This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

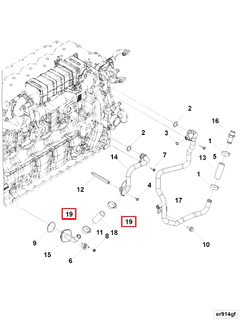

The Spring Hose Clamp (Part #5335619) by Cummins is a component in the maintenance and operation of commercial trucks. Cummins, a manufacturer in the automotive industry, produces this clamp to ensure reliable and efficient hose connections in various truck systems. This clamp is designed to meet the demanding requirements of commercial truck applications, providing a secure and durable solution for hose management.

Basic Concepts and Functionality

A spring hose clamp is a type of fastener used to secure hoses in automotive and industrial systems. It consists of a metal band with a built-in spring mechanism that allows it to expand and contract, providing a tight and consistent grip around the hose. The clamp operates by using a screw or worm gear to adjust the tension, ensuring a snug fit that prevents leaks and maintains the integrity of the hose connection. In automotive systems, spring hose clamps play a role in securing hoses for coolant, fuel, brake, and other fluid systems 1.

Purpose of the Spring Hose Clamp in Truck Operations

This Cummins part plays a specific role in the operation and maintenance of commercial trucks by ensuring secure and leak-free connections in various fluid systems. It is used to attach hoses to fittings in the engine cooling, fuel delivery, and brake systems, among others. The clamp’s design allows it to withstand the vibrations and harsh conditions typical in truck operations, maintaining a reliable seal and contributing to the overall efficiency and safety of the vehicle.

Key Features

The Spring Hose Clamp by Cummins features several design elements that enhance its performance and reliability. These include a corrosion-resistant metal band that provides durability in various environments, a robust spring mechanism that ensures consistent tension, and an adjustable screw or worm gear for precise fitting. The clamp is also designed to be easy to install and remove, facilitating maintenance and repairs.

Benefits of Using Spring Hose Clamps

Incorporating spring hose clamps in truck systems offers several advantages. These clamps provide durable and secure connections that resist vibrations and maintain a consistent seal, reducing the risk of leaks. They are easy to install, requiring minimal tools and time, which enhances maintenance efficiency. Additionally, spring hose clamps are versatile and can be used in a wide range of applications, making them a practical choice for commercial truck operations.

Installation Process

To ensure optimal performance and longevity, the Spring Hose Clamp should be installed following these steps:

- Clean the hose and fitting to remove any dirt or debris.

- Slide the clamp onto the hose, ensuring it is positioned correctly.

- Place the hose onto the fitting, aligning it properly.

- Use the screw or worm gear to tighten the clamp, adjusting the tension until the hose is securely in place.

- Double-check the connection for any signs of leaks or looseness.

Troubleshooting Common Issues

Frequent problems associated with spring hose clamps include leaks, loose connections, and corrosion. Potential causes may be improper installation, wear and tear, or exposure to harsh environments. Recommended solutions include re-tightening the clamp, replacing worn-out clamps, and using corrosion-resistant materials to enhance durability.

Maintenance Tips

To prolong the service life and ensure consistent performance of spring hose clamps, consider the following maintenance tips:

- Regularly inspect clamps for signs of wear, corrosion, or damage.

- Clean clamps and hoses to remove dirt and debris that may affect performance.

- Replace clamps as needed to prevent leaks and maintain secure connections.

- Ensure proper installation to avoid loose connections and potential leaks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture. Cummins’ commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Cummins Engine Part 5335619: Spring Hose Clamp Compatibility

The Spring Hose Clamp part 5335619, manufactured by Cummins, is a versatile component designed to secure hoses and pipes in various engine systems. This part is engineered to provide a reliable and efficient sealing mechanism, ensuring that connections remain tight and leak-free under operational conditions.

Compatibility with Cummins Engines

The Spring Hose Clamp part 5335619 is compatible with several Cummins engine models, including:

- B6.7 CM2350

- B135B

- ISBE4 CM850

B6.7 CM2350 and B135B

In the B6.7 CM2350 and B135B engines, the Spring Hose Clamp part 5335619 is often used to secure fuel lines, coolant hoses, and other critical fluid lines. These engines are known for their robust design and high performance, making the reliable sealing provided by this clamp essential for maintaining system integrity and preventing leaks.

ISBE4 CM850

The ISBE4 CM850 engine also benefits from the use of the Spring Hose Clamp part 5335619. This engine, typically used in heavy-duty applications, requires components that can withstand high pressure and temperature variations. The spring clamp ensures that hoses remain securely fastened, which is crucial for the engine’s overall performance and longevity 2.

Application Considerations

When installing the Spring Hose Clamp part 5335619 in any of these engines, it is important to ensure that the clamp is properly sized for the specific hose or pipe it is securing. Proper installation techniques should be followed to maximize the clamp’s effectiveness and longevity. Regular inspection and maintenance of the clamps are also recommended to detect any signs of wear or damage early, ensuring continued reliable performance.

Conclusion

The Spring Hose Clamp (Part #5335619) by Cummins is a vital component for maintaining secure and leak-free hose connections in commercial trucks. Its design and features make it suitable for various applications, ensuring durability and efficiency in truck operations. Proper installation, regular maintenance, and understanding its compatibility with specific Cummins engine models are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.