5282508

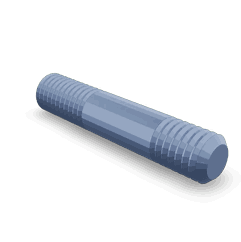

Double End Plain Stud

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Double End Plain Stud 5282508, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins is known for its high-quality components that enhance the performance and reliability of heavy-duty vehicles. This part is significant in truck operations due to its role in securely connecting various components within the truck’s mechanical system.

Basic Concepts

A Double End Plain Stud is a type of fastener characterized by having threads on both ends, allowing it to be screwed into two separate components to hold them together. The construction of this Cummins part typically involves high-strength materials to ensure durability and reliability under the demanding conditions of commercial truck operations. It functions by providing a strong, secure connection between components, which is essential for the overall integrity and performance of the truck’s mechanical system 1.

Purpose and Role

The Double End Plain Stud 5282508 serves a vital function in truck operations by connecting and securing various components within the truck’s mechanical system. Its design allows for a robust connection that can withstand the vibrations, stresses, and environmental conditions encountered in commercial truck applications. This stud plays a role in maintaining the structural integrity of the truck, ensuring that components remain securely fastened during operation 2.

Key Features

The Double End Plain Stud 5282508 is distinguished by several key features that enhance its performance and durability. These include its material composition, which is typically a high-strength alloy designed to resist wear and corrosion. The thread type is another critical feature, ensuring a secure fit and easy installation. Additionally, the design specifications of the stud, such as its length and diameter, are tailored to meet the specific requirements of commercial truck applications 3.

Benefits

The use of the Double End Plain Stud 5282508 offers several benefits in commercial truck applications. Its high-strength material composition and precise thread type contribute to improved reliability and durability. The stud’s design also facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, its resistance to wear and corrosion ensures longevity, even under the harsh conditions typical of commercial truck operations 4.

Installation and Usage

Proper installation of the Double End Plain Stud 5282508 is crucial for ensuring a secure fit and optimal performance. Guidelines for installation include using the recommended torque settings to achieve the correct tension without overtightening, which could damage the stud or the components it connects. Best practices for installation also involve inspecting the stud and the components for any signs of damage or wear before assembly to ensure a secure and reliable connection.

Maintenance and Troubleshooting

Maintaining the Double End Plain Stud 5282508 involves regular inspection for signs of wear, corrosion, or damage. Common issues may include loosening of the stud, which can be addressed by retightening to the recommended torque settings. In cases of significant wear or damage, replacement of the stud may be necessary to ensure the continued reliability and safety of the truck’s mechanical system. Troubleshooting methods should focus on identifying the root cause of any issues to prevent recurrence.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for heavy-duty vehicles. The company’s reputation is built on its commitment to innovation, quality, and reliability. Cummins’ products, including the Double End Plain Stud 5282508, are designed to meet the rigorous demands of commercial truck applications, ensuring optimal performance and durability. The company’s dedication to excellence is reflected in its wide range of automotive components, which are trusted by professionals in the industry.

Cummins Double End Plain Stud 5282508 in Engine Applications

The Cummins Double End Plain Stud, part number 5282508, is a critical component in various Cummins engine models. This part is designed to provide robust and reliable fastening in engine assemblies, ensuring structural integrity and operational efficiency.

QSB3.3 CM2250 EC Engines

In the QSB3.3 CM2250 EC engines, the Double End Plain Stud 5282508 is utilized in several key areas. It is often employed in the engine’s mounting system, where it secures the engine to the vehicle chassis or other engine components. This stud’s design allows for secure attachment from both ends, providing a stable and durable connection that can withstand the stresses of engine operation.

Grouping of Engines

The Double End Plain Stud 5282508 is also compatible with other Cummins engine models within the same series. These engines share similar design principles and operational requirements, making the stud a versatile component across multiple engine types. Its application extends to various mounting points and structural connections within these engines, ensuring consistent performance and reliability.

The use of the Double End Plain Stud in these engines highlights its importance in maintaining the integrity of engine assemblies. Its design and material properties make it suitable for high-stress environments, ensuring that the engine operates smoothly and efficiently.

Role of Part 5282508 Double End Plain Stud in Engine Systems

The Part 5282508 Double End Plain Stud is an essential component in various engine systems, facilitating secure connections and ensuring the integrity of the assembly.

In hardware kits, this stud is often utilized to connect different parts securely. Its double-ended design allows for a robust connection on both sides, which is particularly beneficial in high-stress environments where vibrations and thermal expansion are common. This ensures that components remain firmly in place, reducing the risk of mechanical failure.

Within recirculation systems, the Double End Plain Stud plays a significant role in maintaining the structural integrity of the assembly. It is commonly used to secure recirculation valves and other components, ensuring that the system operates efficiently without leaks or malfunctions. The stud’s design helps in withstanding the pressure variations and temperature changes typical in recirculation systems.

In exhaust systems, the Double End Plain Stud is employed to connect exhaust manifolds, catalytic converters, and other components. Its ability to provide a strong, reliable connection is vital in an environment where high temperatures and corrosive gases are present. This ensures that the exhaust system remains sealed, preventing harmful emissions from escaping and maintaining the efficiency of the engine.

Conclusion

The Double End Plain Stud 5282508 by Cummins is a critical component in commercial truck and engine applications. Its design, material properties, and precise thread type contribute to its reliability, durability, and ease of installation. Regular maintenance and proper installation practices are essential to ensure the continued performance and safety of the truck’s mechanical system. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it a trusted component in the automotive industry.

-

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.