This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

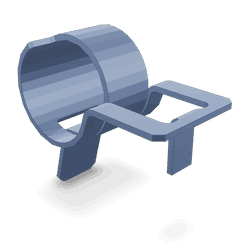

The Spring Hose Clamp 3923527 is a product manufactured by Cummins, a well-established name in the commercial truck industry. This clamp is designed for use in commercial trucks, where it plays a role in securing hoses and ensuring the proper flow of fluids within the truck’s systems.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to secure hoses to fittings. They consist of a metal band with a built-in spring that provides constant tension to maintain a secure fit. In automotive applications, these clamps are vital for maintaining the integrity of fluid transfer systems, including coolant, fuel, and hydraulic lines 1.

Purpose of the Spring Hose Clamp 3923527

The Spring Hose Clamp 3923527 is designed to secure hoses in commercial truck applications. It ensures that hoses remain firmly attached to their respective fittings, which is important for maintaining consistent fluid flow and preventing leaks. This clamp contributes to the overall reliability and performance of the truck’s fluid systems.

Key Features

The Spring Hose Clamp 3923527 is constructed from durable materials, ensuring longevity and resistance to corrosion. Its design includes a stainless steel band and a corrosion-resistant spring, which enhances its performance in demanding environments. The clamp also features a screw mechanism for easy adjustment, allowing for a precise fit on various hose diameters.

Benefits of Using Spring Hose Clamps

Spring hose clamps offer several advantages. They are known for their durability and resistance to wear and tear, which is particularly beneficial in the harsh conditions often encountered in commercial trucking. Additionally, they are easy to install and adjust, which simplifies maintenance procedures. Their design also allows for efficient fluid flow with minimal restriction 2.

Installation Process

To install the Spring Hose Clamp 3923527, first, ensure the hose is properly aligned with the fitting. Slide the clamp onto the hose, positioning it where needed. Use the screw mechanism to tighten the clamp until it achieves the desired tension. It is important to avoid over-tightening, as this can damage the hose. Regularly check the clamp to ensure it remains secure and properly adjusted.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks and improper sealing. If a leak is detected, first, ensure the clamp is properly tightened. If the problem persists, the clamp or hose may need to be replaced. Regular inspections can help identify wear or damage early, preventing more significant issues.

Maintenance Tips

Regular maintenance of the Spring Hose Clamp 3923527 involves checking for signs of wear or corrosion. Ensure the clamp remains securely fastened and adjust as necessary. Cleaning the clamp and surrounding areas can also help prevent buildup that might affect performance.

Safety Considerations

When installing or maintaining spring hose clamps, it is important to follow safety guidelines. Wear appropriate personal protective equipment, such as gloves and safety glasses. Ensure the truck’s engine is off and cooled down before beginning work. Be cautious of sharp edges on the clamp and hose fittings to avoid injury.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and innovative solutions. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial transportation 3.

Cummins Spring Hose Clamp 3923527 Compatibility

The Cummins Spring Hose Clamp part number 3923527 is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing hoses in place, ensuring a tight and reliable connection that can withstand the rigors of engine operation.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5 RGT

- G8.3

- GTA8.3 CM558

- ISB CM550

- ISB CM850

- ISF2.8 CM2220 F129

- ISV (Nissan)

- QSB4.5 CM850(CM2850)

- QSB5.9 44 CM550

Grouping of Compatible Engines

- QSB Series: QSB4.5 CM850(CM2850), QSB5.9 44 CM550

- ISB Series: ISB CM550, ISB CM850

- ISF Series: ISF2.8 CM2220 F129

- GTA Series: GTA8.3 CM558

- Others: 4B3.9, 6B5.9, 6C8.3, B4.5 RGT, G8.3, ISV (Nissan)

The Spring Hose Clamp 3923527 is engineered to provide a secure fit across these engines, ensuring that hoses remain firmly attached and do not come loose under the stress of engine vibrations and temperature fluctuations.

Role of Part 3923527 Spring Hose Clamp in Engine Systems

The Part 3923527 Spring Hose Clamp is an essential component in ensuring the secure and reliable connection of various hoses within engine systems. Its application spans across multiple critical areas, enhancing the overall performance and safety of the engine.

Crankcase Breather System

In the crankcase breather system, the spring hose clamp is used to connect the breather hose to the crankcase. This connection allows for the release of pressure built up within the crankcase, preventing damage and ensuring optimal engine performance.

Drain Locations

At drain locations, such as the fuel drain location and fuel drain tube, the spring hose clamp secures the hoses that facilitate the removal of contaminants and water from the fuel system. This ensures that the fuel supply remains clean and free from impurities.

Engine Coolant Vent

The engine coolant vent system relies on the spring hose clamp to maintain a secure connection between the coolant vent hose and the thermostat housing. This connection is vital for regulating pressure within the cooling system, preventing overheating, and ensuring efficient heat dissipation.

Exhaust Gas Recirculation Module

In the Exhaust Gas Recirculation (EGR) module, the spring hose clamp is employed to connect the exhaust recirculation hoses. This ensures that the recirculated exhaust gases are effectively mixed with the intake air, reducing emissions and improving engine efficiency.

Fuel System Components

Within the fuel system, the spring hose clamp plays a significant role in connecting various components such as the fuel filter assembly kit, fuel filter plumbing, fuel filter plumbing kit, and fuel supply tube. These connections are essential for maintaining the integrity of the fuel delivery system, ensuring a consistent and clean fuel supply to the engine.

Oil Fill Arrangement

The oil fill arrangement utilizes the spring hose clamp to secure the molded hose that connects to the oil fill port. This ensures that oil is efficiently transferred into the engine, maintaining proper lubrication and preventing leaks.

Pressure Sensor Connections

The spring hose clamp is also used to connect hoses to pressure sensors, ensuring accurate readings and reliable data for engine management systems. This is particularly important in systems where precise pressure monitoring is required for optimal performance.

Retro-Breather Kits

In retro-breather kits, such as the front retro-breather and tappet retro-breather, the spring hose clamp secures the hoses that facilitate the breather function. This helps in maintaining a balanced pressure within the engine compartments, enhancing overall engine reliability.

Flexible and Plain Hose Kits

Both flexible hose and plain hose kits benefit from the use of the spring hose clamp. These connections are vital in scenarios where hoses need to withstand vibrations, temperature fluctuations, and varying pressures, ensuring durable and secure connections throughout the engine system.

Conclusion

The Spring Hose Clamp 3923527 by Cummins is a critical component in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its durable construction, ease of installation, and compatibility with a wide range of Cummins engines make it an essential part for ensuring reliable engine performance. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.