This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3049041 Spring Retainer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the operation of commercial trucks, particularly in the context of engine functionality. Cummins, known for its commitment to quality and innovation, produces a range of components designed to enhance the performance and reliability of truck engines. The 3049041 Spring Retainer is one such component, playing a significant role in maintaining the efficiency and durability of truck engines.

Basic Concepts of Spring Retainers

A spring retainer is a mechanical component used to secure other parts in place within a system. In the context of truck engines, spring retainers are crucial for maintaining the proper positioning and function of various engine components. They work by holding springs and other parts in the correct alignment, ensuring that the engine operates smoothly and efficiently. The design and material of spring retainers are tailored to withstand the high stresses and temperatures encountered in engine environments 1.

Purpose of the 3049041 Spring Retainer

The 3049041 Spring Retainer is specifically designed to play a role in the operation of truck engines by securing components such as valves and springs. Its function is to ensure that these parts remain in the correct position under the dynamic conditions of engine operation. By maintaining the integrity of the valve train, the 3049041 Spring Retainer contributes to the overall functionality and performance of the engine, helping to achieve optimal combustion efficiency and reliability 2.

Key Features

The 3049041 Spring Retainer is characterized by its robust design and high-quality material composition. It is engineered to endure the demanding conditions within a truck engine, including high temperatures and mechanical stress. The retainer’s design incorporates features that enhance its performance and durability, ensuring long-term reliability in commercial truck applications.

Benefits

Utilizing the 3049041 Spring Retainer offers several advantages, including improved engine efficiency, enhanced reliability, and potential cost savings over time. By ensuring that engine components are securely held in place, this retainer contributes to smoother engine operation and reduced wear on related parts. Additionally, its durable construction minimizes the need for frequent replacements, offering long-term value to truck operators.

Installation Process

Installing the 3049041 Spring Retainer requires careful attention to detail to ensure proper fitting. The process involves using specific tools to align and secure the retainer in place within the engine assembly. Following manufacturer guidelines and best practices during installation is important to maintain the integrity of the engine’s valve train and ensure optimal performance.

Troubleshooting Common Issues

Common issues with spring retainers may include misalignment or damage, which can affect engine performance. Troubleshooting these problems involves inspecting the retainer and related components for signs of wear or displacement. Addressing these issues promptly can help maintain engine efficiency and prevent more significant problems from developing.

Maintenance Tips

Regular maintenance of the 3049041 Spring Retainer is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning to remove any debris that may affect its function, and replacing the retainer if necessary. Adhering to a maintenance schedule can help prevent unexpected engine issues and ensure consistent performance.

Compatibility and Usage

The 3049041 Spring Retainer is designed for use in specific types of trucks and engine models, ensuring compatibility with other components within the engine system. Its application is tailored to meet the demands of commercial truck engines, providing reliable performance in a variety of operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and quality. The company offers a wide range of products designed to enhance the performance and reliability of truck engines. Cummins’ commitment to quality is evident in its rigorous testing and development processes, ensuring that its components, including the 3049041 Spring Retainer, meet the high standards required for commercial truck applications 3.

Spring Retainer Part 3049041 Compatibility with Cummins Engines

The Spring Retainer part 3049041, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the integrity and functionality of the engine’s components by securely holding parts in place. Below is a detailed look at the compatibility of this part with various Cummins engines:

Mechanical Engines

- L10 MECHANICAL

- N14 MECHANICAL

- NH/NT 855

The Spring Retainer part 3049041 is compatible with several mechanical engines, including the L10 MECHANICAL, N14 MECHANICAL, and NH/NT 855. These engines are known for their robust design and reliability, often used in heavy-duty applications. The part ensures that the mechanical components remain securely fastened, contributing to the engine’s overall performance and longevity.

