any hazards that could lead to accidents.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Role of Part 117077 Support Gasket in Engine Systems

The Part 117077 is an essential component in ensuring the efficient operation and longevity of various engine systems. Its primary function is to provide a reliable seal between different engine components, preventing leaks and maintaining the integrity of the system.

Integration with Cylinder Air Compressor

In a cylinder air compressor, the Support Gasket is positioned between the compressor housing and the cylinder assembly. This placement is vital for maintaining the airtight seal necessary for the compressor to function effectively. By preventing air leaks, the gasket ensures that the compressor can achieve and maintain the required pressure levels, which is fundamental for its performance.

Role in Compressor Crankcase

Within the compressor crankcase, the Support Gasket serves to seal the connection between the crankcase and other adjacent components, such as the cylinder or the compressor body. This seal is important for containing the lubricants and preventing contaminants from entering the crankcase, thereby protecting the internal components from wear and damage.

Use in Compressor Gasket Set

When included in a compressor gasket set, the Support Gasket works alongside other gaskets to create a comprehensive sealing solution. This set typically includes gaskets for various joints and connections within the compressor. The Support Gasket’s role is to ensure that these critical connections remain sealed, contributing to the overall efficiency and reliability of the compressor.

Function in Engine Gasket Set

In an engine gasket set, the Support Gasket is often used to seal the connections between the engine block, cylinder head, and other critical components. This ensures that coolant, oil, and combustion gases remain contained within their respective pathways, which is essential for the engine’s thermal management and performance.

Application in PDC (Positive Displacement Compressor)

For PDCs, the Support Gasket is integral in sealing the various stages of compression. It ensures that each stage operates independently without cross-contamination or leakage, which is vital for maintaining the compressor’s efficiency and output pressure.

Importance in Lower Engine Gasket Set

In a lower engine gasket set, the Support Gasket is used to seal the lower portion of the engine, including the oil pan, front cover, and rear main seal. This helps in maintaining oil integrity and preventing leaks, which is essential for lubrication and cooling of the engine’s moving parts.

Contribution to Set Gasket

When part of a set gasket, the Support Gasket complements other gaskets to provide a comprehensive sealing solution across the engine or compressor. This set typically includes gaskets for various joints and connections, and the Support Gasket plays a key role in ensuring that these critical connections remain sealed, contributing to the overall efficiency and reliability of the system.

Conclusion

The 117077 Support Gasket is a critical component in the maintenance and efficiency of commercial truck engines. Its role in preventing leaks, ensuring proper sealing between components, and contributing to the overall performance and longevity of the engine cannot be overstated. Proper installation, regular maintenance, and understanding its applications are key to maximizing the benefits of this Cummins part.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Bonnick, Allan and Newbold, Derek. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.