This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

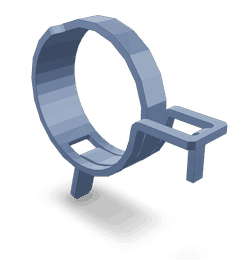

The Spring Hose Clamp 3697613, manufactured by Cummins, is a crucial component in the commercial truck industry. This part ensures the efficient operation of fluid systems in commercial trucks by maintaining secure connections in hose systems. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall reliability and performance of truck systems 4.

Basic Concepts and Functionality

A spring hose clamp is a device used to secure hoses to fittings in fluid systems. It operates by utilizing a metal band with a built-in spring that provides constant tension, ensuring a tight and secure fit around the hose. This type of clamp is commonly used in various applications where fluid transfer is necessary, including fuel, coolant, and hydraulic systems. The consistent pressure exerted by the spring helps maintain a leak-free connection, which is vital for the proper functioning of these systems 1.

Purpose and Role in Truck Operation

In the context of commercial trucks, the Spring Hose Clamp 3697613 serves a specific purpose by maintaining secure connections in hose systems. It ensures that hoses remain firmly attached to their respective fittings, preventing leaks and ensuring the efficient transfer of fluids. This is particularly important in environments where vibrations and harsh conditions are common, as it helps maintain the integrity of the fluid systems under stress 2.

Key Features

The Spring Hose Clamp 3697613 is characterized by several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes a robust spring mechanism that provides consistent tension, adapting to various hose diameters. Additionally, the clamp features easy-to-use fasteners that allow for quick installation and adjustment, making it a practical choice for maintenance and repair tasks 3.

Benefits

Using the Spring Hose Clamp 3697613 offers several advantages. Its reliable design ensures secure connections, reducing the risk of leaks and system failures. The ease of installation allows for efficient maintenance, minimizing downtime. Furthermore, its durability under various operating conditions makes it a long-lasting solution for commercial truck applications.

Installation and Usage Guidelines

Proper installation of the Spring Hose Clamp 3697613 involves several steps. First, ensure that the hose and fitting are clean and free from debris. Place the clamp around the hose, ensuring it is centered. Use the provided fasteners to secure the clamp in place, adjusting the tension as needed to achieve a snug fit. It is important to avoid over-tightening, as this can damage the hose. Regularly inspect the clamp to ensure it remains secure and functional.

Troubleshooting and Maintenance

Common issues with spring hose clamps include leaks and loose connections. Regular inspection and maintenance can help identify these problems early. If a leak is detected, check the clamp for proper tension and ensure the hose is not damaged. Maintenance practices include periodic tightening of the clamp and replacing it if signs of wear or corrosion are present. Following these guidelines can extend the lifespan of the clamp and ensure continued reliable performance.

Safety Considerations

When working with spring hose clamps, it is important to follow safety guidelines to prevent injuries. Wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to protect against sharp edges and potential fluid exposure. Handle the clamp carefully to avoid injuries from the spring mechanism. Additionally, ensure that the area is well-ventilated when working with fluid systems to avoid inhalation of harmful vapors.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. Their extensive product range caters to various applications, ensuring that customers receive solutions tailored to their specific needs 4.

Compatibility with Cummins Engines

The Spring Hose Clamp part number 3697613, manufactured by Cummins, is designed to fit a variety of Cummins engines. This clamp is essential for securing hoses and ensuring leak-free connections in various engine systems. Below is a detailed overview of the engines with which this part is compatible:

B6.7 CM2670 Engines

- B6.7 CM2670 B153B

- X11 CM2670 X126B

- X12 CM2670 X121B

- X13 CM2670 X122B

The Spring Hose Clamp part 3697613 is particularly suited for the B6.7 CM2670 engines, including the B153B, X126B, X121B, and X122B variants. These engines are known for their robust performance and reliability, and the clamp ensures that hoses remain securely fastened under various operating conditions.

ISG11 and ISG12 CM2880 Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

The ISG11 and ISG12 CM2880 engines, specifically the G108, G107, and CMOH6.0 G111 variants, also benefit from the use of the Spring Hose Clamp part 3697613. This clamp provides the necessary tension to maintain a tight seal on hoses, which is critical for the efficient operation of these engines.

QSG12/X12 CM2350 Engines

- QSG12/X12 CM2350 G110

For the QSG12/X12 CM2350 G110 engine, the Spring Hose Clamp part 3697613 is an ideal choice. It ensures that hoses are held firmly in place, preventing any leaks that could compromise engine performance.

X12N CMMDG1 Engines

- X12N CMMDG1 X143B

The X12N CMMDG1 X143B engine is another application where the Spring Hose Clamp part 3697613 is highly effective. This clamp is engineered to withstand the rigors of engine operation, providing a dependable solution for securing hoses.

By using the Spring Hose Clamp part 3697613 across these various Cummins engines, technicians and operators can ensure that their engine systems remain leak-free and operationally efficient.

Role in Engine Systems

The Spring Hose Clamp 3697613 is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight seal around hoses and tubes, preventing leaks and ensuring optimal performance.

Compressor Air Inlet Arrangement

In the compressor air inlet arrangement, the Spring Hose Clamp is utilized to secure the hoses that deliver air to the compressor. This arrangement is vital for maintaining the correct air-fuel ratio and ensuring that the compressor operates within its designed parameters. The clamp ensures that there are no air leaks, which could otherwise lead to inefficient compressor performance and potential damage over time.

Compressor Air Inlet Tube

The compressor air inlet tube is another area where the Spring Hose Clamp plays a significant role. By securing the tube firmly in place, the clamp prevents any disconnection or movement that could disrupt the airflow. This stability is essential for consistent compressor operation, as any fluctuation in airflow can affect the overall efficiency and reliability of the engine system.

Crankcase Breather

In the crankcase breather system, the Spring Hose Clamp is used to secure the hoses that vent pressure from the crankcase. Proper ventilation is necessary to prevent the buildup of pressure, which can lead to oil leaks and other mechanical issues. The clamp ensures that the breather hoses remain connected and sealed, allowing for the safe release of pressure and contaminants from the crankcase.

Overall, the Spring Hose Clamp 3697613 is integral to the maintenance of secure connections and seals within these engine components, contributing to the efficient and reliable operation of the entire engine system.

Conclusion

The Spring Hose Clamp 3697613 by Cummins is a vital component in the maintenance and operation of commercial truck fluid systems. Its robust design, ease of installation, and compatibility with various Cummins engines make it a reliable choice for ensuring secure and leak-free connections. Regular maintenance and proper installation are key to maximizing the lifespan and performance of this part, ultimately contributing to the overall efficiency and reliability of truck systems.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.