This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

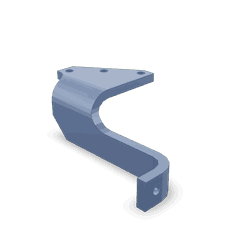

The Spring Bracket 3251051, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty vehicles. This Cummins part is integral to the suspension system of trucks, contributing to the overall efficiency and safety of the vehicle.

Basic Concepts of Spring Brackets

Spring brackets are components used in vehicle suspension systems to secure leaf springs to the vehicle frame. They play a role in maintaining the alignment and integrity of the suspension system by providing a stable mounting point for the springs. These brackets interact with various suspension components, including the leaf springs, frame, and shock absorbers, to ensure smooth and controlled vehicle movement over different terrains 1.

Purpose of Spring Bracket 3251051

The Spring Bracket 3251051 is specifically designed to support the leaf springs in the suspension system of a truck. Its role is to securely attach the springs to the truck’s frame, allowing for efficient load distribution and absorption of road shocks. This contributes to the truck’s overall performance by ensuring a stable and comfortable ride, even when carrying heavy loads or navigating rough roads 2.

Key Features

This part is characterized by its robust material composition, typically made from high-strength steel to withstand the stresses of heavy-duty use. Its design includes precise engineering to ensure a snug fit and secure attachment to the vehicle frame. Additionally, the bracket may feature corrosion-resistant coatings to enhance its durability in various operating environments.

Benefits

The use of the Spring Bracket 3251051 offers several advantages. It contributes to improved load handling capabilities, ensuring that the truck can carry heavier loads without compromising stability or ride quality. The bracket’s durable construction enhances the longevity of the suspension system, reducing the need for frequent replacements. Furthermore, a well-maintained suspension system can contribute to fuel efficiency by ensuring the truck operates smoothly and with minimal resistance 3.

Installation and Compatibility

Proper installation of the Spring Bracket 3251051 is crucial for its effective function. The process involves securing the bracket to the vehicle frame using the appropriate fasteners and ensuring it is aligned correctly with the leaf springs. It is important to follow manufacturer guidelines for installation to ensure compatibility with the specific truck model and configuration. Tools required may include wrenches, sockets, and possibly a torque wrench to ensure fasteners are tightened to the correct specifications.

Maintenance and Troubleshooting

Routine maintenance of the Spring Bracket 3251051 involves inspecting it for signs of wear, corrosion, or damage. Regular checks can help identify issues before they lead to more significant problems. Common issues may include loose fasteners or corrosion, which can be addressed by tightening fasteners or applying a protective coating, respectively. If the bracket shows signs of significant wear or damage, it should be replaced to maintain the integrity of the suspension system.

Safety Considerations

When working with the Spring Bracket 3251051, it is important to observe safety guidelines to prevent accidents or injuries. This includes ensuring the vehicle is securely supported on jack stands before beginning any work, wearing appropriate personal protective equipment, and following all manufacturer safety recommendations. Regular inspections and maintenance are also crucial to identify and address potential safety hazards before they result in operational issues.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, designed to meet the demanding requirements of heavy-duty applications. Cummins’ focus on quality and customer satisfaction underscores its position as a trusted partner in the commercial vehicle sector.

Role of Part 3251051 Spring Bracket in Engine Systems

The Spring Bracket 3251051 is an essential component in the orchestration of various engine systems, ensuring the seamless operation of interconnected parts. It primarily interfaces with the drive system, where it supports the mechanical linkage that transfers power from the engine to the fan. This bracket provides the necessary rigidity and stability to the drive mechanism, allowing it to operate efficiently under varying engine loads.

In conjunction with the fan, the Spring Bracket plays a supportive role by maintaining the alignment and tension of the fan belt. This ensures that the fan operates at optimal speed, effectively managing engine temperature by dissipating heat as required.

The interaction with the fan idler is another significant aspect of the Spring Bracket’s function. The idler pulley, which adjusts the tension in the fan belt, relies on the Spring Bracket for proper positioning and support. This relationship is vital for the longevity and performance of the belt, as it prevents slippage and undue wear.

Lastly, the Spring Bracket works in tandem with the spring support bracket to absorb vibrations and shocks transmitted through the engine’s operation. This dampening effect is important for the overall stability of the engine components, contributing to a smoother and more reliable performance.

Conclusion

The Spring Bracket 3251051 is a vital component in the suspension and engine systems of commercial trucks, offering robust support, efficient load distribution, and enhanced durability. Its precise engineering and durable construction contribute to the overall performance, safety, and reliability of heavy-duty vehicles. Regular maintenance and adherence to safety guidelines are essential to ensure the longevity and effectiveness of this part in demanding operational environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.