This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3063708 Starting Aid Tube is a component designed to enhance the start-up process of Cummins engines, particularly in heavy-duty trucks. Its role is to facilitate easier engine starts, especially under challenging conditions such as cold weather. This component is integral to the efficient operation of diesel engines, ensuring reliable performance when needed most.

Basic Concepts of Starting Aid Tubes

A Starting Aid Tube is a device used in diesel engines to assist in the initial start-up process. It works by providing an additional source of fuel or air to the engine, which helps in achieving the necessary combustion conditions for starting. In diesel engines, the starting process can be more demanding due to the reliance on compression ignition rather than spark ignition. The Starting Aid Tube plays a role in this process by ensuring that the engine receives the required fuel or air mixture to start smoothly and efficiently 1.

Purpose of the 3063708 Starting Aid Tube

The Cummins 3063708 Starting Aid Tube is specifically designed to aid in the start-up of Cummins engines, particularly in cold weather conditions. During cold starts, diesel engines may struggle to ignite due to lower temperatures, which can affect fuel viscosity and combustion efficiency. The Starting Aid Tube addresses this by providing an additional boost, ensuring that the engine starts reliably even in adverse conditions. This component is particularly beneficial for heavy-duty trucks, which often operate in environments where cold starts are common 2.

Key Features

The Cummins 3063708 Starting Aid Tube is characterized by several key features that enhance its performance. Its design is tailored to fit seamlessly within the Cummins engine system, ensuring compatibility and efficient operation. The tube is constructed from durable materials that can withstand the high pressures and temperatures encountered in diesel engines. Additionally, it may include unique attributes such as precise engineering to ensure optimal fuel or air delivery, contributing to its effectiveness in facilitating engine starts.

Benefits of Using the 3063708 Starting Aid Tube

The use of the Cummins 3063708 Starting Aid Tube offers several advantages. It improves starting reliability, making it easier to start the engine under various conditions, particularly in cold weather. This component reduces the strain on the engine during start-up, which can contribute to longer engine life and improved performance. Additionally, it enhances the overall efficiency of the starting process, ensuring that the engine reaches operating conditions more quickly and smoothly.

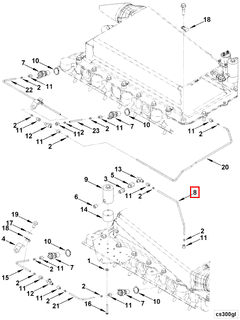

Installation and Integration

Installing the Cummins 3063708 Starting Aid Tube involves several steps and considerations to ensure proper integration into the engine system. It is important to follow manufacturer guidelines to ensure compatibility and correct installation. This may include checking for any prerequisites, such as ensuring the engine is compatible with the tube and that all necessary components are in place. Careful attention to these details helps in achieving optimal performance and reliability.

Troubleshooting Common Issues

Frequent problems associated with Starting Aid Tubes can include issues such as leaks, blockages, or malfunctions. These problems may arise due to wear and tear, improper installation, or environmental factors. Recommended troubleshooting steps include inspecting the tube for any signs of damage or wear, ensuring that all connections are secure, and checking for any obstructions that may affect its performance. Addressing these issues promptly can help maintain the efficiency and reliability of the starting process 2.

Maintenance and Care

Maintaining the Cummins 3063708 Starting Aid Tube is important to ensure optimal performance. Regular inspection routines should be conducted to check for any signs of wear, damage, or leaks. Cleaning procedures may be necessary to remove any buildup that could affect the tube’s performance. Additionally, following recommended replacement intervals can help prevent issues and ensure that the tube continues to function effectively. Proper maintenance contributes to the longevity and reliability of the component.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its high-quality engines and components. With a rich history of innovation and excellence, Cummins offers a wide range of products designed to meet the demanding requirements of various applications. The company’s reputation for reliability, performance, and durability makes it a preferred choice for professionals in the industry. Cummins continues to lead the way in providing solutions that enhance the efficiency and effectiveness of diesel engines.

Role of Part 3063708 Starting Aid Tube in Engine Systems

The part 3063708 Starting Aid Tube is an integral component in the operation of engine systems, particularly in facilitating the starting process under various conditions. This component is designed to work in conjunction with the starting aid system, which is essential for providing additional fuel or air to the engine during startup, especially in cold weather or when the engine is difficult to start.

Integration with Starting Aid System

The Starting Aid Tube is a conduit that directs the flow of starting aid fluid from the storage tank to the intake manifold. This fluid, often a volatile substance like ether, is introduced into the intake air stream to provide an additional source of fuel that is easily ignited. The Starting Aid Tube ensures a controlled and efficient delivery of this fluid, enhancing the engine’s ability to start promptly.

Interaction with Fuel Injection System

In modern engines equipped with fuel injection systems, the Starting Aid Tube plays a supportive role. When the starting aid is activated, the tube channels the fluid to a point where it can be effectively mixed with the air-fuel mixture created by the injectors. This additional fuel source helps to overcome the challenges posed by low temperatures or other conditions that might hinder a smooth start.

Coordination with Engine Control Unit (ECU)

The Starting Aid Tube also interacts with the Engine Control Unit (ECU), which monitors and controls the starting aid process. The ECU determines the appropriate time and duration for the starting aid to be deployed, based on sensor inputs such as temperature and engine load. The Starting Aid Tube must be precisely engineered to respond to these signals, ensuring that the starting aid is delivered exactly when needed.

Support for Air Intake System

The Starting Aid Tube is also closely linked with the air intake system. It is positioned to introduce the starting aid fluid at a point where it can be thoroughly mixed with the incoming air. This ensures that the additional fuel is evenly distributed throughout the combustion chambers, promoting a consistent and reliable start.

Enhancement of Overall Engine Performance

By facilitating a quicker and more reliable start, the Starting Aid Tube indirectly contributes to the overall performance and longevity of the engine. Smooth starts reduce wear on the starter motor and other components, leading to a more durable and efficient engine operation over time.

Conclusion

The Cummins 3063708 Starting Aid Tube is a vital component in the starting systems of Cummins engines, ensuring reliable and efficient starts under various conditions. Its integration with the starting aid system, fuel injection system, and ECU, along with its support for the air intake system, highlights its importance in enhancing overall engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.