This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3255484 Stud is a specialized fastener designed for use in heavy-duty truck operations. It serves a pivotal role in ensuring the secure attachment of various components within the truck’s engine and chassis systems. This part is engineered to withstand the rigorous demands of heavy-duty applications, providing reliable performance and durability.

Basic Concepts of Studs

A stud is a threaded fastener with external threads on both ends. It is used in mechanical assemblies to provide a secure connection between two or more components. Unlike bolts, which have a head on one end, studs extend through the components being joined and are typically secured with nuts on both ends. In the automotive industry, studs are commonly used in applications where repeated disassembly and reassembly are required, or where high tensile strength is necessary 1.

Purpose of the Cummins 3255484 Stud

The Cummins 3255484 Stud plays a specific role in the operation of heavy-duty trucks. It is primarily used in applications where high tensile strength and durability are required, such as in the engine block, cylinder head, and other critical components. This part helps maintain structural integrity by providing a robust connection that can withstand the extreme forces and vibrations encountered in heavy-duty operations. Its application areas include securing engine components, chassis parts, and other critical assemblies.

Key Features

The Cummins 3255484 Stud is characterized by several key features that enhance its performance and durability. It is typically made from high-strength alloy steel, which provides excellent resistance to wear and corrosion. The stud has a specific thread size and length designed to meet the requirements of its intended application. Additionally, it may feature unique design elements such as a rolled thread, which increases strength and fatigue resistance, and a corrosion-resistant coating to enhance longevity 2.

Benefits

The Cummins 3255484 Stud offers several advantages over other fastening methods. Its high-strength material composition and precise manufacturing ensure improved reliability and enhanced load-bearing capacity. The stud’s design allows for secure fastening, reducing the risk of loosening over time. Additionally, its corrosion-resistant properties contribute to its longevity, making it a cost-effective solution for heavy-duty applications.

Installation Process

Proper installation of the Cummins 3255484 Stud is crucial to ensure secure fastening and optimal performance. The installation process involves several steps:

- Preparation: Ensure the mating surfaces are clean and free of debris.

- Insertion: Thread the stud through the designated holes in the components being joined.

- Securing: Place nuts on both ends of the stud and tighten them to the specified torque using a torque wrench. It is important to follow the manufacturer’s torque specifications to avoid over-tightening or under-tightening.

- Inspection: Verify that the stud is securely fastened and that there is no excessive movement.

Troubleshooting and Maintenance

Common issues that may arise with studs include corrosion, stripping, or loosening. To address these issues:

- Corrosion: Regularly inspect studs for signs of corrosion and clean them as necessary. Applying a corrosion-resistant coating can help prevent future issues.

- Stripping: Ensure that the correct tools and techniques are used during installation to avoid stripping the threads.

- Loosening: Periodically check the torque of the nuts securing the stud to ensure they remain tight. Re-torque as needed according to the manufacturer’s specifications.

Safety Considerations

When working with studs, it is important to follow safety practices to ensure personal protection and proper installation:

- Handling: Use appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against injury.

- Torque Specifications: Adhere to the manufacturer’s torque specifications to avoid over-tightening, which can damage the stud or the components being joined.

- Tools: Use the correct tools, such as a torque wrench, to ensure accurate tightening.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the heavy-duty truck industry for producing reliable and high-performance products. The company’s commitment to innovation and quality has made it a trusted name among fleet operators and maintenance professionals 3.

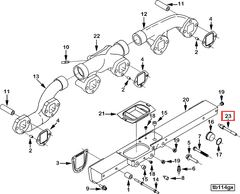

Cummins Stud Part 3255484 in N14 CELECT PLUS Engines

The Cummins Stud part number 3255484 is a critical component in the N14 CELECT PLUS engine. This part is integral to the engine’s structural integrity and operational efficiency, ensuring that various parts are securely fastened and aligned.

In the N14 CELECT PLUS engine, the stud is typically used in areas where high-strength fastening is required. This includes securing engine blocks, cylinder heads, and other critical components. The precision engineering of the stud ensures that it can withstand the extreme conditions within the engine, such as high temperatures and pressures.

The stud’s design allows for easy installation and removal, which is crucial during maintenance and repair operations. Its robust construction ensures longevity and reliability, reducing the likelihood of failure under operational stress.

While the N14 CELECT PLUS engine is not the only engine that utilizes the Cummins Stud part number 3255484, it is a common application. This part is also used in other Cummins engines where similar fastening requirements are present. The versatility and reliability of this stud make it a preferred choice for various engine models within the Cummins lineup.

Role of Part 3255484 Stud in Engine Systems

Part 3255484 Stud is integral to the secure and efficient operation of various engine components. In the context of an arrangement, this stud ensures that components are held in precise alignment, which is essential for the overall structural integrity and performance of the engine. Proper alignment facilitated by the stud allows for optimal force distribution across the engine, reducing the likelihood of mechanical stress and potential failure.

In turbocharger systems, the stud plays a significant role in maintaining the secure attachment of the turbocharger to the engine block or manifold. This secure attachment is vital for withstanding the high pressures and temperatures generated during operation. The stud ensures that the turbocharger remains firmly in place, allowing it to function efficiently without the risk of detachment or misalignment, which could lead to performance issues or damage.

Conclusion

The Cummins 3255484 Stud is a critical component in heavy-duty truck operations, providing high tensile strength, durability, and reliable performance. Its key features, including high-strength alloy steel construction, rolled threads, and corrosion-resistant coatings, enhance its functionality and longevity. Proper installation, regular maintenance, and adherence to safety practices are essential to ensure the optimal performance and longevity of this part. As a trusted component in Cummins engines, the 3255484 Stud plays a vital role in maintaining the structural integrity and efficiency of engine systems.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.