This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3336552 Double End Plain Stud is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is specifically designed for use in commercial trucks, where it contributes to the reliable operation of various engine and component assemblies.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a type of fastener characterized by having threaded sections on both ends and a plain, unthreaded section in the middle. This design allows it to be used in applications where a traditional bolt and nut combination may not be feasible. In mechanical systems, these studs provide a secure and stable connection between components, facilitating the assembly and disassembly of parts without the need for additional fasteners 1.

Purpose of the 3336552 Double End Plain Stud in Truck Operation

In the operation of commercial trucks, this Cummins part plays a role by securing various engine components and assemblies. It is commonly used in scenarios where high tensile strength and resistance to vibration are required. The stud helps maintain the integrity of engine assemblies, ensuring that parts remain firmly in place under the dynamic conditions experienced during truck operation.

Key Features

This part is constructed from high-quality materials, typically featuring a robust thread specification that ensures a strong and reliable connection. Its design includes precision-machined threads and a smooth central section, which allows for easy installation and removal while providing a secure fit. The material composition is chosen to withstand the harsh environments and high stresses encountered in commercial truck applications 2.

Benefits of Using the 3336552 Double End Plain Stud

Utilizing this part in truck applications offers several advantages. Its durable construction contributes to the longevity of engine assemblies, while its reliable performance helps prevent component failure. The stud’s design enhances the overall efficiency of truck operations by ensuring that connections remain secure, even under demanding conditions.

Installation Considerations

Proper installation of the 3336552 Double End Plain Stud is vital to ensure optimal performance and longevity. It is recommended to follow manufacturer guidelines for torque specifications and to use the appropriate tools to avoid damage to the threads. Ensuring that the surfaces to be joined are clean and free from debris will also contribute to a secure and lasting connection.

Troubleshooting Common Issues

Common problems associated with Double End Plain Studs may include thread damage, stud loosening, or corrosion. To address these issues, it is important to regularly inspect the studs for signs of wear or damage. If thread damage is detected, the stud should be replaced to prevent further complications. Applying an appropriate anti-seize compound can help prevent corrosion and facilitate future removal.

Maintenance Tips

Regular maintenance of the 3336552 Double End Plain Stud is key to preventing failures and extending its service life. This includes periodic checks for signs of wear, ensuring that the stud remains securely fastened, and cleaning the stud and surrounding areas to prevent the accumulation of debris. Following these maintenance practices will help maintain the integrity of the truck’s engine assemblies.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted partner for commercial truck operators worldwide.

Compatibility of Double End Plain Stud Part 3336552 with Cummins Engines

The Double End Plain Stud part number 3336552, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is crucial for maintaining the structural integrity and operational efficiency of these engines. Here is a detailed look at how this part fits with specific Cummins engines:

QSV81G and QSV91G Engines

The Double End Plain Stud part 3336552 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The stud is engineered to withstand the high stresses and torques generated by these engines, ensuring a secure fit and long-lasting performance.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the Double End Plain Stud part 3336552 is an ideal fit. These engines are part of Cummins’ range of medium-duty engines, offering a balance of power and efficiency. The stud’s design ensures it can handle the specific demands of these engines, providing a reliable connection in critical areas.

QSW73 Engine

The QSW73 engine also benefits from the use of the Double End Plain Stud part 3336552. This engine is typically used in applications requiring a balance of power and fuel efficiency. The stud’s precision engineering ensures it fits perfectly, contributing to the engine’s overall performance and longevity.

QSZ90 Engine

Lastly, the QSZ90 engine is another model that can utilize the Double End Plain Stud part 3336552. This engine is designed for high-performance applications, and the stud’s robust construction ensures it can handle the demanding conditions these engines operate under.

Each of these engines, while differing in specific applications and performance characteristics, shares a common requirement for high-quality, reliable components like the Double End Plain Stud part 3336552. This part’s compatibility across these models underscores its versatility and importance in maintaining engine integrity and performance.

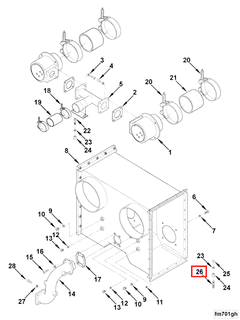

Role of Part 3336552 Double End Plain Stud in Engine Systems

In the intricate architecture of engine systems, the Double End Plain Stud (part 3336552) serves as a fundamental connector, ensuring the secure assembly and operation of various components. This stud is integral in maintaining the structural integrity and functional efficiency of the engine.

Air Assembly Cleaner

Within the air assembly cleaner, the Double End Plain Stud is employed to fasten the cleaner housing to the engine block. This secure attachment is essential for maintaining the airtight seal required for optimal air filtration and intake.

Air Fuel Assembly Mixer and Assembly Mixer Air Fuel

In both the air fuel assembly mixer and the assembly mixer air fuel, the stud plays a pivotal role in connecting the mixer housing to the fuel control module. This connection is vital for the precise mixing of air and fuel, a process that is fundamental to the combustion efficiency of the engine.

Cleaner, Air, and Gas Modules

Across various gas modules, including those operating at pressures of 1.25 bar, 1.8 bar, and 3 bar, the Double End Plain Stud is utilized to secure the gas module housing to the pump drive assembly. This ensures that the gas modules are firmly in place, allowing for stable and consistent gas flow into the engine.

Pump Drive and Fuel Control Module

The stud is also instrumental in attaching the pump drive to the fuel control module. This connection is key to the efficient transfer of mechanical energy from the pump drive to the fuel control system, ensuring that fuel is delivered to the engine under the correct pressure and volume.

Gas Module P=3bar Gas

Specifically, in the gas module operating at 3 bar, the Double End Plain Stud is used to secure the module to the engine’s fuel system. This high-pressure application demands a robust and reliable connection, which the stud provides, contributing to the overall performance and safety of the engine system.

Conclusion

In summary, the Double End Plain Stud (part 3336552) is a versatile and essential component in the assembly and operation of various engine systems. Its role in securing critical connections ensures the efficient and safe functioning of the engine, highlighting its importance in engine design and maintenance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.