This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

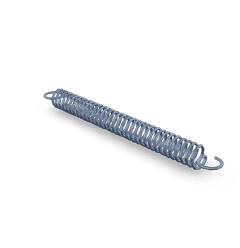

The Tension Control Spring 3285133, manufactured by Cummins, is a component designed for use in heavy-duty trucks. This spring plays a role in maintaining the tension within various mechanical systems of the truck. Tension control springs are vital in the automotive industry for ensuring the smooth operation of components that require consistent tension, such as belts, cables, and other moving parts. Cummins, a well-established name in the automotive sector, is known for producing high-quality components that enhance the performance and reliability of heavy-duty vehicles 1.

Basic Concepts of Tension Control Springs

Tension control springs are mechanical devices that store and release energy when deformed. They function by applying a consistent force to maintain tension in a system. These springs are commonly used in various applications, including automotive, industrial machinery, and consumer products. The principles of spring mechanics, such as Hooke’s Law, are relevant to understanding how tension control springs operate. Hooke’s Law states that the force needed to extend or compress a spring by some distance is proportional to that distance 2.

Purpose of the 3285133 Tension Control Spring

The 3285133 Tension Control Spring is specifically designed to play a role in the operation of heavy-duty trucks. It contributes to the functionality and performance of the truck by maintaining the necessary tension in critical components. This ensures that parts such as belts and cables operate smoothly and efficiently, which is vital for the overall performance of the vehicle 3.

Key Features

The 3285133 Tension Control Spring features a robust material composition, typically made from high-tensile steel, which provides durability and reliability. Its design specifications include precise dimensions and a helical coil structure that allows it to effectively store and release energy. Unique attributes of this spring may include corrosion-resistant coatings and specialized end configurations to ensure secure attachment within the truck’s mechanical systems.

Benefits

The 3285133 Tension Control Spring offers several benefits, including improved performance, durability, and reliability. By maintaining consistent tension, it contributes to the efficient operation of heavy-duty trucks. These benefits enhance the overall efficiency and safety of the vehicle, ensuring that critical components function as intended under various operating conditions.

Installation and Integration

Proper installation of the 3285133 Tension Control Spring is vital for optimal performance. Step-by-step instructions should be followed to ensure that the spring is correctly positioned and secured within the truck’s mechanical system. Best practices include verifying that all attachment points are clean and free of debris, and that the spring is not over-tightened, which could lead to premature wear or failure.

Troubleshooting and Maintenance

Common issues with tension control springs may include loss of tension, corrosion, or physical damage. Troubleshooting these issues involves inspecting the spring for signs of wear or damage and ensuring that it is properly installed. Maintenance tips to prolong the lifespan of the 3285133 Tension Control Spring include regular inspection, cleaning, and lubrication of attachment points, as well as replacing the spring if it shows signs of significant wear or failure.

Performance and Efficiency

The 3285133 Tension Control Spring enhances the performance and efficiency of heavy-duty trucks by ensuring that components requiring consistent tension operate smoothly. Data and examples illustrate its impact on truck operations, showing improved reliability and reduced maintenance needs when the spring is properly installed and maintained.

Safety Considerations

Safety considerations related to the use of tension control springs in heavy-duty trucks include the importance of proper installation, regular maintenance, and adherence to manufacturer guidelines. Ensuring that the spring is correctly installed and maintained helps prevent failures that could lead to safety hazards, such as belt slippage or cable breakage.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to quality and innovation. The company has a long history of producing reliable components for heavy-duty trucks. Cummins’ product line includes a wide range of components designed to enhance the performance and durability of vehicles. The company’s focus on heavy-duty truck components underscores its dedication to meeting the demanding needs of this sector.

Cummins Engine Part 3285133: Tension Control Spring

The Cummins part number 3285133, known as the Tension Control Spring, is a critical component in various Cummins engine models. This part is designed to maintain the proper tension within the engine’s belt system, ensuring optimal performance and longevity of the engine.

Application in Cummins Engines

The Tension Control Spring is integral to the belt drive system in several Cummins engine models. It is particularly relevant in the following engines:

- 6B5.9 Series: This engine series benefits from the precise tension control provided by the 3285133 spring. The spring ensures that the belts are neither too loose nor too tight, which helps in reducing wear and tear on the belt and the pulleys it engages with.

Importance of the Tension Control Spring

The primary function of the Tension Control Spring is to maintain consistent belt tension. This is crucial for several reasons:

- Prevents Belt Slippage: Proper tension ensures that the belts do not slip off the pulleys, which can lead to reduced efficiency and potential engine damage.

- Reduces Wear and Tear: By maintaining the correct tension, the spring helps in evenly distributing the load on the belt, thereby reducing wear and extending the lifespan of the belt and associated components.

- Enhances Performance: Consistent belt tension ensures that the engine’s ancillary systems, such as the alternator and air conditioning compressor, operate efficiently.

Installation and Maintenance

When installing the Tension Control Spring, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. Regular maintenance checks should be performed to inspect the spring for any signs of wear or damage. If the spring is found to be compromised, it should be replaced promptly to avoid any potential engine issues.

By understanding the role and importance of the Tension Control Spring in Cummins engines, technicians and engine operators can better maintain and troubleshoot their engine systems, ensuring reliable and efficient operation.

Role of Part 3285133 Tension Control Spring in Engine Systems

The part 3285133 tension control spring is an essential component in maintaining the proper function of various engine systems. Its primary role is to provide consistent tension, ensuring smooth and reliable operation of interconnected parts.

Interaction with the Lever Mechanism

In engine systems, the lever mechanism is often used to translate rotational motion into linear motion, or vice versa. The tension control spring, when integrated with the lever, helps in maintaining the desired tension across the lever arm. This ensures that the lever operates within its specified range of motion, preventing excessive play or binding. The consistent tension provided by the spring allows for precise control over the lever’s position, which is vital for accurate adjustments and reliable performance.

Contribution to Throttle Operation

The throttle is a key component in engine systems, responsible for regulating the airflow into the engine. The tension control spring plays a significant role in the throttle mechanism by ensuring that the throttle plate opens and closes smoothly and consistently.

When the throttle is engaged, the spring helps in maintaining uniform tension on the throttle linkage. This uniform tension prevents the throttle from sticking or moving erratically, which could lead to inconsistent engine performance. Additionally, the spring assists in returning the throttle to its default position when released, ensuring that the engine returns to idle smoothly.

By providing consistent tension, the part 3285133 tension control spring enhances the overall reliability and performance of both the lever and throttle mechanisms within engine systems.

Conclusion

The 3285133 Tension Control Spring is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its role in maintaining consistent tension across various mechanical systems ensures the smooth and efficient operation of critical components. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential to maximize the benefits of this Cummins part, ensuring reliable and safe vehicle performance.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.