This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3423094 Double End Plain Stud is a component manufactured by Cummins, a well-established name in the commercial truck industry. This stud is specifically designed for use in commercial trucks, where it plays a role in various mechanical assemblies. Understanding its function and application is vital for maintaining the efficiency and reliability of truck operations.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a type of fastener characterized by having threads on both ends and no head. It is commonly used in mechanical assemblies where a traditional bolt and nut arrangement is impractical. The stud is inserted through holes in the components being joined and secured with nuts on each end. This design allows for more precise alignment and distribution of clamping force, which is particularly beneficial in high-stress applications 1.

Purpose of the 3423094 Double End Plain Stud in Truck Operation

In the context of commercial trucks, the 3423094 Double End Plain Stud serves several functions. It is often used in engine assemblies, transmission systems, and other critical areas where strong, reliable fastening is required. The stud helps in maintaining the integrity of these assemblies under varying operational conditions, contributing to the overall durability and performance of the truck 2.

Key Features

The 3423094 Double End Plain Stud is crafted from high-quality materials, ensuring durability and resistance to wear and corrosion. Its thread specifications are designed to provide a secure fit, reducing the likelihood of loosening over time. The stud’s design is optimized for ease of installation and removal, which is crucial in maintenance scenarios 3.

Benefits

The use of the 3423094 Double End Plain Stud offers several advantages. Its robust construction contributes to improved reliability in truck operations. The design of the stud also facilitates easier installation, which can lead to time savings during maintenance procedures. Over time, these factors can result in cost savings for fleet operators.

Installation Process

Installing the 3423094 Double End Plain Stud involves several steps. First, the stud is aligned with the holes in the components it will join. It is then inserted and secured with nuts on each end. Torque specifications provided by Cummins should be followed to ensure the correct clamping force is applied. Proper tools, such as torque wrenches, are necessary for this process.

Troubleshooting Common Issues

Common issues with Double End Plain Studs can include loosening over time or damage due to corrosion. Regular inspections can help identify these problems early. If a stud is found to be loose, it should be re-torqued to the manufacturer’s specifications. In cases of corrosion, the stud may need to be replaced to ensure the integrity of the assembly.

Maintenance Tips

To ensure the longevity and optimal performance of the 3423094 Double End Plain Stud, regular maintenance is recommended. This includes periodic inspections for signs of wear or corrosion. Cleaning the stud and its surrounding area can prevent the buildup of contaminants that may lead to corrosion. Following the manufacturer’s guidelines for torque and maintenance intervals is also important.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Double End Plain Stud 3423094 Compatibility

The Cummins Double End Plain Stud, part number 3423094, is a critical component designed to fit seamlessly within various engine models. This part is engineered to ensure reliable performance and durability across a range of applications.

QSV81G and QSV91G Engines

The Double End Plain Stud 3423094 is compatible with both the QSV81G and QSV91G engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The stud’s precision-engineered design ensures it fits perfectly within the specified tolerances of these engines, providing a secure connection that can withstand the rigors of continuous operation.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the Double End Plain Stud 3423094 is also a perfect fit. This engine model is often used in demanding environments where reliability and performance are paramount. The stud’s compatibility with the QSW/QSV82 ensures that it can handle the stresses and strains of these demanding conditions, maintaining its integrity and functionality over time.

QSW73 Engine

The QSW73 engine is another model that benefits from the use of the Double End Plain Stud 3423094. This engine is designed for applications that require a balance of power and efficiency. The stud’s design ensures it can fit precisely within the QSW73’s specifications, providing a reliable connection that supports the engine’s performance and longevity.

By ensuring compatibility with these various engine models, the Double End Plain Stud 3423094 from Cummins offers a versatile solution for maintaining and repairing these engines. Its precision engineering and robust design make it an essential component for achieving optimal performance and reliability.

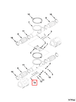

Role of Part 3423094 Double End Plain Stud in Engine Systems

The Double End Plain Stud, identified by part number 3423094, serves as a pivotal component in the assembly and support of various engine systems. Its primary function is to provide a secure and reliable connection between different engine components, ensuring the integrity and efficiency of the engine’s operation.

In the Connection Assembly Exhaust, the Double End Plain Stud is utilized to fasten the exhaust components securely. This ensures that the exhaust gases are directed efficiently away from the engine, minimizing leaks and maximizing performance.

Within the Exhaust Assembly Manifold, this stud plays a significant role in attaching the manifold to the engine block. This connection is essential for the proper distribution of exhaust gases from the cylinders to the exhaust system, enhancing the engine’s overall efficiency.

The Exhaust Manifold itself relies on the Double End Plain Stud to maintain a tight seal with the engine. This is vital for preventing exhaust leaks, which can lead to decreased engine performance and increased emissions.

In the Exhaust Manifold Assembly Support, the stud is employed to reinforce the structural integrity of the manifold. This support is necessary to withstand the high temperatures and pressures generated during engine operation, ensuring longevity and reliability.

Lastly, in the broader context of the Manifold and its interaction with the exhaust system, the Double End Plain Stud ensures that all connections are robust and secure. This is fundamental for the manifold’s role in collecting exhaust gases from the engine’s cylinders and directing them into the exhaust system.

Overall, the Double End Plain Stud, part 3423094, is integral to the secure and efficient operation of various engine components, particularly within the exhaust system. Its role in maintaining connections and supporting structural integrity is essential for the engine’s performance and durability.

Conclusion

The 3423094 Double End Plain Stud is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its robust design, ease of installation, and compatibility with multiple engine models make it an invaluable part for ensuring the reliability and efficiency of truck operations. Regular maintenance and adherence to manufacturer guidelines are essential for maximizing the lifespan and performance of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

QST30 Power Generation Interface, CM552 and CM850 Electronic Control System, Bulletin Number 4021674, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.