This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

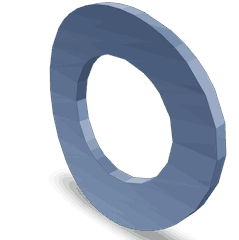

The 3420914 Spring Washer, a component manufactured by Cummins, is designed for use in commercial trucks. It plays a role in various mechanical assemblies by providing additional tension and preventing loosening of fasteners under dynamic loads, which is particularly important in the demanding environments of commercial trucking 1.

Basic Concepts of Spring Washers

Spring washers are specialized washers that incorporate a spring mechanism. Their primary function is to apply a constant tension to the fastener, which helps maintain the integrity of the joint under vibration and dynamic loads. This is in contrast to regular washers, which primarily serve to distribute the load and prevent damage to the surfaces in contact. Spring washers are typically made from materials such as stainless steel or carbon steel, chosen for their durability and resistance to deformation under stress 2.

Purpose of the 3420914 Spring Washer

This Cummins part is specifically engineered to enhance the stability and efficiency of components in commercial trucks. By providing a consistent clamping force, it helps to secure fasteners in place, even under the harsh vibrations and loads experienced during truck operation. This contributes to the overall reliability and safety of the truck’s mechanical systems 3.

Key Features

The 3420914 Spring Washer is characterized by its unique design, which includes a coiled spring that exerts a constant force on the fastener. It is constructed from high-quality materials, ensuring durability and performance in heavy-duty applications. Its design allows for flexibility in accommodating various fastener sizes and types, making it a versatile component in truck maintenance and assembly 4.

Benefits

Utilizing this part offers several advantages. It improves load distribution across the fastener, enhancing the joint’s stability. Its resistance to vibration helps prevent fastener loosening, a common issue in commercial trucks. Additionally, the washer’s durability ensures longevity, even in the face of harsh operating conditions, contributing to the overall reliability of the truck’s components.

Installation Considerations

Proper installation of the 3420914 Spring Washer is vital for its effective performance. It should be installed according to the manufacturer’s torque specifications to ensure the correct amount of tension is applied. Best practices include using the appropriate tools for installation and ensuring the washer is correctly oriented to exert the intended spring force. Following these guidelines helps maintain the washer’s effectiveness and durability.

Troubleshooting and Maintenance

Common issues with spring washers include deformation or failure under excessive load or corrosion. Regular inspection for signs of wear or damage is recommended to identify potential problems early. Maintenance practices, such as cleaning and proper storage, can help prolong the life of the 3420914 Spring Washer and ensure its continued reliable operation.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of innovation and quality in diesel engines and components. Their commitment to excellence is evident in the design and production of components like the 3420914 Spring Washer. Cummins’ reputation for reliability and performance makes their products a preferred choice for commercial truck applications, where durability and efficiency are paramount.

Spring Washer 3420914 Compatibility with Cummins Engines

The Spring Washer part number 3420914, manufactured by Cummins, is designed to provide a secure and reliable connection between different engine parts, ensuring optimal performance and longevity.

QSV81G, QSV91G, and QSW/QSV82 Engines

This part is compatible with the QSV81G, QSV91G, and QSW/QSV82 engines. These engines are part of Cummins’ range of industrial and power generation engines, known for their durability and efficiency. The spring washer ensures that the bolts and screws remain tight, preventing any loosening over time, which is crucial for maintaining the integrity of the engine’s components.

QSW27, QSW36, and QSW73 Engines

Similarly, the QSW27, QSW36, and QSW73 engines also benefit from the use of the Spring Washer 3420914. These engines are typically used in various applications, including construction and agricultural equipment. The spring washer’s design helps in absorbing vibrations and maintaining consistent pressure, which is essential for the smooth operation of these engines.

QSV91-G4 CM558/CM700 V102 and QSZ90 Engines

The QSV91-G4 CM558/CM700 V102 and QSZ90 engines are more advanced models in Cummins’ lineup. The Spring Washer 3420914 is integral to these engines as well, providing the necessary support and stability. These engines are often used in heavy-duty applications where reliability and performance are paramount. The spring washer’s role in these engines is to ensure that all parts remain securely fastened, contributing to the overall efficiency and lifespan of the engine.

Role of Part 3420914 Spring Washer in Engine Systems

The 3420914 Spring Washer is a versatile component that enhances the performance and reliability of various engine systems by providing additional tension and preventing loosening in dynamic environments.

Air Intake and Exhaust Systems

In the air intake assembly manifold and air outlet pipe, the spring washer helps maintain the integrity of connections by providing additional tension and preventing loosening due to vibrations. This ensures a consistent airflow, which is vital for optimal engine performance.

Assembly Flanges and Coolers

Within the assembly flange and charge air cooler assembly, the spring washer enhances the sealing efficiency. It counters the dynamic forces that could otherwise lead to leaks, thus maintaining the pressure and temperature balance necessary for efficient cooling and air charging.

Heat Exchangers

For the heat exchanger and its variants like the heat assembly L6 exchanger and heat assembly L8 exchanger, the spring washer plays a role in securing the connections between the exchanger components. This is important for maintaining the thermal efficiency and preventing coolant or air leaks.

Fuel and Lubrication Systems

In the fuel cleaner and lubricating oil assembly pump, the spring washer ensures that the connections remain tight under operational pressures. This is particularly important in the oil sub-assembly pan and lubricating oil pump where consistent pressure and flow are necessary to prevent engine wear and ensure smooth operation.

Starting and Flywheel Assemblies

The starting motor and various flywheel assemblies (housing, flywheel housing assembly, and flywheel mounting housing) benefit from the spring washer by securing bolts and nuts in high-vibration environments. This stability is essential for the reliable engagement and disengagement of the flywheel during engine start-up and operation.

Pressure Regulation and Miscellaneous Components

The pressure regulator valve and gear mounting housing also utilize the spring washer to maintain secure fittings. This is crucial for components that experience frequent changes in pressure and stress, ensuring they operate within specified parameters.

Conclusion

The 3420914 Spring Washer is a versatile and essential component that enhances the performance and reliability of various Cummins engines. Its application across different engine models underscores its importance in maintaining the structural integrity and operational efficiency of these engines.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.