3909395

Spring Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 10

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

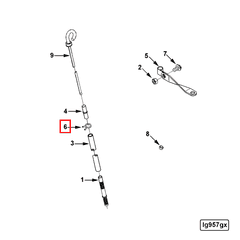

The Spring Hose Clamp 3909395, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is part of this extensive lineup, playing a role in ensuring the secure connection of hoses in various truck systems.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical fasteners used to create a secure seal between a hose and its mating component, such as a pipe or fitting. They consist of a metal band with a built-in spring that provides constant tension, ensuring a tight fit. These clamps are widely used in automotive and industrial applications to maintain the integrity of fluid transfer systems, including fuel, coolant, and air intake systems 1.

Role of the Spring Hose Clamp in Truck Operations

In the context of truck operations, the 3909395 Spring Hose Clamp serves to secure hoses in critical systems. It is applied in fuel lines to prevent leaks that could lead to fuel loss or hazardous conditions. In the coolant system, it ensures that the hoses remain firmly attached, maintaining efficient engine cooling. Additionally, in the air intake system, the clamp helps to secure hoses that deliver air to the engine, contributing to optimal performance 2.

Key Features of the 3909395 Spring Hose Clamp

This part is constructed from high-quality materials that offer durability and resistance to corrosion. Its design includes a stainless steel band for strength and a spring mechanism that provides consistent clamping force. The clamp is also engineered with ease of installation in mind, featuring a screw mechanism that allows for quick adjustments to achieve the desired tension.

Benefits of Using the 3909395 Spring Hose Clamp

Employing this Cummins part in truck maintenance offers several advantages. The clamp’s design contributes to improved seal integrity, reducing the risk of leaks. Its ease of installation saves time during maintenance procedures. Furthermore, the clamp’s durable construction and reliable performance ensure long-term reliability, minimizing the need for frequent replacements.

Installation and Usage Guidelines

To install the 3909395 Spring Hose Clamp, first, ensure that the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it near the fitting. Use the screw mechanism to tighten the clamp until the hose is securely fastened to the fitting. It is important to achieve the correct tension to ensure a leak-proof seal without over-tightening, which could damage the hose.

Troubleshooting Common Issues

Common issues with spring hose clamps may include leaks due to improper tension or corrosion. To address leaks, check the clamp’s tension and adjust as necessary. If corrosion is present, consider replacing the clamp with a new one to ensure a secure seal. Regular inspection can help identify and resolve these issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the longevity and effectiveness of the 3909395 Spring Hose Clamp, regular maintenance is recommended. Inspect the clamp and hose connections at routine intervals for signs of wear, corrosion, or leaks. Clean the clamp and hoses as needed to remove any buildup that could affect performance. Follow manufacturer guidelines for replacement intervals to maintain system integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range supports the needs of various industries, contributing to the efficiency and performance of heavy-duty vehicles worldwide 4.

Compatibility of the 3909395 Spring Hose Clamp with Cummins Engines

This part, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for securing hoses and ensuring a tight seal, which is critical for maintaining engine performance and preventing leaks. Here is a detailed breakdown of the engines with which this part is compatible:

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B5.9 G

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

- C8.3 G

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9G CM2180

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISC CM554

- ISC CM850

- ISL CM2150

- ISL CM554

- ISL G CM2180

Grouping of Compatible Engines

ISB Series

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9G CM2180

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

ISC Series

- ISC CM554

- ISC CM850

ISL Series

- ISL CM2150

- ISL CM554

- ISL G CM2180

Other Models

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5

- B5.9 G

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

- C8.3 G

This comprehensive compatibility ensures that the 3909395 can be used across a wide range of Cummins engines, providing a reliable solution for securing hoses and maintaining engine integrity.

Role of the 3909395 Spring Hose Clamp in Engine Systems

The Spring Hose Clamp, identified as part 3909395, is integral to maintaining the integrity and efficiency of various engine systems. It ensures secure connections between hoses and components, preventing leaks and maintaining system pressure.

In the context of the dipstick system, the clamp secures hoses that may be used for automated oil level checking systems, ensuring accurate readings and preventing oil spillage.

For the filter system, it plays a role in securing hoses connected to the filter housing, ensuring a tight seal that prevents bypass of contaminants and maintains filtration efficiency.

In the lubricating oil system, the clamp is used to secure hoses that transport oil to various engine components, ensuring consistent lubrication and preventing oil starvation in critical areas.

Regarding the fuel drain location, the clamp secures hoses used for draining fuel, ensuring that the process is clean and efficient, minimizing the risk of fuel spills.

In systems involving gauges, such as the oil level gauge, the clamp secures hoses that connect to the gauge, ensuring accurate pressure readings and maintaining the integrity of the gauge system.

For the oil level system, the clamp is used to secure hoses that may be part of an automated oil level monitoring system, ensuring that the system functions correctly and provides accurate oil level readings.

In the context of drain systems, whether for oil or fuel, the clamp secures hoses used in the draining process, ensuring that the operation is conducted safely and efficiently.

Lastly, for the oil level gauge location, the clamp ensures that any hoses connected to the gauge are securely fastened, maintaining the accuracy of the oil level readings and the overall functionality of the gauge system.

Conclusion

The 3909395 Spring Hose Clamp is a vital component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its role in securing hoses across various engine systems ensures the integrity and efficiency of these systems, preventing leaks and maintaining system pressure. Regular maintenance and proper installation of this part are essential to ensure its longevity and effectiveness in truck operations.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Gus Wright, Fundamentals of Medium-Heavy Duty Diesel Engines, Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.