Select Engines

- M11 MECHANICAL

- M11 CELECT PLUS

The Spring Retainer part 3049041 also fits the M11 MECHANICAL and M11 CELECT PLUS engines. These engines are designed for versatility and efficiency, often used in a range of applications from construction to transportation. The part’s role in these engines is to maintain the precise alignment and secure attachment of various components, ensuring smooth operation and reducing the risk of mechanical failure.

High-Performance Engines

- K19

- K38

- K50

The Spring Retainer part 3049041 is also compatible with the high-performance K19, K38, and K50 engines. These engines are engineered for high power output and efficiency, commonly used in demanding applications such as marine and industrial settings. The part’s design ensures that the high-stress components are held firmly in place, contributing to the engine’s ability to perform under extreme conditions.

Advanced Engines

- 6B5.9

- V903

Lastly, the Spring Retainer part 3049041 fits the advanced 6B5.9 and V903 engines. These engines are equipped with advanced technology and features designed for superior performance and fuel efficiency. The part’s precision engineering ensures that the complex components of these engines remain securely fastened, supporting their advanced functionalities and reliability.

Role of Part 3049041 Spring Retainer in Engine Systems

The 3049041 Spring Retainer is an essential component that ensures the proper functioning of various engine systems by maintaining the integrity and performance of interconnected parts. Its application spans across multiple engine components, contributing to the overall efficiency and reliability of the engine.

Integration with Key Engine Components

Fuel System

In the fuel system, the 3049041 Spring Retainer is utilized in conjunction with the American Bosch Governor and Fuel Hardware. It helps in maintaining the precise tension required for the governor’s operation, ensuring consistent fuel delivery and regulation. This is particularly important in systems that employ Hydro-Mechanical Steps for fuel control, where the spring retainer ensures that the steps operate smoothly without undue wear or failure.

Injectors and Injector Systems

For Injectors and Injector Systems, the spring retainer plays a role in the mechanical linkage between the injector and the Cylinder Head. It ensures that the injector’s movement is controlled and consistent, which is vital for accurate fuel injection timing and quantity. This is especially relevant in high-performance engines where precision is paramount.

Timing Control Mechanisms

In Timing Control systems, such as those involving the Woodward PSG Governor and Timing Control Valve, the spring retainer is used to maintain the correct tension on springs that control the timing of fuel injection or valve operation. This ensures that the engine operates within its designed parameters, enhancing both performance and durability.

Valve and Piston Assemblies

Within the Connecting Rod and Piston assembly, the spring retainer is often found in the Oil Control Top Level Assembly Valve. Here, it helps in regulating oil flow to critical components, ensuring that the piston and connecting rod receive adequate lubrication without excess oil, which could lead to contamination or inefficient operation.

Cooling and Viscosity Systems

In Engine Cooling systems, particularly those involving an Aftercooler Core, the spring retainer might be used in conjunction with a Viscosity Sensor. It ensures that the sensor’s components are held in the correct position, allowing for accurate readings of oil viscosity, which is crucial for maintaining optimal engine temperature and performance.

Performance Parts and Kits

For EBM Performance Parts and Dual STC K38 Kits, the spring retainer is often included to enhance the durability and performance of modified engine components. It ensures that high-stress areas, such as those found in performance governors or step control valves, maintain their structural integrity under increased operational loads.

Summary of Component Interaction

The 3049041 Spring Retainer interacts with a variety of engine components to ensure that they operate within their designed parameters. Whether it’s maintaining tension in governors, ensuring precise fuel delivery, or regulating oil flow, the spring retainer is a fundamental part of many engine systems. Its role in these applications underscores the importance of using high-quality components to achieve optimal engine performance and longevity.

Conclusion

The 3049041 Spring Retainer is a vital component in the operation of commercial truck engines, ensuring the proper functioning and reliability of various engine systems. Its robust design and high-quality material composition make it suitable for the demanding conditions within a truck engine. By securing critical components in place, the 3049041 Spring Retainer contributes to improved engine efficiency, enhanced reliability, and potential cost savings over time. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term performance and durability in commercial truck applications.

SPECIFICATIONS

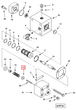

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.