This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

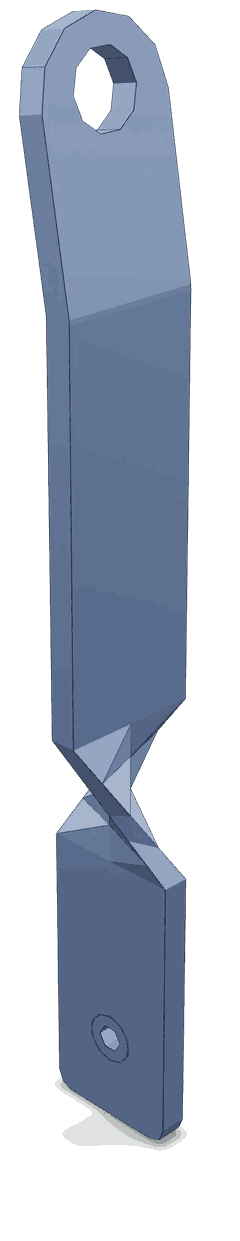

The Cummins 4063040 Spring Retainer is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s valve train system, contributing to the overall efficiency and reliability of the engine. Understanding its purpose and operation is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Spring Retainers

A spring retainer is a mechanical component used to hold valve springs in place within an engine. Its primary function is to ensure that the valve springs remain correctly positioned and operational, allowing the valves to open and close as intended 1. In the context of a truck’s engine, the spring retainer plays a role in maintaining the integrity of the valve train system, which is important for the engine’s combustion process.

Purpose of the Cummins 4063040 Spring Retainer

The Cummins 4063040 Spring Retainer is specifically designed to secure the valve springs in Cummins engines. It ensures that the springs apply consistent pressure to the valves, allowing them to seal properly during combustion and exhaust cycles. This component contributes to the engine’s ability to operate smoothly and efficiently by maintaining the precise timing and sealing of the valves.

Key Features

The Cummins 4063040 Spring Retainer is engineered with specific design and material characteristics to enhance its effectiveness and durability. It is typically made from high-strength materials to withstand the high stresses and temperatures within the engine environment. Its design includes features that ensure a secure fit and reliable operation under varying engine conditions.

Benefits

Utilizing the Cummins 4063040 Spring Retainer offers several advantages. It contributes to improved engine performance by ensuring that the valve springs function correctly, leading to better valve sealing and timing. This can result in enhanced engine efficiency and power output. Additionally, the durability of the retainer supports the engine’s reliability and longevity, reducing the likelihood of valve train failures.

Installation Process

Installing the Cummins 4063040 Spring Retainer requires careful attention to detail to ensure proper function. The process involves placing the retainer over the valve spring, ensuring it is correctly aligned and seated. Tools such as spring compressors may be necessary to safely and effectively install the retainer. Following the manufacturer’s guidelines for installation is recommended to achieve optimal results.

Troubleshooting Common Issues

Common issues with spring retainers can include improper seating, which may lead to valve train noise or performance issues. Diagnosing these problems involves inspecting the retainer for signs of wear or damage and ensuring it is correctly installed. Addressing these issues promptly can prevent more significant engine problems and maintain the efficiency of the valve train system.

Maintenance Tips

Regular maintenance of the Cummins 4063040 Spring Retainer is important for ensuring optimal performance and longevity. This includes periodic inspection for wear or damage and ensuring it remains securely in place. Following the manufacturer’s maintenance schedule and guidelines can help prevent issues and extend the life of the component.

Compatibility and Usage

The Cummins 4063040 Spring Retainer is designed for specific Cummins engine models. It is important to verify compatibility with the engine and truck model to ensure proper fit and function. Specific usage notes may include recommendations for installation procedures or maintenance practices tailored to the component’s application in heavy-duty trucks.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range includes engines for on-highway, off-highway, and industrial applications, as well as filtration and power generation systems. Cummins is recognized for its commitment to quality, performance, and customer satisfaction in the automotive industry.

Cummins Spring Retainer 4063040 Compatibility

The Cummins Spring Retainer part number 4063040 is designed to be compatible with a range of Cummins engines, ensuring secure and reliable performance across various applications. This part is integral to the engine’s operation, providing support and functionality.

G855 and KTA19GC Engines

The Spring Retainer 4063040 is specifically engineered to fit seamlessly with the G855 and KTA19GC engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as industrial machinery and power generation. The retainer ensures that critical components remain securely in place, contributing to the overall reliability and longevity of the engine.

N14 G Engine

Similarly, the N14 G engine benefits from the use of the Cummins Spring Retainer 4063040. This engine is widely recognized for its durability and efficiency, making it a popular choice in various sectors, including transportation and construction. The retainer plays a role in maintaining the integrity of the engine’s internal components, ensuring smooth operation and reducing the risk of mechanical failure.

By integrating the Spring Retainer 4063040 into these engines, Cummins ensures that users can rely on a consistent and high-quality performance, regardless of the specific engine model. This compatibility highlights Cummins’ commitment to providing parts that meet the rigorous demands of their engines.

Role of Part 4063040 Spring Retainer in Engine Systems

In the context of engine systems, the 4063040 Spring Retainer is an integral component that ensures the proper functioning of several key elements.

Governor Systems

Within governor systems, the 4063040 Spring Retainer is employed to maintain the integrity and alignment of spring-loaded mechanisms. It secures springs in place, ensuring they operate within their designed parameters. This is particularly important in mechanical governors where precise spring tension is necessary for accurate fuel delivery and engine speed regulation. The retainer prevents spring displacement, which could otherwise lead to inconsistent governor performance and potentially erratic engine behavior.

Fuel Systems

In fuel systems, especially those utilizing mechanical components, the 4063040 Spring Retainer plays a supportive role. It is often found in fuel injection systems where springs are used to control the timing and quantity of fuel delivery. By retaining these springs, the component ensures that fuel injectors open and close at the correct moments, maintaining optimal fuel-air mixture and engine efficiency.

Mechanical Components

Across various mechanical components within engine systems, the 4063040 Spring Retainer provides essential support. Whether in valve trains, where springs control valve operation, or in other spring-dependent mechanisms, the retainer ensures that springs remain in their intended positions. This reliability is fundamental for the consistent operation of mechanical parts, contributing to the overall stability and performance of the engine.

Conclusion

The Cummins 4063040 Spring Retainer is a critical component in the maintenance and optimization of heavy-duty truck engines. Its role in securing valve springs ensures the efficient operation of the valve train system, contributing to engine performance and reliability. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.