3092254

Spring Hose Clamp

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Spring Hose Clamp 3092254, manufactured by Cummins, is a critical component in the commercial truck industry. This clamp is designed to secure hoses, ensuring the efficient transfer of fluids within the engine system.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to secure hoses to fittings. They consist of a metal band with a built-in spring that provides constant tension, ensuring a tight and secure fit 1. In automotive applications, these clamps are essential for maintaining the integrity of fluid transfer systems, including coolant, fuel, and hydraulic lines.

Purpose of the Spring Hose Clamp 3092254

This Cummins part is integral to the operation of a truck. It secures hoses in place, preventing leaks and ensuring that fluids are transferred efficiently throughout the system. This clamp helps maintain the pressure and flow necessary for the proper functioning of various truck systems.

Key Features

The Spring Hose Clamp 3092254 is constructed from high-quality materials, ensuring durability and reliability. Its design includes a corrosion-resistant finish, which enhances its performance in harsh environments. The clamp features a robust spring mechanism that provides consistent tension, ensuring a secure fit on hoses of varying diameters.

Benefits of Using Spring Hose Clamps

Spring hose clamps offer several advantages. They are known for their durability, capable of withstanding the rigors of commercial truck operations. Installation is straightforward, requiring minimal tools and time. Additionally, spring hose clamps are easy to maintain, with simple adjustments possible to accommodate changes in hose diameter or fitting size.

Installation Process

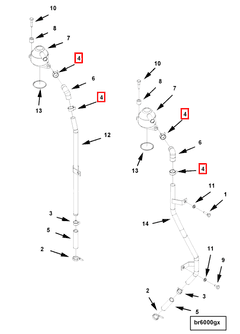

Installing the Spring Hose Clamp 3092254 involves several steps. First, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it over the fitting. Use a clamp plier to tighten the clamp until it achieves the desired tension, ensuring a secure fit without over-tightening, which could damage the hose.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks due to improper installation or wear and tear. To address these problems, check the clamp for proper tension and ensure it is correctly positioned on the hose and fitting. If wear is detected, replacing the clamp is recommended to prevent further issues.

Maintenance Tips

Regular maintenance of the Spring Hose Clamp 3092254 is key to its longevity and reliability. Inspect the clamp during routine checks for signs of corrosion, wear, or damage. Ensure the tension remains consistent and adjust as necessary. Cleaning the clamp and surrounding areas can also help prevent buildup that may affect performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation and quality in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles, ensuring reliability and performance 2.

Role of Part 3092254 Spring Hose Clamp in Engine Systems

This part is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight seal around hoses, preventing leaks and ensuring that fluids and gases are properly contained and directed within the engine.

Breather System

In the breather system, the Spring Hose Clamp is used to secure hoses that vent crankcase gases. These gases, which include unburned fuel and combustion byproducts, need to be expelled to maintain proper engine function. The clamp ensures that the breather hoses remain firmly attached, preventing any escape of these gases, which could lead to decreased engine performance and increased emissions.

Crankcase Ventilation

The crankcase ventilation system relies on secure hose connections to maintain pressure balance within the crankcase. The Spring Hose Clamp plays a key role here by ensuring that ventilation hoses are tightly sealed. This prevents any unwanted pressure build-up, which could lead to oil leaks or engine damage. Proper sealing also ensures that the Positive Crankcase Ventilation (PCV) system functions correctly, recirculating gases back into the intake manifold for efficient combustion.

Packaged Engine Systems

In packaged engine systems, where multiple components are integrated into a single unit, the Spring Hose Clamp is vital for maintaining the integrity of the hose connections. These systems often include complex routing of hoses for fuel, coolant, and ventilation. The clamp ensures that all connections are secure, reducing the risk of leaks and enhancing the reliability of the engine package.

Guard Systems

Engine guard systems, which protect various components from debris and environmental factors, often incorporate hoses for cooling or ventilation purposes. The Spring Hose Clamp is used to secure these hoses, ensuring they remain in place and function correctly despite the guard’s presence. This is particularly important in off-road or industrial applications where engines are exposed to harsh conditions.

Conclusion

The Spring Hose Clamp 3092254 is a fundamental component in maintaining the efficiency and reliability of engine systems by ensuring secure and leak-free hose connections across various applications. Its design and material quality make it suitable for the demanding conditions these engines operate under, providing long-lasting performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.