This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

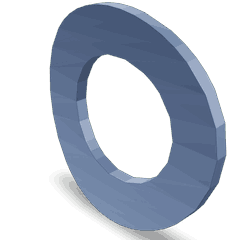

The Spring Washer 4025373, a specialized component from Cummins, is integral to the fastening systems in commercial trucks. Designed to enhance performance and reliability, this part ensures that bolts and nuts maintain their integrity under varying load conditions, contributing to the safety and efficiency of truck operations 1.

Basic Concepts of Spring Washers

Spring washers, or lock washers, are mechanical devices that prevent fastening elements like bolts and nuts from loosening due to vibration or fluctuating loads. They apply constant tension to the fastener, ensuring a secure connection. These washers are crucial in mechanical systems where vibration and dynamic loads are present 2.

Purpose of Spring Washer 4025373 in Truck Operations

This Cummins part is engineered to address the unique challenges of commercial trucks. It mitigates the risk of fastener loosening due to stress and vibration, ensuring that critical parts remain securely fastened throughout the vehicle’s operational life 3.

Key Features

The Spring Washer 4025373 is constructed from high-strength materials for durability. Its helical coil design provides consistent tension, effectively locking the fastener in place. It is versatile, accommodating a range of bolt sizes for various applications within the truck’s mechanical system 4.

Benefits of Using Spring Washer 4025373

Incorporating this part into truck maintenance routines offers advantages such as improved load distribution, enhanced fastening security, and extended longevity of fasteners, contributing to overall cost savings 5.

Installation Guidelines

For optimal performance, install the Spring Washer 4025373 according to specific guidelines. Select the appropriate size, place it under the nut or bolt head, and tighten to the manufacturer’s specified torque settings. Regular inspection is recommended 6.

Troubleshooting Common Issues

Common issues with spring washers include deformation or failure under load, leading to fastener loosening. These can be caused by incorrect installation, incompatible washer size, or extreme conditions. Verify the installation procedure, use the appropriate size, and consider environmental factors 7.

Maintenance Tips

Regular checks and maintenance are vital for the longevity and reliable performance of the Spring Washer 4025373. Inspect for wear or deformation, replace if damaged, and keep the fastening area clean to prevent premature wear 8.

Cummins: A Brief Overview

Cummins Inc. is a global leader in power solutions, known for its commitment to quality, innovation, and customer satisfaction. Its extensive product range and focus on reliability make it a preferred choice in the commercial truck industry 9.

Conclusion

The Spring Washer 4025373 by Cummins is a vital component in commercial truck operations, offering enhanced fastening security, durability, and efficiency. Its proper installation, maintenance, and understanding of its role in various engine systems are essential for the optimal performance and safety of commercial trucks.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Vehicle Noise, Vibration and Sound Quality, Gang Sheng, SAE International, 2012.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Vehicle Noise, Vibration and Sound Quality, Gang Sheng, SAE International, 2012.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.