This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

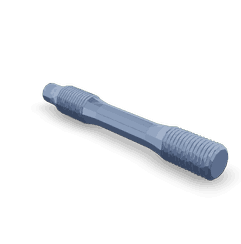

The Cummins 3420607 Stud is a specialized component designed for use in commercial truck operations. It serves a specific function within the truck’s engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help fleet operators and technicians maintain and optimize truck performance.

Basic Concepts of Studs

A stud is a threaded fastener with external male threads that is used in mechanical assemblies to secure components together. Unlike bolts, which have a head on one end, studs pass completely through the components being joined and are typically held in place with nuts on each end. In the automotive industry, studs are commonly used in applications where repeated disassembly and reassembly are required, or where high tensile strength and resistance to vibration are necessary 1.

Purpose of the 3420607 Stud

This Cummins part plays a role in securing critical components within the truck’s engine system. It is specifically designed to withstand the high stresses and vibrations encountered in commercial truck operations. This stud is utilized in areas where maintaining a secure and stable connection is vital for the engine’s performance and durability.

Key Features

The 3420607 Stud is engineered with several key features to enhance its performance and durability. It is typically made from high-strength alloy steel, which provides excellent resistance to wear and corrosion. The stud features a fine thread pitch, which allows for precise adjustments and secure fastening. Additionally, it may include unique design elements such as a rolled thread, which increases the stud’s tensile strength and fatigue resistance 2.

Benefits

Using the 3420607 Stud offers several advantages for fleet operators. Its high-strength material and precise threading contribute to improved reliability and performance. The stud’s design helps to ensure a secure connection, reducing the risk of component failure. Additionally, the durability of the stud can lead to potential cost savings by minimizing the need for frequent replacements and repairs.

Installation Process

Proper installation of the 3420607 Stud is crucial for ensuring its effectiveness and longevity. The installation process typically involves the following steps:

- Ensure the mating surfaces are clean and free of debris.

- Align the stud with the designated hole in the component.

- Thread the stud through the hole and secure it with a nut on the opposite side.

- Tighten the nut to the specified torque using a torque wrench to ensure proper tension without over-tightening.

Troubleshooting and Maintenance

Common issues with the 3420607 Stud may include loosening due to vibration, corrosion, or wear. Regular inspection and maintenance can help identify and address these issues. Diagnostic tips include checking for signs of corrosion, ensuring the stud is properly torqued, and verifying that the mating surfaces remain clean and undamaged. Maintenance practices should include periodic re-torqueing and inspection for wear or damage 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicle operators, ensuring reliability and performance in various applications.

Compatibility with Engine Models

The 3420607 Stud is designed to be compatible with several engine models, ensuring a secure and reliable fit across different applications. Here’s a detailed look at its compatibility with the specified engines:

- QSV81G and QSV91G Engines: The stud is engineered to fit seamlessly with these engines, known for their robust performance and reliability.

- QSW/QSV82 Engine: This engine also integrates the stud effectively, ensuring it can withstand operational stresses and maintain the integrity of the engine’s structure.

- QSW27 and QSW36 Engines: For these engines, the stud is an essential component, providing stability and support to the engine’s components.

- QSW73 Engine: This engine utilizes the stud, ensuring it can handle the specific demands of this engine model, contributing to its overall performance and longevity.

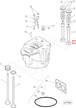

Role of Part 3420607 Stud in Engine Systems

The 3420607 Stud is integral to the secure and efficient operation of various engine components. Its primary function is to provide a robust connection point, ensuring that components remain firmly in place under the high stresses and temperatures of engine operation.

In the Assembly with Valves Head, the Stud maintains the structural integrity of the assembly by securing the head to the cylinder block, ensuring a tight seal that is essential for proper combustion and valve operation.

Within the Camshaft system, the Stud anchors the camshaft in place, which is vital for the precise timing of valve operation, fundamental to engine performance and efficiency.

For Camshaft Mounting, the Stud ensures that the camshaft is correctly positioned and aligned, critical for the smooth operation of the valve train and the overall engine timing.

In the Connecting Rod and Piston assembly, the Stud secures the connecting rod to the crankshaft, essential for transferring the force generated by the piston’s movement to the crankshaft, thereby converting linear motion into rotational motion.

The Cylinder Assembly Head relies on the Stud to maintain the seal between the cylinder head and the block, necessary to contain the combustion process within the cylinder, ensuring efficient engine operation.

In the Cylinder Head and Cylinder Sub-Assembly Head, the Stud secures various components, ensuring they remain in the correct position under the high pressures and temperatures of combustion.

The Head, Cylinder, and Head Assembly with Valves utilize the Stud to maintain the structural integrity and sealing of the combustion chamber.

In the Head Cylinder Assembly and Head Cylinder Sub-Assembly, the Stud ensures that all components are correctly aligned and sealed, essential for efficient combustion and engine performance.

The Head Gas Cylinder Assembly uses the Stud to secure the gas cylinder to the head, ensuring a tight seal that is necessary for the efficient operation of the engine.

In an Overhaul Kit, the Stud is often included to replace worn or damaged studs, ensuring that the engine can be restored to its original performance levels.

Overall, the 3420607 Stud is a fundamental component in ensuring the secure and efficient operation of various engine systems, contributing to the overall performance and reliability of the engine.

Conclusion

The Cummins 3420607 Stud is a critical component in commercial truck engine systems, designed to withstand high stresses and vibrations. Its key features, including high-strength alloy steel and precise threading, enhance performance and durability. Proper installation and maintenance are essential for maximizing its effectiveness and longevity. Understanding the role and benefits of this stud can help fleet operators and technicians maintain and optimize truck performance.

-

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.