This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3680696 Check Valve Plunger Stop is a component designed to enhance the operation of commercial trucks. Its purpose is to regulate the flow of fluid within the system, ensuring that it moves in the correct direction and at the appropriate pressure. This part contributes to the overall efficiency and reliability of the truck’s hydraulic or fuel system 1.

Basic Concepts of Check Valve Plunger Stop

Check valve plunger stops function by allowing fluid to flow in one direction while preventing reverse flow. This is achieved through a plunger mechanism that opens and closes in response to fluid pressure. The integrity of the system is maintained by ensuring that fluid does not flow backward, which could lead to inefficiencies or damage to other components 2. Understanding these principles is fundamental to grasping the role of the 3680696 Check Valve Plunger Stop in a truck’s operation.

Role of the 3680696 Check Valve Plunger Stop in Truck Operation

The 3680696 Check Valve Plunger Stop plays a specific role in the operation of a truck by regulating the flow of fluid within the system. It interacts with other components such as pumps and actuators, ensuring that fluid is delivered at the correct pressure and in the right direction. This contributes to the overall performance of the truck by maintaining system efficiency and preventing potential issues that could arise from incorrect fluid flow 3.

Key Features

The 3680696 Check Valve Plunger Stop is characterized by its robust design and the materials used in its construction. It is built to withstand the pressures and conditions typical of commercial truck operations. Unique features such as its precise plunger mechanism and durable housing enhance its functionality, ensuring reliable performance over time.

Benefits

Using the 3680696 Check Valve Plunger Stop offers several benefits. It contributes to improved system efficiency by ensuring proper fluid flow. Its durable construction enhances the longevity of the component, reducing the need for frequent replacements. Additionally, it provides reliable performance under various operating conditions, supporting the overall reliability of the truck’s system.

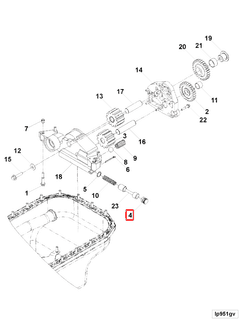

Installation Process

Installing the 3680696 Check Valve Plunger Stop requires careful attention to detail. The process involves securing the component in the correct position within the system, ensuring that it is properly aligned and tightened to the specified torque. Using the appropriate tools and following best practices will help ensure optimal performance and longevity of the part.

Common Issues and Troubleshooting

Common issues with the 3680696 Check Valve Plunger Stop may include leaks, improper fluid flow, or component failure. Troubleshooting these problems involves inspecting the component for signs of wear or damage, checking the alignment and tightness of the installation, and ensuring that the system is operating within the specified parameters. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s system.

Maintenance Tips

Routine maintenance of the 3680696 Check Valve Plunger Stop is important for keeping it in optimal condition. This includes regular inspections for signs of wear or damage, cleaning the component as necessary, and replacing it according to the manufacturer’s guidelines. Following these maintenance practices will help ensure the longevity and reliable performance of the part.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history, diverse product offerings, and commitment to innovation have made it a trusted name in the industry, providing solutions that enhance the performance and efficiency of commercial trucks.

Compatibility of Check Valve Plunger Stop (Part 3680696) with Cummins Engines

The Check Valve Plunger Stop, identified by the part number 3680696, is a critical component in the operation of several Cummins engine models. This part is integral to the engine’s functionality, ensuring the proper movement and sealing of the check valve plunger.

ISX Series Engines

The ISX series engines, including the ISX CM570, ISX CM870, ISX CM871, ISX15 CM2250, ISX15 CM2250 SN, ISX15 CM2350 X101, are designed for heavy-duty applications. The Check Valve Plunger Stop (3680696) is compatible with these engines, ensuring efficient operation of the check valve mechanism. This component is essential for maintaining the integrity of the engine’s lubrication and fuel systems.

QSX Series Engines

The QSX series engines, such as the QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105, are engineered for high-performance applications. The Check Valve Plunger Stop (3680696) fits seamlessly into these engines, providing the necessary support and control for the check valve plunger. This ensures optimal engine performance and longevity.

X15 Series Engines

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are designed for a range of applications, from medium to heavy-duty. The Check Valve Plunger Stop (3680696) is compatible with these engines, ensuring that the check valve operates smoothly and efficiently. This part is crucial for maintaining the engine’s overall performance and reliability.

Role of Part 3680696 Check Valve Plunger Stop in Engine Systems

The Check Valve Plunger Stop, identified as part 3680696, is integral to the operation of several engine components, ensuring efficient and reliable performance.

In the lubricating oil pump, the Check Valve Plunger Stop works in conjunction with the plunger mechanism to regulate the flow of lubricating oil. It prevents backflow, ensuring that oil is consistently delivered to critical engine components under pressure. This regulation is essential for maintaining proper lubrication, reducing friction, and enhancing the longevity of moving parts.

When incorporated into a lubricating pump kit, the Check Valve Plunger Stop enhances the overall efficiency of the lubrication system. It ensures that the pump operates within specified parameters, providing consistent oil delivery even under varying engine loads and speeds.

In an overhaul kit, the inclusion of the Check Valve Plunger Stop is vital for restoring the pump’s functionality to factory standards. It helps in recalibrating the pump’s performance, ensuring that all components work in harmony post-overhaul. This is particularly important for maintaining the precision required in high-performance engines.

For general pump applications within the engine system, the Check Valve Plunger Stop plays a supportive role in maintaining the integrity of the oil flow. It assists in stabilizing the pump’s operation, preventing issues such as oil starvation or excessive pressure buildup, which could lead to component failure.

Lastly, in the context of lubricating oil systems, the Check Valve Plunger Stop ensures that the oil remains within the intended flow paths. This is essential for preventing contamination and ensuring that the oil reaches all necessary components, thereby optimizing engine performance and reliability.

Conclusion

The Cummins 3680696 Check Valve Plunger Stop is a vital component in the operation of commercial trucks and Cummins engines. Its role in regulating fluid flow, ensuring proper lubrication, and maintaining system efficiency underscores its importance in the overall performance and reliability of these systems. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.